Jean Le Bouthillier of Boots Industries (Canada)

Kickstarter is starting to load-up with a lot of different types and styles of 3D printers… I’ve featured quite a few here on CNCKingdom.com but sometimes people come-out with something that has a unique design twist or offers a great “new” capability and the BI V2.0 is one of them featuring a huge build volume! What I especially like is the round heated bed, it just looks cool!

Jean Le Bouthillier is the founder of Boots Industries which you can visit online at http://bootsindustries.com and I hope this interview gains additional insight about the process behind 3D printing manufacturing.

You can visit their campaign here: http://www.kickstarter.com/projects/1784037324/bi-v20-a-self-replicating-high-precision-3d-printe

Where did your interest in 3D printers come from and what made you want to pursuit it full-time by opening Boots Industries?

We started using 3D printers about 15 months ago when we purchased our first 3D printer kit. We used it to create prototype parts for other projects. We were amazed at how quickly we could iterate between parts revisions and make the project move forward faster than was previously possible.

The 3D printer kit we were using cost more than 2000$ and took a long time to assemble. It was not user friendly and the learning curve was quite steep. So we decided to develop a sub 1000$ 3D printer that would be mainly sold assembled. The result was the founding of Boots Industries and our first offering: the Rostock BI V1.0.

We quickly sold the V1.0 and this success along with positive feedback from the community encouraged us to develop the BI V2.0 which offers way more for the same price point.

Boots Industries created the Rostock 3D printer and decided to go with Kickstarter with your newest model the BI V2.0? Why Kickstarter and how has the response been marketing wise for your entire company in general?

The BI V2.0 being our second 3D printer, we’ve already learned what it takes to deliver a production ready 3D printer. We wanted to use Kickstarter to capture the attention of the public and tell the story of our company and what we are doing.

I think that the response has been amazing as we have received positive comments and praise about the design from all over the word. Our campaign quickly reached its minimum funding goal and we are now focused on reaching our stretch goals to offer even more to our backers.

How does your 3D printer compare to others in the market, notably the MakerBot Replicator and the 3D Systems Cube other than a far larger print area?

The MakerBot Replicator and 3D Systems Cube are great printers, built by companies that have substantial financial backing. Notably Makerbot by Stratasys and 3D Systems being a publicly traded company. Their printers are manufactured in an industrial setting with custom metal parts, injection molded parts and other high end and customized parts. The price point of these printers exceeds 2500$ and their design is closed-source.

At Boots Industries, we also offer a great product, but we aim to keep the cost below 1000$ and use components that are commercially accessible by everyone. Another aspect of the BI V2.0 is that we’ve made the design open source and self-replicating. These features will allow the community to manufacture, repair and modify their own 3D printers. We want to empower people.

Your Kickstarter campaign features a 3D printers that seems far more minimalist than your previous two models, what was thinking behind this design decision and what were the benefits?

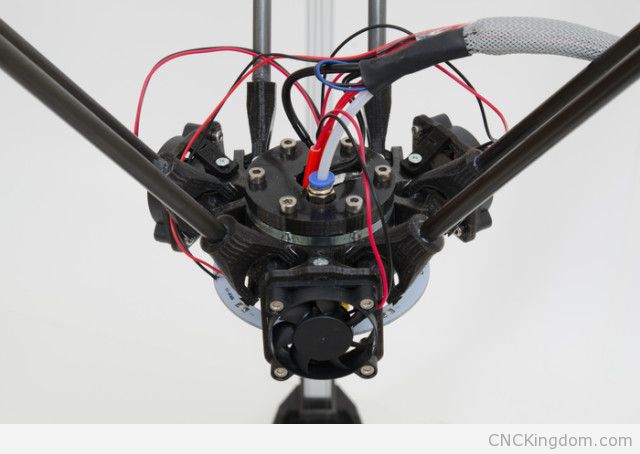

We wanted to design a printer that had a very sturdy and precise frame while at the same time being self-replicating. We also felt that by using a minimalistic frame, the printer’s focal point (from any direction) would become the delta manipulator and the 3D part being printed. This was a difficult challenge, but the end result is a perfect mix between form and fashion. We find beauty in minimalistic designs that accomplish the task.

You’ve already reached your goal of acquiring 30K from Kickstarters… what do you think lead to your success while others have had so much trouble achieving their funding goal?

I think that we’ve been most honest about our offering, our skills and people can see that we are truly passionate about bringing an affordable option to the table. We’re definitely not taking huge margins on these 3D printers and we are making the result of our development work accessible to everyone.

I think that Kickstarter can best be described as “democratic funding” in that people get a chance to back projects in which they believe. We’re here because we have a passion and people can see that.

You not only sell fully configured machines but hardware components as well – how much of your clients prefer the self-build vs already built approach?

We definitely didn’t want to throw a simple box of components at the user, but we needed to find a way to ship such a large unit without breaking the bank. As such, the main reason for separating the towers is to dramatically reduce the shipping footprint. We’re taking care of the longest and trickiest operations (i.e. stringing the towers, electrical wiring, etc).

The result is a simple to assemble printer once you receive it with steps that are mainly mechanical in nature (i.e. assembling the frame and connecting wires).

Unlike all the other 3D printers on the market, your bed is round – that’s pretty neat! Why did you go with a heated bed vs using special adhesive glue to keep the model on the platform during the build process?

The round bed is a result of the delta geometry which creates a circular footprint. We are using a heated bed, because the heat keeps the parts at the “heat deflection point” which is the point at which the parts become malleable. This dramatically reduces instances of warping, but we also use hairspray (believe it or not) to help the parts stick to the glass surface.

I think that we have seen a lot of printers moving away from this feature, because they can lower the cost per unit by offering lower power supplies and remove the heating components. We consider it to be a must have, especially if you are printing anything else than PLA (and PLA still warps).

Anything else you’d like to add?

Were always looking for talented individuals who would like to work with us or share their ideas! If you have comments for us please contact us at [email protected]. Consider backing our project! Merry Christmas and Happy New Year to all!

You can visit their campaign here: http://www.kickstarter.com/projects/1784037324/bi-v20-a-self-replicating-high-precision-3d-printe

Boots Industries

Announcesthe Launch of The First‐Of‐Its‐Kind Self‐replicating, High precision 3DPrinter ‘The BI V2.0’

The BI V2.0, a delta style 3D printer featuring widely available and self‐replicating 3D printed components has been launched by Boots Industries. The company has launched a Kickstarter campaign to roll out this new 3D printer with its sturdy self‐replicating frame that offers one of the largest 3D build volumes and outstanding print quality to the public.

Quebec, Qc, Canada (PRWEB) December 20, 2013

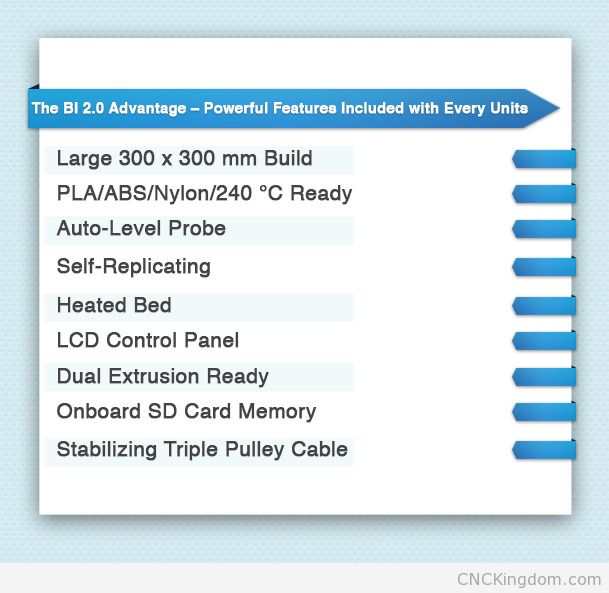

With its reinforced frame and triple pulley system, Boots Industries BI V2.0 is built to offer a true 300 mm by 300 mm (diameter by height) build volume and features a self‐replicating design that is all set to empower the public to print their own 3D printers.

Made of steel reinforced 3D printed corners and 3/4 inch anodized aluminium extrusions that act as structural and linear motion components, the BI V2.0’s has a clean, practical, and dual‐purpose design. Its design can support up to triple extrusion and print virtually any 1.75 mm filament extruding at up to 240 degrees Celsius (PLA/ABS/Nylon/+).

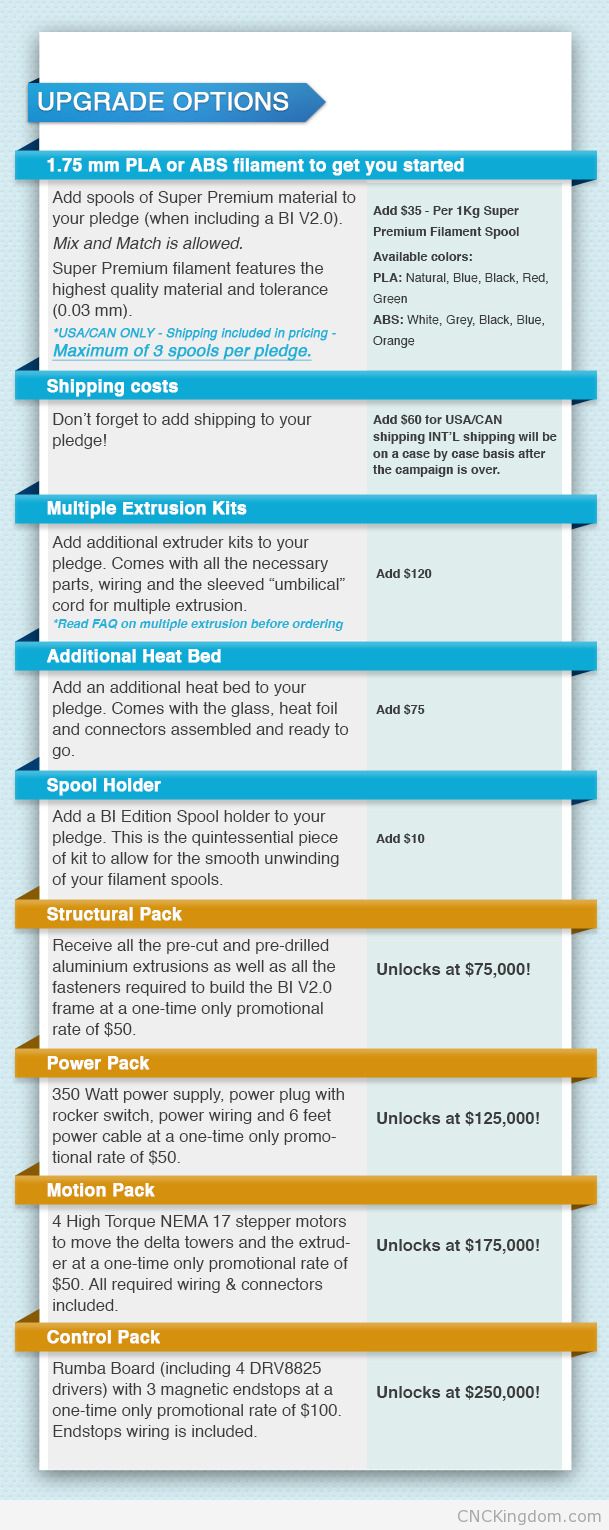

Although the BI V2.0 is definitely ready for production, Boots Industries plans to offer it for $799 after their Kickstarter campaign that is geared towards acquiring the components in bulk, fine tuning the kits for packaging, and working with specialized local providers to explore new ways of product packaging that result in the lowest footprint and the highest safety during shipping. Kickstarter printers will be the first to ship even before they add the BI V2.0 to their online store.

Speaking about the successful concept development and creation of the BI V2.0, Jean Le Bouthillier said, “This version represents the evolution of our work and reinforces our core belief that with the right components and a little bit of ingenuity, there are no limits to creating a high precision, large build volume 3D printer at a relatively low cost. Our assembled components remove the longest and trickiest steps from the equation. With our simple to follow instructions, the partial assembly will conservatively take between 30 minutes and an hour.”

The BI V2.0’s triple pulley system, which automatically keeps the delta arms of each tower level, allows for a large build volume and high quality 3D printed pieces. The result is a high precision motion accomplished with low cost and widely available components. High‐poweredNEMA 17motors with 32x Microstepping ensuremaximum precision using 3Dprinted linear bearings during vertical displacement ofthe delta towers. The 3D printer also features a non‐stretch, 50 lb test spectra line that will never stretch during accelerations prompted by print requests.

The BI V2.0 can be controlled through the use of a conveniently positioned LCD controller with a large screen that features all the key functionalities such as moving the printer head, setting speeds and temperatures, and starting prints from a 4 GB SD card that comes standard with the LCD controller. All the 3D printers will also ship with standard features, including a heat bed featuring a triple point adjustment mechanism to make macro adjustments and an auto‐level probe that ensures consistent layering across the entire 300 mm diameter.

Describing the self‐replicating design, the most unique aspect of the BI V2.0, François Crête stated, “Developed using our innovative approach to offer the highest standards of print quality, the self‐replication feature enables you to use the BI V2.0 to print it’s own core components. The result is that anyone can improve upon, share components and build their own printer at a very low cost.”

Boots Industries will make all their 3D models open source by releasing the source files in the Sketchup format once their Kickstarter Campaign ends. They will also provide online videos, articles, a wiki, and dedicated support for all aspects of the BI V2.0. More information about the Kickstarter campaign and the powerful features of this one‐of‐a‐kind 3D printer are available at: http://www.kickstarter.com/projects/1784037324/bi‐v20‐a‐self‐replicating‐high‐precision‐3d‐printe

About Boots Industries:

Boots Industries was founded in 2012 by Jean Le Bouthillier, MSc and François Crête, BEng with a goal of making 3D printing more accessible by offering high quality at an affordable price. The company is already printing all the 3D printed components and they have the ability to scale production (by using more printers) to meet any demand.

One of the top Canadian suppliers of PLA and ABS filament who also offer other electrical components for 3D printing, the company has secured new contracts with electronics manufacturers to produce the electronics in bulk.