Wooden Big Wheels Tricycle: Part 5 ~ Creating the Cutting Files

It took about two weeks to get to this point, now it’s time to make the cutting files and tool pathing based off the model I created here on CNCKing.com.

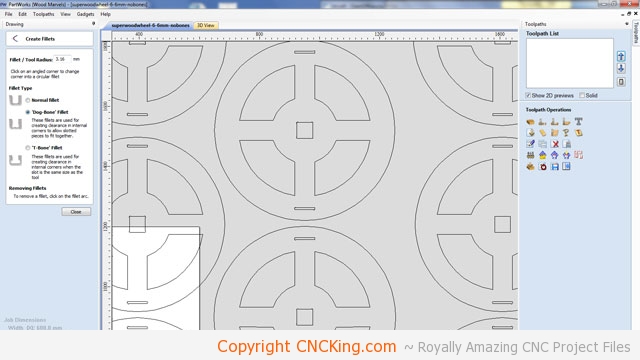

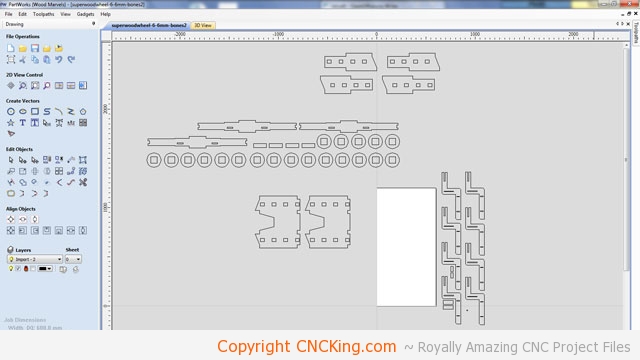

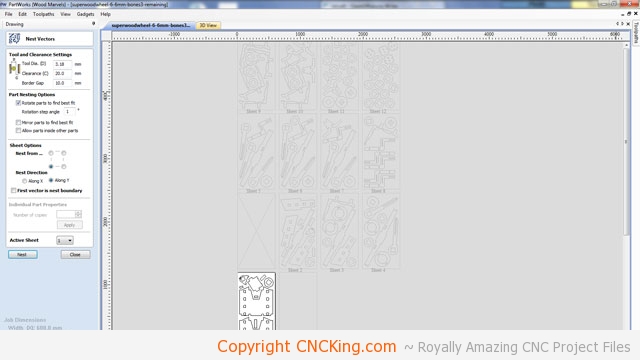

My wood is 6.5 mm and not 6 mm, I’ll scale the entire drawing up by 10% to make sure that everything fits properly. This model will be even bigger than I envisioned! After exporting the file from Adobe Illustrator and importing it into PartWorks, I then begin the tedious job of adding dog bones to all the inner pieces.

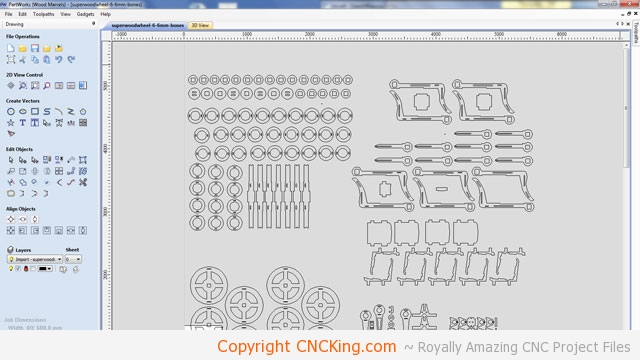

It took a little over an hour but I’ve now finished dog bonning all the parts that needed it. Next step up is sorting them all out by board but first I need to group all of the individual components in each piece to make sure nothing gets lost (inside parts) while I move them around and rotate things to fit.

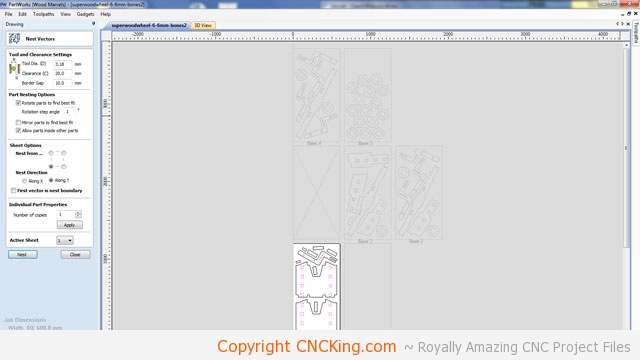

I watched a youtube video where somebody was table routing a project and I noticed he used automatic nesting… I didn’t even know this existed! I just about feel off my chair as I’ve been manually optimizing my sheets for two years! I set-up the parameters and 5 minutes later, the sheets are better optimized than I ever could have done in a fraction of the time! Wow… never too late to learn new tricks!!!

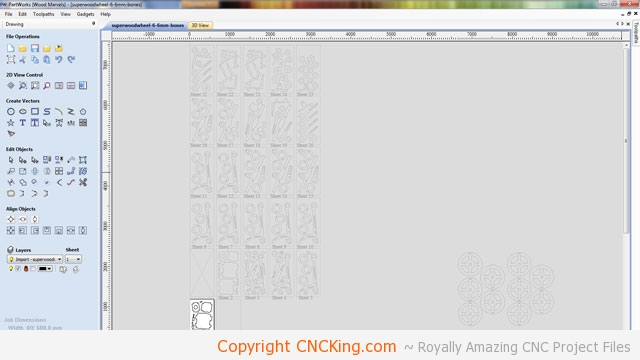

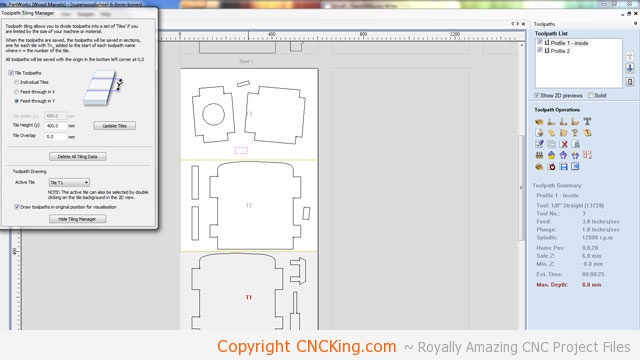

The only issue I have with the automatic tiling is that I need to further uptimize the placement of the parts as I want to cut them as whole as possible so it means repositioning smaller segements to fit onto one tile instead of across two. This has still saved me a tremendous amount of time, just doesn’t replace manually fixing and tool pathing that needed to be done anyways.

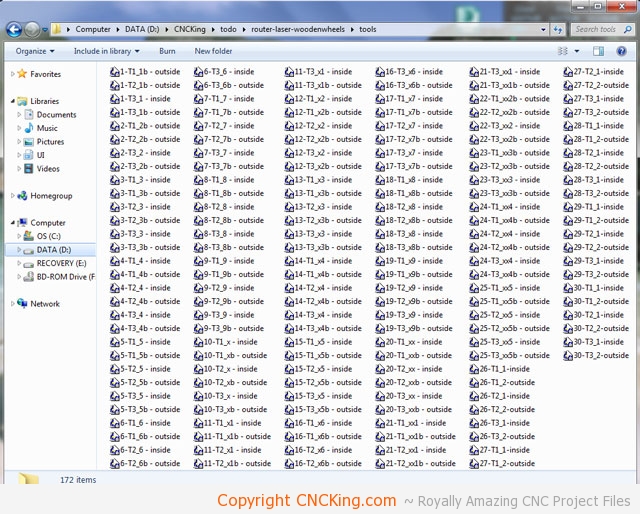

As you can imagine, it took a few hours to clean-up the toolpathing and the result is 172 individual cut files for this entire project as I have to do each 60 x 120 cm sheet in thirds to fit through my machine. This is easily a full day of just cutting… then it’s the fun task of organizing all these parts into assemblies and into the final model. If the scope of this isn’t big enough to warrant a full-sheet router then I don’t know what will convince people. I know for me, full-sheet router is a must if I have to cut this again!

Half way through the cutting process, I realized I was missing some parts, for some reason when I brought in files from Adobe Illustrator into PartWorks, it skipped the outer parts so what I did was create another cutting file containing those missing parts. This worked out for the best as I actually found a mistake in my model in the process – the lower floor for the seating wouldn’t be able to be made in the real world as you can’t enter tabs in two corners at the same time. This project just got even bigger!

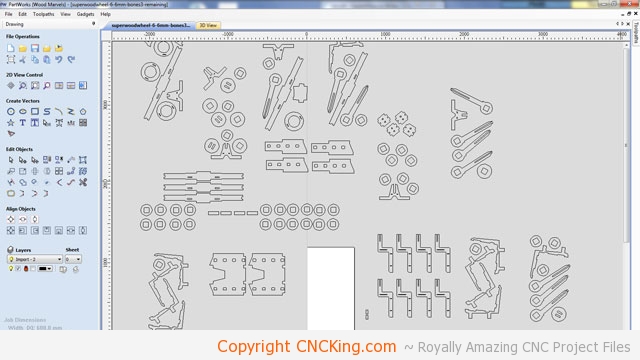

Now that I have a bit more experience with nesting and setting-up my parts – I realize that I could actually reduce orientation to 1 degree and fit a lot more parts per board as a result. In hindsight, I should have checked through to make sure all the pieces were in my original import rather than assuming and using 1 degree instead of 5 as I probably would have ended-up with the same board count overall with a lot less wastage. Revised board number is now 36! I thought I was half way through and apparently, I’m not even that far ahead!

I’ll do is bring-in all the remaining boards (I was up to #17 which I marked all with a pencil for easy reference) and mix them up with what I missed here into a third document which should optimize things further, it take a bit more time on the computer as I’ll have to re-do all the toolpathing but I save material and money as well as quite a few hours in the process.

As the part density is far higher now, I will have to put screw holes in all these boards while in most of the previous boards, I was able to skip this step and figure it out by eye which saved a lot of time. Win some hours and lose some hours. The total sheet count left to be done is 12 sheets, originally I would have had 5 (new) + 9 (remaining to be cut) so this exercise saved me three 60 x 120 cm sheets in total which is about an hour and a half of saved time which I will now spend remaking the toolpathing I made a while back on the original nesting. My boards are now fuller as well, which means lest wastage! I saved almost a full sheet at the end of the day which is 44$/sheet!