Paul Mason, owner of Millennium Laser Systems (UK)

I’ve been designing things for CNC lasers for six years now but a lot of the fundamentals about the technology behind them, the source, the tube… I knew next to nothing about. I approached Paul, who has a has a PhD in Laser Physics and is the the founder of Millennium Laser Systems to see if he could answer my questions in plain English and he thankfully agreed!

You can visit Millennium Laser Systems at http://millenniumlasers.co.uk

Can you explain to me what the difference is between a CO2 and a YAG laser is and why they have such vastly different effects on the material they are engraving/cutting? You’d think energy is energy regardless of source.

ALL LASERS EMIT DIFFERENT WAVELENGTHS (COLOUR) OF LIGHT. ALL MATERIALS ABSORB DIFFERENT COLOURS OF LIGHT AT DIFFERENT RATES. SO IT IS ‘SIMPLY’ A MATTER OF WHICH WAVELENGTH IS ABSORBED BY THE MATERIAL BEST.

ALL LASERS EMIT DIFFERENT WAVELENGTHS (COLOUR) OF LIGHT. ALL MATERIALS ABSORB DIFFERENT COLOURS OF LIGHT AT DIFFERENT RATES. SO IT IS ‘SIMPLY’ A MATTER OF WHICH WAVELENGTH IS ABSORBED BY THE MATERIAL BEST.

ENERGY IS ONLY REALLY A FACTOR WITH THE LASER IF THE MATERIAL CAN ABSORB THAT COLOUR. SO BASICALLY HIGH ENERGY AND HIGH ABSORPTION GETS MORE WORK DONE IN A MATERIAL PROCESSING SENSE. THERE ARE OTHER KEY FACTORS TOO SUCH AS THERMAL CONDUCTIVITY AND NON-LINEAR INDEX OF THE MATERIAL WHICH PLAY VITAL ROLES APPLICATION.

A laser tube holds gas that reacts with electricity to generate power. How much of the power output (watts) is defined by the density of the gas relative to the type of gas found in the tube? Are these gases difficult to source and can you mix and match to affect output quality?

THE CO2 LASER IS A MOLECULAR GAS LASER, A YAG IS A CRYSTAL LASER. THE GASES INSIDE ARE NUMEROUS, OFTEN PROPRIETARY AND EACH PLAYING KEY ROLES. THERE IS SCOPE FOR VARYING GAS PARAMETERS BUT IT IS NOT A CARTE BLANCHE FOR SUCCESS. OFTEN AND FROM EXPERIENCE, MANY THOUSANDS OF HOURS ARE INVESTED IN PERFECTING THESE SYSTEMS

THE CO2 LASER IS A MOLECULAR GAS LASER, A YAG IS A CRYSTAL LASER. THE GASES INSIDE ARE NUMEROUS, OFTEN PROPRIETARY AND EACH PLAYING KEY ROLES. THERE IS SCOPE FOR VARYING GAS PARAMETERS BUT IT IS NOT A CARTE BLANCHE FOR SUCCESS. OFTEN AND FROM EXPERIENCE, MANY THOUSANDS OF HOURS ARE INVESTED IN PERFECTING THESE SYSTEMS

One thing that’s been bugging me for a while is why do some laser tubes cost hundreds of dollars while other cost thousands for the same output? How much of the cost is based off the gas relative to the casing holding it? Are there any other factors that have a bearing on gas tube costs?

SEE POINT#2. TODAY AND OFTEN THE MAIN DIFFERENCE IN PRICE IS DOWN TO WESTERN V. ASIAN MANUFACTURE. WEST OBVIOUSLY HAS HIGHER COST BASE BUT ALSO EVERY PART IS MORE EXPENSIVE WITH A GENUINE HIGHER SPECIFICATION. IT ALL ADDS UP.

THE COST OF SOME OF THE REPROCESSING SYSTEM CAN BE EXPENSIVE IF YOUR DOING IT RIGHT. GENERALLY A WESTERN TUBE MAY BE 5 TIMES FOR EXPENSIVE THAN A CHINESE TUBE BUT WILL LAST LAST 10-30 TIMES LONGER. YOU GET WHAT YOU PAY FOR.

What are your views on ceramic tubes compared to metal and glass ones? Trotec Laser came out with Ceramicore recently that promises increased efficiency and more stable power output. They have no weld joints as well, so gas leakage is no longer an issue.

GAS LEAKAGE IS ALWAYS AN ISSUE. COMPANIES HAVE BEEN USING CERAMIC CAVITIES FOR A LONG TIME, WAY BEFORE METAL CAVITIES IN-FACT. SOME BIG BRANDS STILL DO. IT COMES DOWN MORE TO THE RESONATOR DESIGN AND POWER LEVEL DESIRED TO DETERMINE THE BEST WAY FORWARD.

GAS LEAKAGE IS ALWAYS AN ISSUE. COMPANIES HAVE BEEN USING CERAMIC CAVITIES FOR A LONG TIME, WAY BEFORE METAL CAVITIES IN-FACT. SOME BIG BRANDS STILL DO. IT COMES DOWN MORE TO THE RESONATOR DESIGN AND POWER LEVEL DESIRED TO DETERMINE THE BEST WAY FORWARD.

THERE IS NO GOLDEN RULE. ALL SEALED CO2 LASERS MUST HAVE SEALS SOMEWHERE AND THERE IS LOT OF VARIATION IN SEALING METHODS SUCH AS METAL, RUBBER, GLUE…….SYNRAD USE RUBBER AND CAN ACHIEVE 20 YEARS SEALED LIFE SO ANY CONCLUSION COULD BE DRAWN. MILLENNIUM USES ITS OWN PROPRIETARY METHODS FOR SEALING FROM METAL, GLUE AND OTHERS

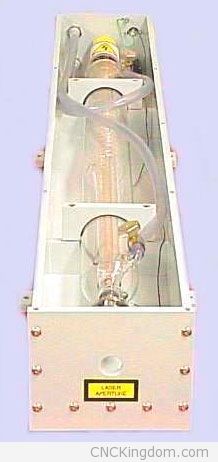

Millennium Lasers Ltd. is now offering 400W and 600W tubes, what are some of the challenges present with tubes as you go higher-up the wattage charts? What is the major limiting factor that you must face when designing laser tubes and how are they overcome?

INCREASING POWER FROM A SEALED SYSTEM IS NOT EASY. THERE ARE MANY CHALLENGES AND THESE DIFFER WHETHER YOU USE RF OR DC POWER TECHNOLOGY AND ALSO DEPENDING ON THE MATERIALS USED FOR THE RESONATOR STRUCTURE.

INCREASING POWER FROM A SEALED SYSTEM IS NOT EASY. THERE ARE MANY CHALLENGES AND THESE DIFFER WHETHER YOU USE RF OR DC POWER TECHNOLOGY AND ALSO DEPENDING ON THE MATERIALS USED FOR THE RESONATOR STRUCTURE.

THE MILLENNIUM DESIGN IS UNDER DEVELOPMENT AND IS OUR 3RD ‘MANIFESTATION’ AND OFFERS THE POTENTIAL FOR THE LOWEST COST, HIGHEST RELIABILITY SYSTEM YOU CAN THINK OF.

IT A LITTLE ‘LEFT-FIELD’. HOPEFULLY LAUNCHED SUMMER 2014.

Your company does extensive consulting for some of the biggest CNC laser manufacturers in the world, what are some of the developments that will be coming out in the next few years in the industry that you can share with us?

THAT’S A TOUGH ONE. I TEND TO ADVISE AND STEER ON THAT TOPIC RATHER THAN TRYING TO INNOVATE. THE USERS KNOW THEIR GAME FAR BETTER THAN I SO I SIMPLY FOLLOW THEIR LEAD AND HELP TO MAKE IT BETTER -THEY KNOW WHAT THEY WANT AND I SIMPLY FACILITATE THAT FOR THEM

THAT’S A TOUGH ONE. I TEND TO ADVISE AND STEER ON THAT TOPIC RATHER THAN TRYING TO INNOVATE. THE USERS KNOW THEIR GAME FAR BETTER THAN I SO I SIMPLY FOLLOW THEIR LEAD AND HELP TO MAKE IT BETTER -THEY KNOW WHAT THEY WANT AND I SIMPLY FACILITATE THAT FOR THEM

THE BIGGEST IN-HOUSE INNOVATION I CAN THINK OF FOR THE EVER-GROWING CNC MARKET IS THE HIGHER POWER MILLENNIUM CO2 SYSTEM WHICH SHOULD BE IDEAL FOR METAL MARKING AND CUTTING OF THIN STEELS WITH ECONOMICALLY PITCHED PRICES STARTING AT AROUND £25,000

Why do tubes eventually wear-out? If the gas doesn’t leak from the tube, then nothing is lost or gained inside the tube so it should be able to run indefinitely no?

EVERYTHING LEAKS, ITS ALL ABOUT THE RATE OF LEAK. GASES ‘LEAK’ OUT OF THE LASER ENVIRONMENT AND GASES LEAK INTO THE LASER. THIS ALL KILLS THE IONISATION PROCESS INSIDE THE LASER CAVITY.

THERE ARE MANY OTHER FACTORS WHICH ARE PROPRIETARY KNOWLEDGE TOO. THE GAS DEGRADES WITH LIFE AND THE BREAK-UP OF CO2 IN A NON-RECOVERABLE WAY IF NOT MANAGED PROPERLY. ITS ALL ABOUT MANAGEMENT OF WHAT YOU KNOW IS HAPPENING.

Anything else you’d like to add?

ONLY THAT I AM REGULARLY CONTACTED BY PEOPLE THAT HAVE PURCHASED A LOW COST CUTTER OR LASER TUBE FROM CHINA OR A WESTERN ‘BADGED’ ITEM THAT BREAKS DOWN ALL TOO QUICKLY.

THEY THEY CANNOT AFFORD THE PRICE TO REPAIR OR BUY A NEW ONE. SO AT THE END OF THE DAY THEY LOSE EVERYTHING INVESTED IN THAT PROJECT. DON’T BUY TOO CHEAP EXPECTING BMW QUALITY.

ASK WHERE DOES THE M/C COME FROM AND ALSO THE LASER TUBE AND POWER SUPPLY. A REPUTABLE US M/C SUPPLIER WITH A GOOD CNC SYSTEM MAY BE USING A LOW COST CHINESE LASER TUBE WITH 2000 HOURS LIFE AND POOR BEAM QUALITY AND SO ON.