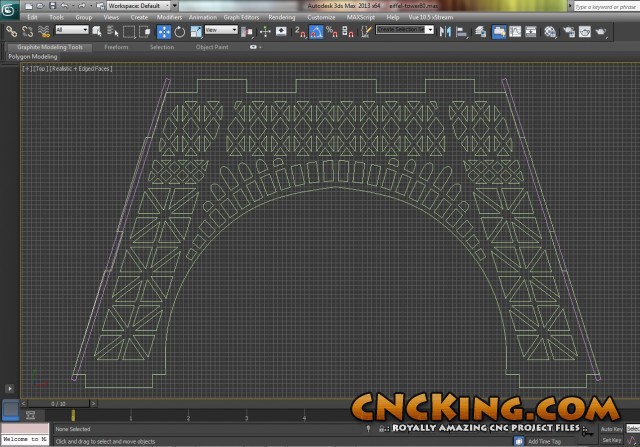

Laser Cut Eiffel Tower: Design Update 3 – Absolute Symmetry

If there was ONE thing any new designer to CAD based design should master, it would be that of absolute symmetry. I’m not talking about “close enough”, I’m talking about dead-on precise symmetry in your designs. To give you an idea of scale in the picture below, each square you see in the pictures is 4mm square.

If it wasn’t for those little rectangles on both sides measuring exactly 4mm in thickness and rotated 17.5 degrees, you’d swear that this object was 100% symmetrical (click the image to see a larger representation). I know… I did with my last Eiffel Tower design update a week ago. This is something that sneaks-up on you when you least suspect it and the only reason I noticed was that I was having alignment issues when it came to putting four of these together supporting one another. Something was always a little off and right away, I knew my design wasn’t symmetrical. If my design was made in any other way, I never would have noticed!

The margin of error you see in the above that’s causing the asymmetry is a fraction of a mm… yes, we are talking about – incredibly small to not be noticeable – design error here but it’s vital that this be solve NOW. Why? Well, if you think of the Eiffel Tower, it’s really nothing but a static iron tree, where the roots is what holds everything in place. If this vital part is off-kilter (the base), all the design modifications required to adapt the design above it will cause increasing levels of error. Sure, this is a fraction of a mm but by the time I’d get to the top, that fraction could become a few mm.

When I design things, they better damn well go together because lets face it, your CNC machine is precise to a fraction of a mm but the material you use is rarely this precise. The 6mm thick plywood I buy is RARELY 6mm thick – I know – I check it with digital calipers not a manual ruler! That 0.2 —> 0.6 mm difference in material thickness again, doesn’t sound like much but throw-in an adapted design that’s based on a flaw and as you see, these fractions add-up very fast.

You ever wondered why some designs aren’t solid, fall apart or become wobbly over time? THIS LACK OF ATTENTION TO DETAIL IS WHY!

Moral of the story, CAD software is a must to make good quality and long-lasting designs. Sure, you can free-hand things, lots of designs on CNCKing.com are done just that way by other designers with far more patience and skill than myself… and I’m astonished that they work so well but at the end of the day, I don’t want my designs to be good, I want them to be MARVELS – hence why the original name of my company use to be WoodMarvels.com!

If you noticed, I haven’t posted a design update for this model in over a week and a half – one of the joys of working on other people’s designs is finding time to work on your own!