Custom CNC Laser Downdraft Table: Design (Part 2)

In the previous blog post, I showed the initial steps involved with creating a custom laser cut downdraft table, today we’ll continue through that design adventure.

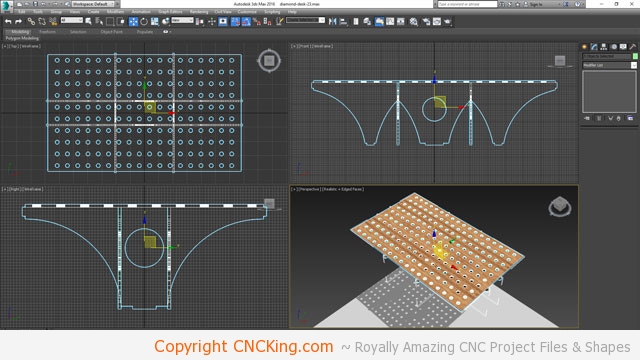

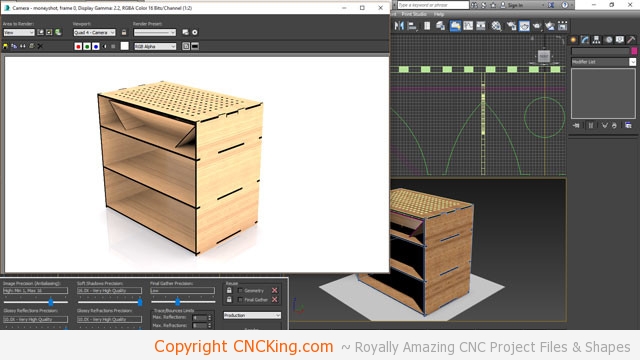

I’ve now made the table with holes for the draft table and they work perfectly with the underlying supports, so none of the holes are blocked by them. Now I’ll begin building the sides of the table. The top surface will not be plywood but I think I’ll use 12 mm (1/2 inch) MDF instead for strength purposes and to prevent scratching the pieces I put on this table. MDF is also porus, which means air will flow through it to hold down the piece somewhat.

Plywood is too hard and can’t really be sanded while acrylic has static cling issues with dust and no easy way to remove the scratches. The dimensions of the table are 82 x 50 cm with each hole measuring 0.9 cm in diameter.

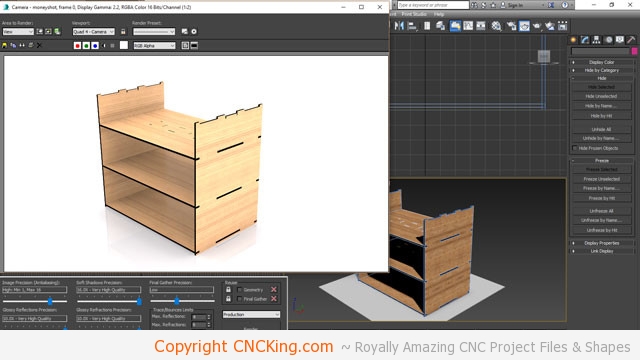

It’s been a few weeks since I last looked at this design, I wanted to see how my CNC laser station design I made earlier worked-out and if there were any lessons I can learn from that set-up which I can apply to this custom downdraft table. Although I had 6 mm (1/4 inch) MDF on the CNC laser station, it has actually surprised me by how stable it is and as such, this downdraft table will be made from MDF exclusively, half inch (12 mm) for the structure, 1/4 inch (6 mm) for the shelving. There will be a lot of pressure on this from the sanding process so it NEEDS to be heavy and strong and as it will have caster wheels, that won’t be too much of an issue.

Another thing I’m seriously considering is also creating a jig on the surface that will allow this table to also function as a routing table. Yes, I have a ShopBot Desktop CNC router but sometimes, a regular router is more efficient workflow wise. As this is already a downdrafting table, all the dust will be sucked-up anyhow.

To make this as simple as possible, I’ll be using a simple drop and slot method that I’ve used to create hundreds of CNC toys and furniture in the past. It makes assembly a breeze, everything is incredibly strong and only glue is required to keep everything together without any nails.

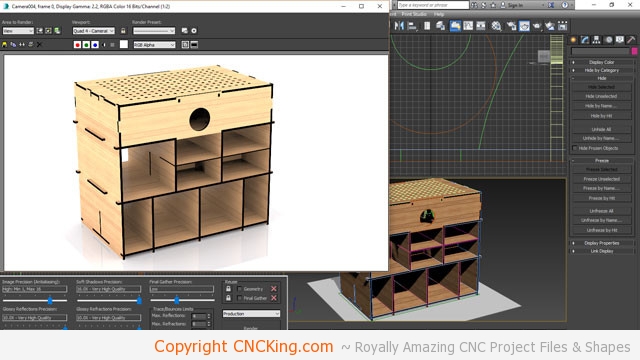

The first step is establishing the sides of the design, this will use 12 mm (1/2 inch) MDF, one on each side and a doubled-up one in the center followed by 2-4 horizontal MDF pieces of the same thickness. I’ll then integrate 6 mm MDF shelving – as this is a downdrafting table, I want all my sanding tools and supplies held in this table. This makes thing efficient and also keeps dust to a minimum as anything dusty is all together.

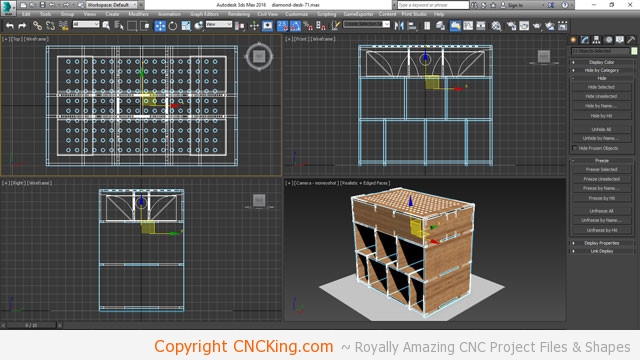

As I want to keep the solid pieces of MDF as “together” as possible, I’ll have the internal separators that help to support the downdrafting pressures above actually slot in through the front towards the rear. This means I get the strength I need and support without having to cut things up into smaller increments.

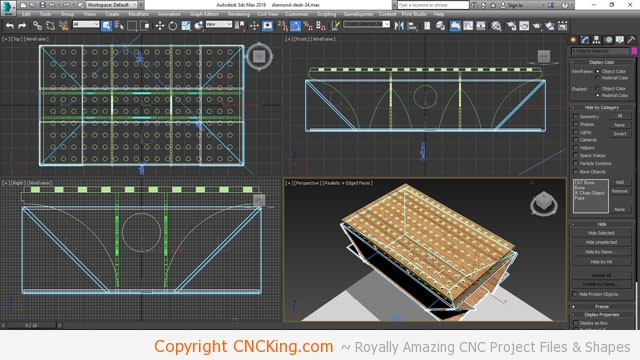

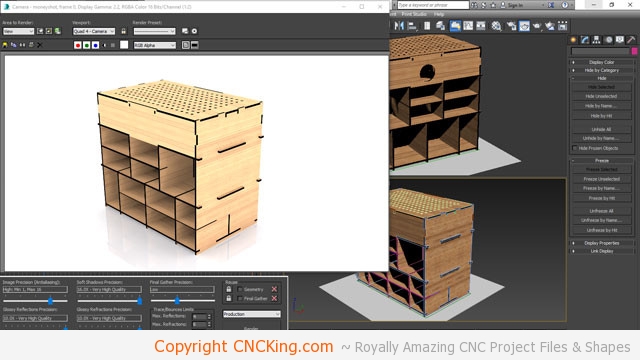

I increased the height, width and length of all the boards to take advantage of the maximum bed size my industrial wide-format Austrian CNC laser. So the panels are all roughly 60 cm wide by almost a meter high. As this is going to be used as a downdraft table, I don’t want it at eye level as I want to be able to use my weight to easily sand the pieces down so it has to be a bit lower.

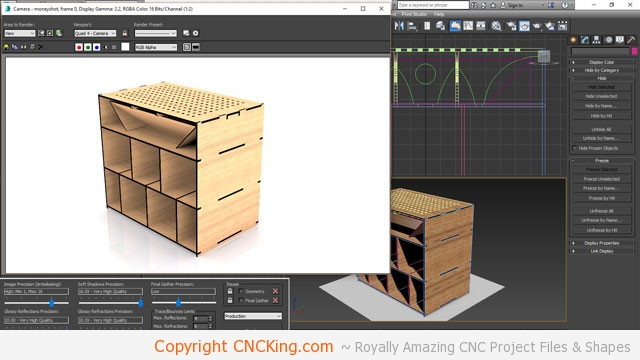

The top surface of the custom downdraft table has been modified to suit the new wider and longer structure, the next step is modifying the internal supports that will support the table on the inside where extraction will occur along with vertical slides. After the half inch structure is developed, it will be time to integrate the thinner 1/4 inch (6 mm) MDF slots throughtout the table and possibly some internal drawers as well to hold all the items this custom downdraft table will support.

I’ve now added internal supports that slot in both ways, this makes the overall structure stronger and as I’m using thick half inch (12 mm) MDF, when combined with glue, this table will be able to take the vibrations and stresses put upon it by the sanding and manual routing processes occuring on it. The other advantage of MDF over plywood is that it holds-up better to vibrations, this means the tools held within this custom downdraft table won’t be vibrating due to the dampening effect, which should help with tool longevity.

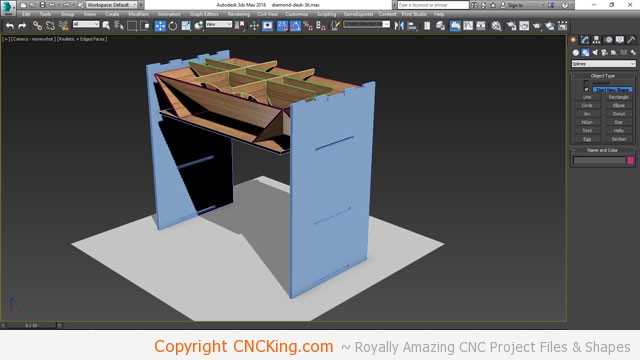

The top is now complete, the angled pieces of wood inside the draft table aren’t really needed as I can caulk the inside perimeter so there is no suction leakage from the sides – with only the suction being forced through the top of the table holes.

I don’t really care if I have a complete seal in the top by the way, there is a lot of dust being made on this table so any stray dust will be sucked-in one way or another. I just don’t want it to come from the bottom, only the top and sides.

As this table will be easily turnable, I want one side to have small shelves while the other side “whole” for larger items. This provides me with an opportunity to add more re-enforcing cross members, sliding from one side of the table to the next to both support the shelves and further lock the entire structure in place. Up to this point, everything is 12 mm (1/2 inch) thick, the shelves will be half that.

I’ve now done the middle part, I do have a large polisher so I left one big empty spot so that it can be easily put into that cubicle.

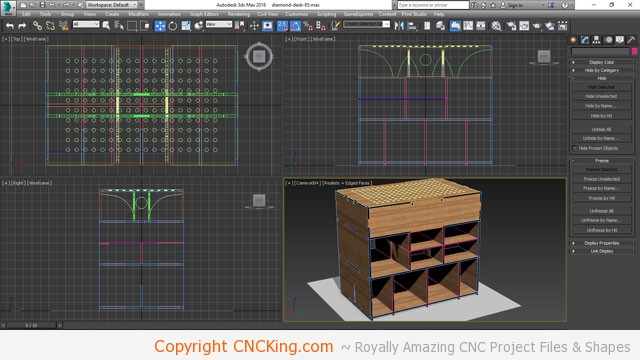

Like I did with the CNC laser station earlier, there is an opportunity on the sides to create an additional storage area for other items. For instance, I always have “scrap” sand paper that is still good but not good enough for production. Those should be on the side for easy quick access while the good stuff is safely stored inside.

There is one slight issue though, my boards are already at their maximum length to be laser cut in one pass, I do have a very little wiggle room though so I made the best of it and will use it to my advantage.

I’ve also added the exhaust hole centered in the back, this is where the hose will be inserted, as the caulking will be all around the inside perimeter, it doesn’t really matter if the box is a box or not, the suction will be evenly distributed. I’ll update the hole to the right size once I have decided what diameter I’ll be using in the shop. Thsi is meant to be easily taken out – by not having the unit INSIDE the table, it means I can continue to use the same exhaust system across the shop. ROI is optimal use of equipment too!

The other sanding and grinding tools will fit in the cubicles below but I will divide the two smaller ones up for additional storage. Like the middle layer, I’ve divided some of them up for additional storage options but these only go half way so I have a whole row of large cubicles for tools as needed.

More in a future blog post!