Boots Footwear Holder: Design Process #2

Time to keep on designing this Boots Footwear Holder here on CNCKing.com!

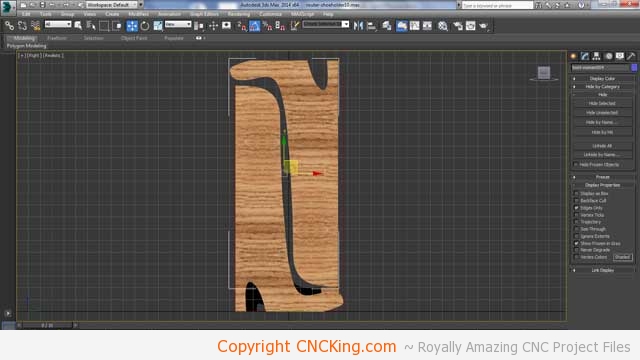

I want to be as efficient as I can cutting these pieces out and realized if I rotate the cowboy boots 180 degrees that both boots could be cut easily from one 120 cm x 60 cm board with room to spare. I tried this as well with the taller boots and I’m just a few cm off from being able to this with those as well so I’m going to bring their height down a bit – something that won’t be noticeable anyways – and be able to cut two on each board instead of one while wasting lots of room. The shelves are basically large rectangles so this allows me to have four complete boards with only boots and then another one or two just for shelving and their relative supports.

The difference may seem extremely minor but I’ve gained time by not having to cut out extra boards and money during the process. That’s called being a SMART and EFFICIENT designer… wished I was always this smart and efficient!

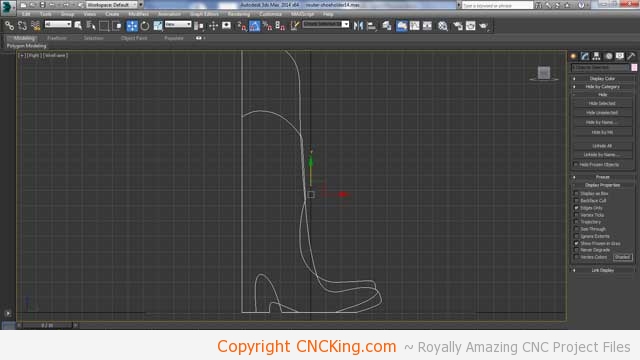

The boots are now set-up to be cut efficiently and the shelving spacing is now dead-on. The next step is to measure how “high” shoes and boots are in general and make the shelves fit within those vertical parameters. Looking good! My boots are slightly more than 60cm acros both boots, if I bring them in a bit more this will mean I can cut them horizontally instead of vertically – why is this important? Well, it means I wouldn’t have to tile them… I’d like to have one shelf go all the way through both sets of boots – it speeds-up the build process, dramatically decreases my piece count and makes everything stronger overall.

I’m not happy with the feet, in the back I think it’s fine having two different set-ups but for the front, it just looks bad. When you think about it, there is no reason why the other boot can’t be identical to the cowboy boot but with a high heel and longer top. This would fix the esthetics and mean I don’t need to double-up (four-up) the inside where the two boots meet. Besides, I prefer the curve of the cowboy boot over the overly straight woman’s boot but as it will be higher, there is no reason why I can’t make it extend a bit more towards the front as the curves would line-up.

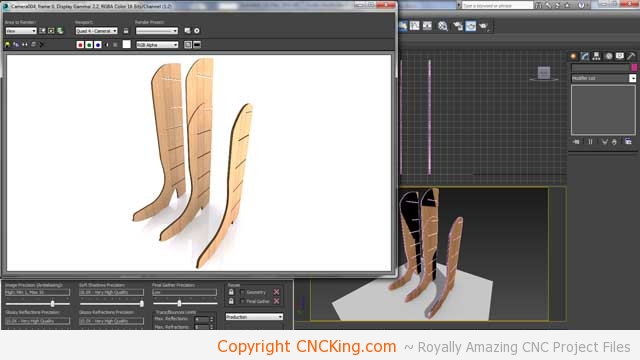

I really like this new set-up… there is a lot more symmetry across the board, I’m happy with the esthetics and measuring my shoes, I’d be fine making the shelves 5 cm high but as there is some variance, I’m going to go with 15.4 cm in between the shelves. This means at a height of roughly 120 cm I’ll have 5-7 shelves from top to bottom. If you need more room, you could easily double shoes up but I think 5 pairs of shoes is more than enough unless you have more than one pair of feet. I fear that if I left more room, it would be a motivation for my wife to fill it up with more footwear!

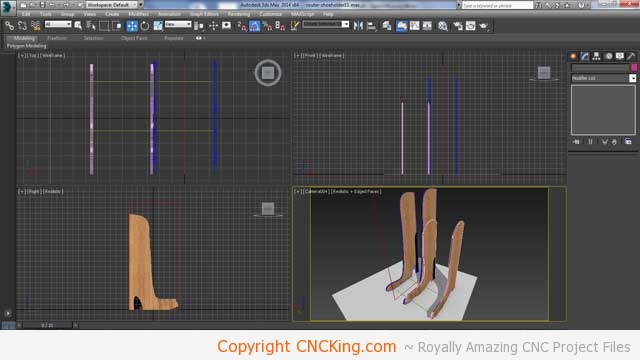

These are rough shelves to give me an idea of where to put my tabs. I don’t need crossmembers because I have plenty of vertical supports (boot silhouettes) and footwear isn’t the heaviest thing either.

I build my slots going up both boots and deleted my temporary shelves. Looking at the pieces, the decision to use the same base boot design was a good one.

Part 15 in a few days…