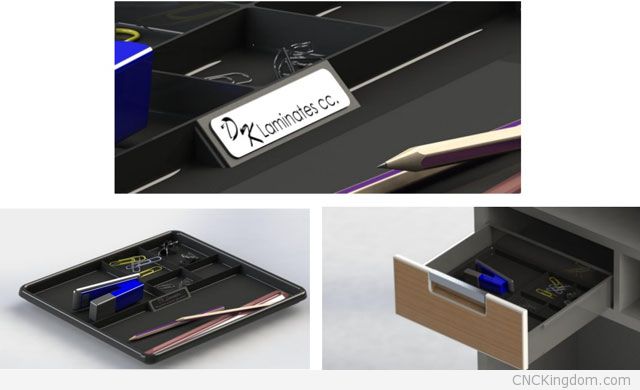

Werner Olivier, Industrial & Office Designer at DK Laminates (South Africa)

Industrial and office designer Werner Olivier has some great ideas along with some very impressive drawing skills that makes for an awesome combination. Key takeaways from this interview include:

- The best way to learn the program is to go into detail with your designs, make it exactly like it would be in real life.

- My job is to put design concepts into production…most of the time I have to make other designers ideas work in the factory.

- The university is not going to make you a designer, they only need to spread the word and if it really is your passion you will.

You can get a hold of Werner at http://www.coroflot.com/

Why did you want to get into industrial design and what aspect of it do you enjoy the most? What tools do you use to create your projects?

First I was interested in architecture, but the TUT didn’t accept my application so I thought that maybe I should wait another year and apply for architecture again. There was a course three dimensional design which I wanted to do for a year instead of doing nothing. Basically I started studying a course, and I had no idea what it was about this Industrial design thing.

First I was interested in architecture, but the TUT didn’t accept my application so I thought that maybe I should wait another year and apply for architecture again. There was a course three dimensional design which I wanted to do for a year instead of doing nothing. Basically I started studying a course, and I had no idea what it was about this Industrial design thing.

In the middle of the year, I realized that this is awesome, and never had a thought about architecture again.

The reason for my interest for Industrial design was, it is the point where Engineering and Art meets to satisfy the consumers need. And this is not only how the product should look like, but also the cost effectiveness, how it’s going to be manufactured and to make a direct influence in the market.

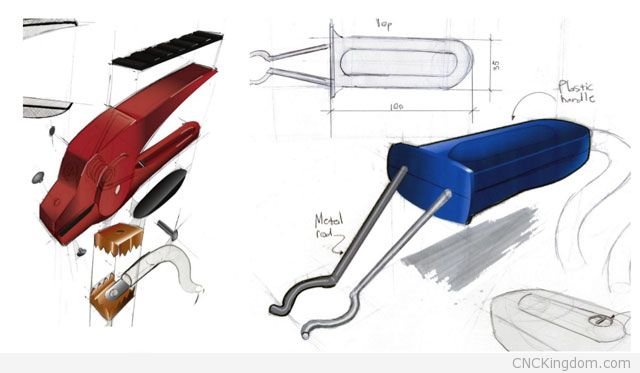

You have some very impressive technical sketches – is this ability something you taught yourself or did it take you a while to learn while studying industrial design? How do you go about developing your sketches?

Drawing sketches is something that I started doing when I was a little kid, I was born with the ability to draw something on paper exactly how it is in real life…but there is a difference between artistic drawings and Industrial design sketches. These sketches are much faster and your page layout should like you are busy building the design step by step by taking everything in consideration.

The techniques was part of my course and had drawing classes for two years constantly, some people can sketch better that others because they have that ability to translate words or ideas into 3D objects.

I notice a lot of SolidWorks modeling in your project – how long did it take you to become proficient in this software package and how does it compare to other software packages you use to create designs?

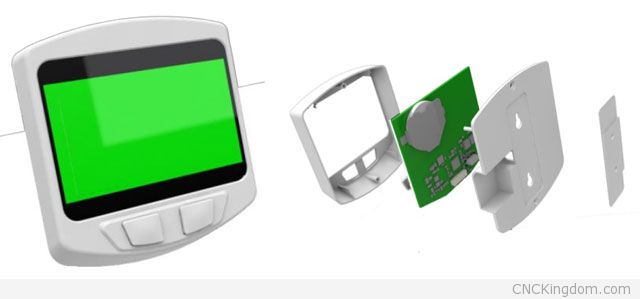

Solid works is one of the CAD programs which can be used, everybody have their own perspective of what should be used, but I really find Solid works very user friendly for fast and effective modelling and rendering purposes. The best way to learn the program is to go into detail with your designs, make it exactly like it would be in real life. I’m working with solid works now for 4-5 years. I can use other CAD programs it is all the same principles because you have the coordinate system. Other programs like adobe illustrator and photo shop also came in handy if you want to add some graphics and colour to your sketches, product renderings and presentations.

I really like your easy bird feeding product, how did you come-up with the idea and did you ever go into commercial production with it?

The bird feeder product was something that I did for somebody else, I thought that it was a great idea to put on my portfolio…I like to extend the variety of products in my portfolio. So the idea wasn’t mine it actually existed and somebody wanted me to redesign it, to look better than the one he saw. He will probably do something with it one day.

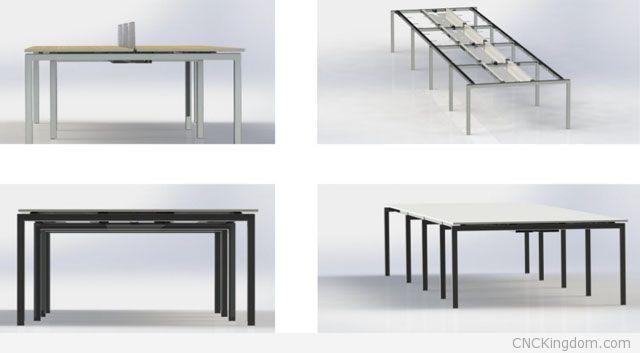

You focused on office furniture, specifically manufacturable furniture (DFM), what are some of the challenges you have building furniture for this area? What are some special things such as tolerances or safety guidelines that you must follow?

I’m a permanent employee in Johannesburg, so my job is to put design concepts into production…most of the time I have to make other designers ideas work in the factory. The challenge is communication from start to ex-factory, first you need to understand the idea, you have to process the design in such way that a factory worker will understand what he should do by drawing and excel sheets. The factory doesn’t care about aesthetics, so you as designer should guide everybody so that they don’t slip up (the more the quantity the quality drops). Something very important is to check everything up, trust nobody, and save your own ass. You really don’t want to please and explain if a whole floor was manufactured wrong. So, I wouldn’t say that I’m working 100% as an industrial designer…. also as a designer for manufacture from point to point.

In my free time I do Industrial design freelancing which I really enjoy doing, I don’t like to share my personal ideas where I’m working… THEY WILL ABUSE ME. I will rather put ideas into production and learn manufacturing during the day and in my free time help other personal clients with product designs. If you do it that way you will always get credit for your personal hard work. It is sometimes very time consuming and it’s a life style not a job, otherwise you will never do it.

How well did Tshwane University of Technology prepare you for the craft that you current do? What are some things you really liked and disliked about the program?

Tshwane University of Technology started with Industrial design in the year of 2008, so the course was very new and I started 2009-2011. All subjects were still in a development syllabus, but still the university is not going to make you a designer they only need to spread the word and if it really is your passion you will become a designer. TUT was great, one thing that makes them unique and different from the other universities in South Africa is that they take you a bit closer to Engineering , Materials and Manufacturing because you can’t just draw pictures, you have to engineer them as well, otherwise the manufacturer will engineer them and it will not end up like your picture.

I think that TUT can organize some internships or competitions, for instance designer of the year can go and work for some company…. They can also work with engineering students, it is extremely hard to get a job, and is very competitive out there; students should compete with each other from 1st year of studying.