You want to buy a laser? READ THIS!

I’m in somewhat of a unique position, I knew NOTHING about CNC equipment, much less lasers, routers, waterjets and plasmas when I started designing projects here at CNCKing.com. I made assumptions, wrote a few books and THEN had the opportunity to work at Evright.com to learn ABOUT lasers.

I guess I started CNCKing.com in a very sweet spot in the industry overall, laser (and generally, CNC equipment) was just STARTING to go mainstream and here I was, offering designs for those that bought them and were interested in designing for them. It was the perfect business at the perfect time in the perfect environment. The planets aligned and I got on the train before it left the train way before it left the station!

After I left Evright.com to start my business, CNCROi.com providing custom design and production services mostly across North America, I began to notice things. It started way back when I ran CNCKing.com but was so insignificant that I didn’t pay attention but now, in the industry, I see it more and more.

Many years ago, CNC lasers were expensive, bulky and… did I say expensive? Well, now you can buy a laser for less than a thousand dollars! Yes, for the price of a lens in my Trotec Speedy 400 flexx, you can buy a whole laser! What a deal! So, lots of people have been buying the cheap Chinese crap and “starting a laser business”.

https://vimeo.com/174256249

The reason I removed the real-time chat on CNCKing.com was because I was tired of people asking me over and over for free designs. The demographic is different at CNCROi.com but guess what, the same people who shouldn’t have what they do have started heading over their asking me for settings. Seriously?

Last week, an American started-up a chat with me and was wondering what settings are optimal for cutting PAPER! Seriously, this isn’t a joke… PAPER! He paid a few thousand for an “imported laser machine” and was asking me what settings I use to cut paper as he wasn’t getting good results.

LEARN TO DESIGN!

A laser and by extension, any CNC machine is not a magic box where you just tell it what you want and voila, it comes out all shiny. If you can’t figure out how to cut paper with your laser, you need scissors, not a laser.

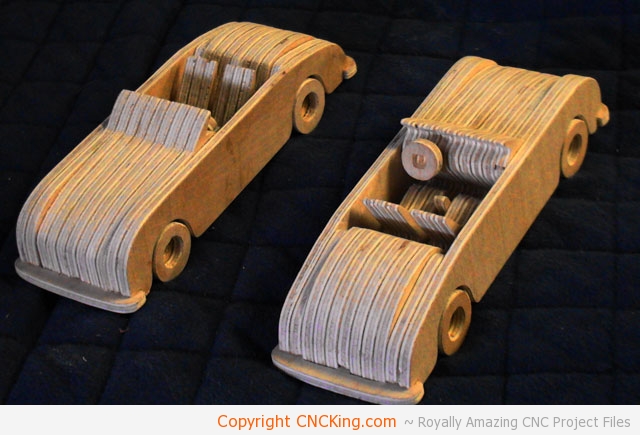

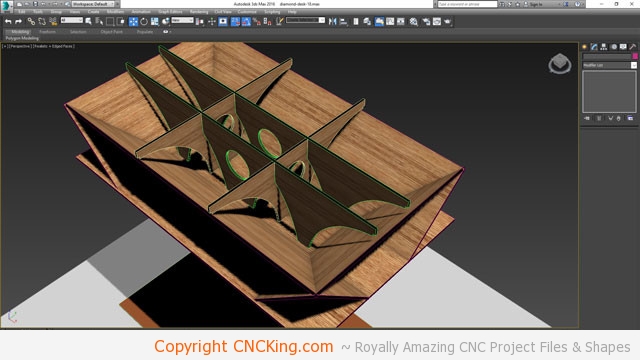

Designing for this equipment is honestly the most fun part of the whole process! The laser just cuts what you designed, buy yourself CorelDraw and play with text and work your way up. I also wrote a bunch of books once you’ve graduated beyond 2D to make full-on 3D objects with your laser, router or any other CNC equipment you have.

The very first project, guaranteed, will require you to design something so while you are shopping around for a CNC laser, router or whatever, at least get your feet wet and learn how to make stuff so that you are one step ahead when it comes to actual PRODUCTION.

GO FOR A DEMO

Before you buy a laser, go see the sales guy for the machine you are interested and go for a demo! Your Chinese friends don’t want to meet with you to show you how wonderful their machine is? Easy… don’t buy from them! This may sound harsh but if they can’t even meet for a demo, then how will they FIX THE MACHINE WHEN IT BREAKS? If you need to fly there for the demo, have fun flying over there after the sale.

You want to buy a machine directly from the manufacturer or a rep who has been in the business for YEARS. Again, demo is where it starts, go for a few of then, go to open houses… but whatever you do, don’t fear asking dumb questions and asking them over and over the same question.

There are so many variables, from speed to power settings, that you should have it as a given that most of the stuff you “hear” will go over your head, it took me a while to fully grasp this stuff myself at the beginning. I REALLY didn’t understand this stuff until I got my own laser but that being said, this is why I encourage you to go to several demos to at least get the basics down.

CNC machines are NOT COMPLICATED, you bring a design in and press a button, it’s all that stuff before, during and after that requires creativity and has challenges.

WATTS? SPEED? COLOR?

Each laser on the market has their own color but at the end of the day, you are buying for two things, watts and speed. Higher watts generally means faster speeds while higher speeds can mean less accuracy. To keep things simple, what you want to do is buy the laser machine with the MOST WATTS YOU CAN AFFORD. Worry about speed and other settings and configurations later down the ordering process.

For instance, my Trotec Speedy 400 flexx has 110W CO2 and 30W fiber. This has plenty of power to do just about anything EXCEPT metal-cutting. I knew that coming into the game and as a result, bought the best machine I could afford with the optimal settings I needed to run a business.

Not all tubes are created the same! For instance, that Chinese 100W tube that you can buy for just under a thousand dollars IS NOT THE SAME TUBE IN MY TROTEC! Watts are not watts, there are other variables with the tube but let’s just say, you can buy a bicycle or a tank, both will get you A to B but if there was a zombie apocalypse, my guess, you’d go for the tank. Laser are no different.

“What are your settings” means NOTHING!

What people don’t seem to understand is that the settings I use for my company are not going to be the same as you use for yours, even if we both have a Trotec 400 flexx with same laser power settings. There is some variation, although very slight in this case, machine to machine even if it’s the same model.

You bought a Glowforge and want to know my settings for cutting through 3/4″ Pine? Yeah, that’s not a conversation that will go very far. Now, laser owner to laser owner, we do share some tips and tricks but at the end of the day, they are just “general knowledge” and nothing that is set in stone. What might work great for me might not for you and vice versa.

Who should I buy from?

Generally, you have a blue or red door, it depends on what you want to do with your machine, the settings you need and your budget. The reds have incredible engineering and precision, as doe the blue ones but end of day, meet-up with both and see what suits you best.

I bought a red one, and have never regretted that decision, the support has been amazing, the quality of the components and precision I get have been a real winner for my shop!

Your business is CREATIVITY

Something I didn’t fully realize when it came to starting my own custom CNC production shop was how much creativity I’d need, and how lucky I was to have taught myself the hardest to the simplest design approaches when it comes to production.

From making live edge wall plaques to medical and military projects, there is a never-ending range of materials, application and processes involved! It’s wonderful learning from my customers and vice versa about all this, it’s creative, collaborative, challenging and most importantly, NEVER THE SAME!

If you are not a creative person, not able to learn on your own and play with your equipment to utilize it as per customer specs, don’t buy a laser or CNC machine as you aren’t ready. Yes, you are being paid well to push a button, but it’s everything around that button that’s important, not that button alone.