Unlimited Commercial Production for 7.95$?

Every once in a while, I get a complaint from a potential customer who can’t understand why they are unable to buy a digital file from WoodMarvels.com once for say 7.95$ and cut unlimited amount to sell in the back of their van or in local shops. I do sell commercial production licenses with wholesale discounts so it’s even less! To them, giving even a fraction of their income to support the designer (it’s not just me on WoodMarvels.com btw) is like slowly pulling off their nails – they want all the money but none of the work or investment required to make the product they wish to sell possible.

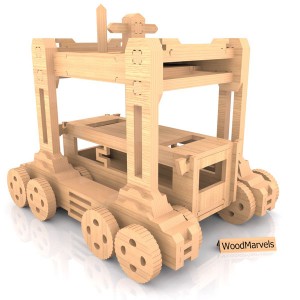

CNC Straddle Carrier Woodworking Project

So I’ve decided to break down the amount of work that’s going into the upcoming launch of the Straddle Carrier B CNC project go shed a little light on the costs that go into making a model these days.

- It took roughly 20 hours to design the original laser version.

- It took about 20 hours to redesign, cut and assemble the latest working CNC version (it’s cut using the same 6mm thick plywood as the laser model BUT at almost double the scale, some serious re-engineering is required to make it work).

- Video production required a 3 000$ video camera plus another 1 000$ in accessories, a 7 000$ CNC machine, 4 000$ in software and soon require the investment in a new 10 000$ industrial workstation

- Rendering the animations for the Straddle Carrier (both versions) is well north of 200 hours (hence the need for a new computer soon to drop that bottleneck down).

- Few hours spent uploading, paying the host, paying paypal a % of sales etc…

Taking this into consideration, the upcoming Straddle Carrier B CNC that will sell for 14.95$US is an absolute deal! I’ve excluded the years of work it’s taken me to learn how to do all of this via trial and error as there were no manuals to learn how to do this stuff – which is why I wrote my three WoodMarvels.com books to save others the trouble and time! I never took a course in engineering, 3D modeling, video production or film-making (I know these live videos looks amateurish at best but each will get better – and with time, less amateurish!)

ShopBot’ing a CNC Platform Crane: Proof of Concept

Good luck if you can find an engineering firm that will give you the rights to commercially produce an unlimited amount of models for this price – even a Chinese firm wouldn’t give you the time of day at these rates! Now you know why WoodMarvels.com is unique – if you aren’t passionate about this industry there is no way you’d have enough energy to do all of this and still have a huge smile on your face when you wake-up in the morning!

Is WoodMarels.com Profitable?

Yes it is, and the side benefits I’m starting to receive from all this mountain of work make it all the more fun! It has allowed many of my dreams to become reality, given me opportunities to meet amazing people from around the world and has taught me enough knowledge to fill volumes of books! That being said, there is always room for improvement – and I continue to invest heavily into making things better for both the CNC/laser industry and customers alike.

3DMarvels.com

3DMarvels.com is the sister site to WoodMarvels.com but focused entirely on the 3D printer industry – right now, 3D printing is still bloody expensive but I see huge potential and when I’m not working on WoodMarvels.com, I’m working on 3DMarvels.com.

As I’m slowly doing with WoodMarvels.com – redesigning my laser cut models to be CNC’ed, I will be doing the same for the 3D printing industry – redesigning all my laser/CNC models to be 3D printed. To say this is a tremendous amount of EXPENSIVE work is an understatement but to me, it’s the challenge. I’m not the best modeller, designer or what-have-you but I accomplish my goals regardless of my limitations because I just don’t give-up. I see a mountain ahead of me, and even if my only equipment is a pair of flip-flops, I will reach the top! Other designers with far more skill and talent will join the site to round-out available digital files as has happened with WoodMarvels.com.

1911 Ford Model T Torpedo Runabout: Laser Cutting Video (720HD)

1911 Ford Model T Torpedo Runabout: 3D Assembly Animation (720HD)

ShopBot’ing a 1911 Ford Model T Torpedo Runabout: Proof of Concept

https://vimeo.com/202820896

1911 Ford Model T Torpedo Runabout CNC: 3D Assembly Animation (720HD)

Why do I need to redesign my models to be 3D printed? The easy way is to basically print the individual parts like I have now for my models and expect the customer to glue it all together – the hard part is re-engineering a toy to work, with moving parts and with lots of additional details – to be 3D printed in whole and working right after without any assembly required. Those working digital models will be selling at a higher price point due to the exponentially higher production costs (I can’t make them using an extrusion machine, it must be a REAL 3D printer such as the ZPrinter from 3D Systems that I’m eying and had the opportunity to play with when I visited their HQ a few weeks back) but rest assured, this will improve my designing skills tremendously and applied to future CNC, laser and who knows what else I end-up producing for later!

1911 Ford Model T Torpedo Runabout: 3D Printing Animation (720HD)

Where is the NEW stuff?

Right now, I’m focused 100% on bringing-up the CNC catalog somewhat equal to the laser one on WoodMarvels.com while writing my 4th volume based on CNC – as I will with 3DMarvels.com in the near future. That being said, there is still room/time for designing new stuff. Lots of stuff… but you will have to be patient – my single biggest bottleneck continues to be my computer and once that dragon is slayed (hopefully a few months from now), the model release cycle will be vastly improved.

You can read more about my production philosophy here: Fair Compensation: A Business Dilemma