Massive Time Savings from CNC Tiling

Ever since I’ve discovered tiling and became proficient with it with my ShopBot Desktop from ShopBot Tools Inc. (shopbottools.com), my world has literally changed for the better.

Where previously I’d screw-in one 400 x 500 mm sheet of 6mm plywood, cut it out then unscrew to put another one in… I now just use one 1200 mm x 600 mm sheet and save a ton of time!

Stronger sheets, less screws!

I’ve discovered something… when you use a larger sheet, things tend to not move around nearly as much as smaller ones – it’s weird but I usually put in only 2-3 screws when I cut vs the 10+ I use to have to use for my CNC routing. This makes no sense but it works like magic! I think just having the extra 3x weight of the board on the sacrificial surface keeps things from moving and the larger sheet is just harder to move around than the smaller one. This is a dramatic change in time savings for me as each screw I have to put into the board, must also be screwed out! 2-3 screws is far more efficient than 10+ and keep in mind, I don’t have a vacuum system!

Quicker sheet conversions!

What’s quicker, cutting down a full-sheet of plywood into 4 or cutting it into 12? Of cours 4! So now only do I get away using far less screws but I also don’t have a pile of small boards to cut to size nor do I have to spend time putting one on the work platform at a time. Tiling is just so wonderful that I use it now even when I don’t need to! Moving a sheet down for the next tile is just so much faster than my old way of doing things!

Precision loss

I’ll be the first to admit that you do lose some precision using tiling with a CNC table router, there are ways around it of course but I can’t be bothered, I’m young, my eyes still work… so I just use them to judge distance. I know this will change but it only affects pieces that go across three tiles as a few mm off here or there in either X or Y axis isn’t a big deal for me. The wonders of being your own customer! The fact is that most of my parts done need tiling at all so in reality, I don’t lose any precision in the cuts that I do. I have considered moving to larger sheets so having a tile that’s 2 400 x 600 mm instead of just 1200 x 600 but I have noticed that because I don’t have supports at either end of my ShopBot, there is a bowing going on the platform as each edge hangs that would just get worse and the savings are minimal at best. I think 1 200 x 600 mm is just the perfect size for the projects I make.

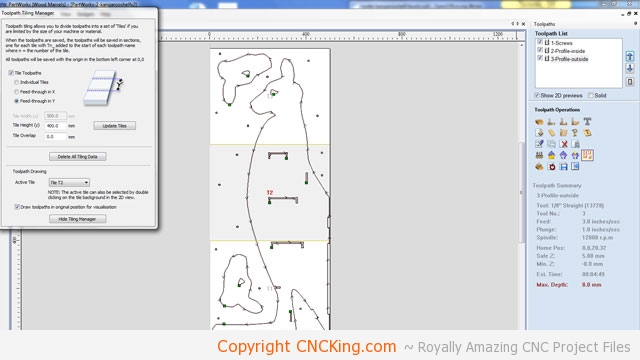

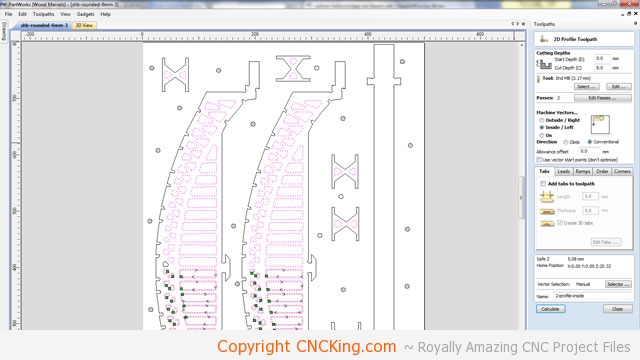

CNC machine tiling

I’ve seen variations of CNC tiling used for lasers and plasma cutters – it’s just such a great way to augment the maximum build part size of your projects but it does have a limit, either your X axis or Y axis as the gantry needs to move overhead somehow and can’t go through your board.

https://vimeo.com/208172270

Buy smaller and tile to profits?

Tiling is a great way to augment your part size, you do lose some precision but it isn’t a way to get away using smaller platform to increase ROI over a larger machine. Why? First off is the loss of precision but more importantly, you are stopping the machine and having to reset everything for each tile… this is a waste of time as if you had a full-sheet machine, you just press “cut” and the entire projects is done without your intervention.

Think of it this way, you can buy a photocopier to print your published book or you can send it to a print shop… whether you make 10 copies or 100 copies, the amount of work is the same for the print shop, they just leave the printer running for a few extra minutes but for your photocopier, you need to spend time filling it with paper, placing each sheet one a time, the quality will suffer and you’ll constantly run out of ink mid-way through a published book. The print shop will be able to make your book professionally far faster and more efficient than you because they have a big machine that requires minimal intervention which you and your photocopier just need to much work to get a finished product.

Tiling is awesome!

Again, it’s just hard to describe how awesome tiling really is until you get a full-sheet CNC machine, which is something I’m looking at getting sometime next year. It’s a wonderful stop-gap but not a replacement due to the compromises needed and extra time involved. Having powerful software that can enable this is great too – something to check for sure when you are in the market for a CNC that there is an easy and ACCURATE way to accomplish this.

Get a full-sheet CNC machine

If you are in the market for a CNC plasma, table router or laser cutter – seriously… and I mean SERIOUSLY… consider spending more money just to have full-sheet capabilities. The less time you spend cutting boards down to size, resetting designs and moving board around the more efficient your CNC operation will be and the more profits you will be able to generate with in a given hour doing far less work.