Laser Cut Eiffel Tower: Design Update 8 – Almost Done!

The initial shape of the Eiffel tower is just about done, just one more platform and final top section left to be done – yep, another CNCKing.com exclusive project update!

The Eiffel Tower is now made-up of 38 pieces and stands at 138cm tall using 4m thick material – my goal was roughly a meter tall, the top tower blew that out of the water – looking at about a meter and a half at this point.

I initially wanted a little elevator in there, I think that idea will have to be thrown into the garbage at this point – I just don’t have enough resolution to both double-up the top of the tower and ad an elevator that moves up-down along with the elevator shaft. The wee elevator would need to be very small and won’t be seen anyways through all the holes. If something serves no purpose, I chuck it out as part of my efficient design process!

I’ve outlined an issue that I had way back when I first started documenting this laser cut Eiffel Tower, that of vertices showing-up as full even though they were designed to be “empty” and it has stuck again! After many hours, I’m unable to get rid of this one, so I’ll just have to live with it. The model is accurate, it’s just the filled-in mesh that’s showing a filled-in area when in reality there isn’t a filled-in area. I don’t think many people will notice this.

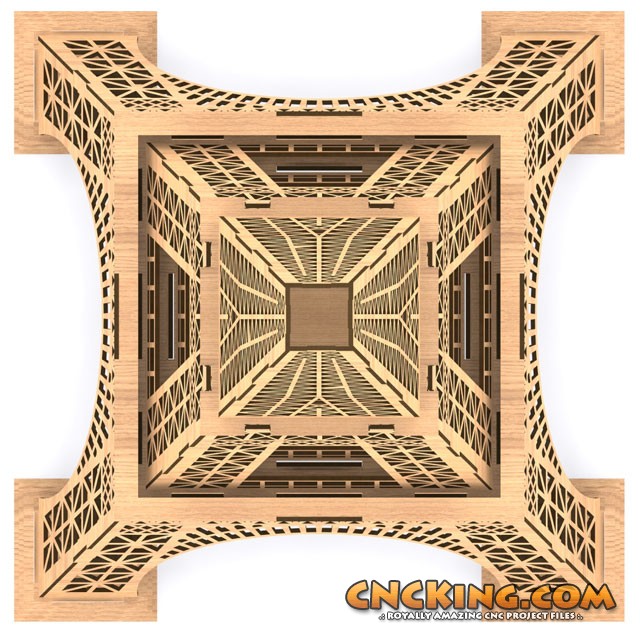

I’ve also included a render from the top looking down, it looks pretty neat – sometimes a render from another angle leads to the next design, in this case, I could easily create a really cool spaceship – a flying Eiffel tower with lots of modifications would look really neat!

There are lots of issues left to be resolved with this laser cut Eiffel Tower so before continuing to the final platform, I’m going to fix them so the model can be wrapped-up. I hope you can now see the major advantage CNCKing.com has when it comes to designing models, the only other way to build this model is trial and error with a laser cutter – it would have taken me a tremendous amount of time and money to build things to this point alone and I can guarantee, fatigue would set-in rather quickly as there are so many changes needed every step of the way, some are major, like changing the angle of a structure but others are down to 1mm deviations which are required for parts to fit correctly together. I know I’m dealing with wood (in my case) so there is some play but I prefer to have a solid design to begin with, there is enough room for error in the cutting and assembly process as it is!

The only thing that is wasted are poor and lonely electrons during my design process. The tree is still standing in the forest, the water is still flowing-up to the leaves and the chipmunks that call their nest home in the base are all intact – at least when a tree is fallen in the name of a CNCKing.com cutter, it’s used and not wasted in countless R&D efforts.

Building a building like this should be fun, not a tedious chore!