Roman Soldier Knife Holder: Design Process

I wanted to make a unique kitchen knife holder but didn’t like what I was seeing at the store, there was one that caught my eye of a roman soldier holding-up his shield with knives going through it. It was simple and not very detailed so I decided I can do a better job at it at a fraction of the cost (having your own CNC machines has its benefits). Let’s see how I built it here on CNCKing.com!

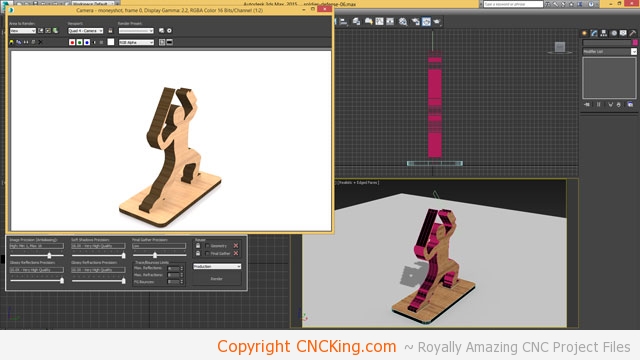

I decided that this model should be under 20cm high with a width of about half that so I made my placemaker meshes so I know what tolerances I’m playing with during the design process.

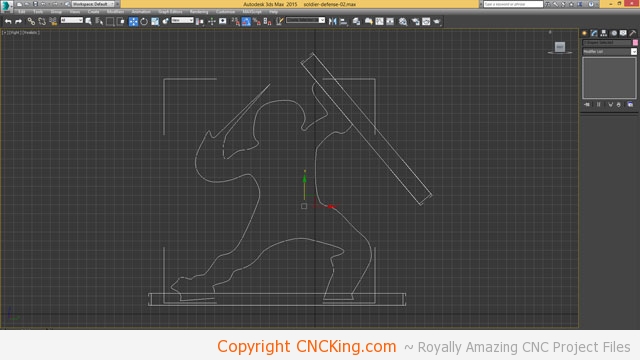

I’ve made a very rough outline of the position I want my soldier to have, I want him facing-up towards danger, not standing back from it hence the stance I’ve established. The shield will have to be one layer but the body of the character can be a few to add more strength to the model holding the knives.

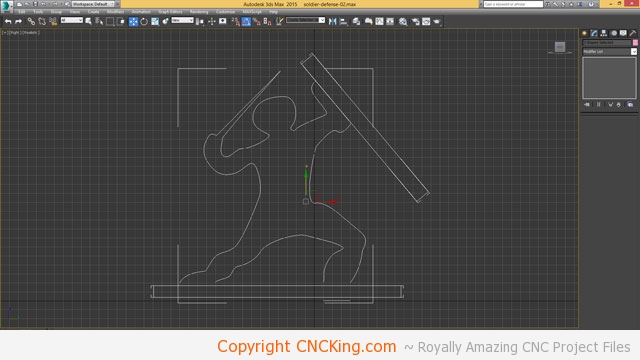

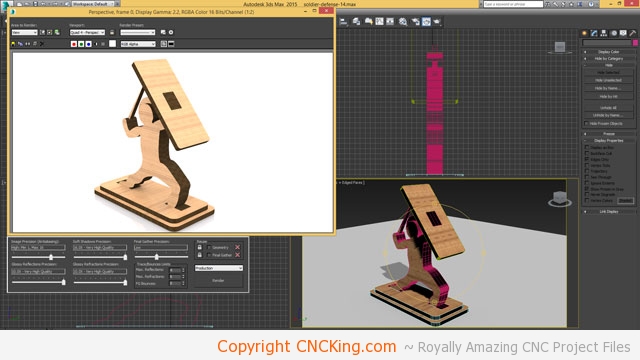

I’ve further refined the character and established the straight slots for the feet that will end-up going into the bottom plate. I’ll now play around with the shield position

The shield is now in the right position and the silhouette of the soldier has been further refined. I’m now going to start adding some depth to this model by extruding this 2D spline and creating a 3D out of this 2D line.

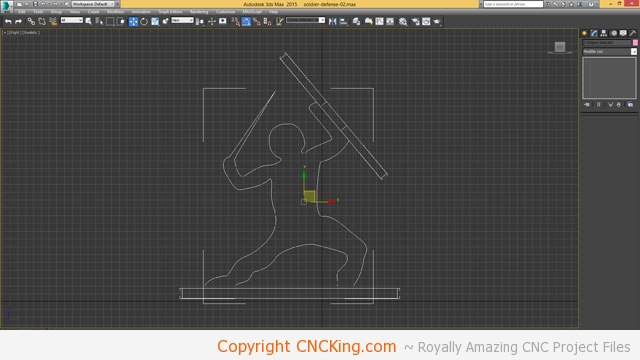

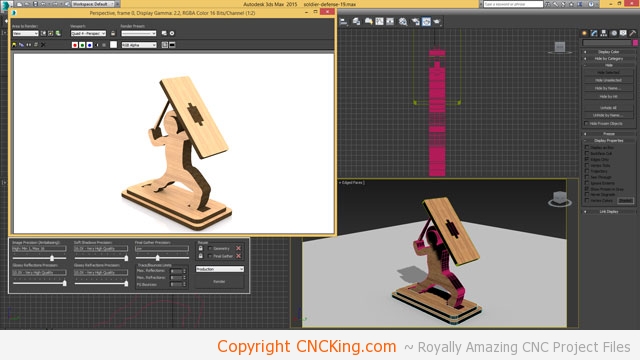

The render is looking good, the model has the thickness required for both presence and strength, I’ll now refine the two side pieces and work on the shield.I think this model will look fine being made out of 5 pieces but I want to make the pedestal doubled-up for more weight.

I like how the model has come together, I feel like it’s missing something though. I will add the holes for the knives later aftedr everything is cut as I still don’t know which knives will go where, regardless it will look cool!

It’s time to produce the 3D animation to make sure I didn’t miss anything followed by the cutting files so I can make this with my Austrian Trotec Speedy 400 flexx CNC laser.