Thinking of buying a used CNC laser? Beware!

As a follow-up to my previous blog post about branding issues with Chinese laser manufacturers, the next step down the totem pole for most shops looking for a cheap laser are going the used route.

My Situation

I bought a new Trotec Speedy 400 flexx, it had the nice factory smell out of the crate, for me, going used was NEVER an option. The problem with finding a used Trotec Speedy 400 flexx in Canada at the time was that there were none, I was the first one to have it in this country!

I did have a lot of other options, finding a used (name your laser manufacturer) by contacting the manufacturers directly is the best approach, you’ll read about why later in this blog. Companies are always changing, what they bought years ago may not suit them anymore for various reasons and you can stand to get a very good machine for a lot less, sometimes still under warranty.

Things to watch for

LASER TUBE

The money you spend on a CNC laser is directly proportional to the value of the tube, never forget this. The lower the price, regardless of the condition of the machine, the less value the tube has as it’s such a significant % of the overall value and price of the machine.

Different tubes have different lifespans even if they are the same, a glass tube lasts the least, a ceramic one the most. A fiber tube may have less wattage (30 watts in my case) but it costs significantly more than the equivalent in CO2. YAG is somewhere in-between depending on specs. So, if you see a machine with a 50 watt fiber tube for the same price as a 50 watt CO2 tube, something is up.

To add to the complexity, you also have to contend with leakage. CO2 tubes lose power over time, that brand new 130 watt CO2 machine bought new 5 years ago is no longer 130 watts today!

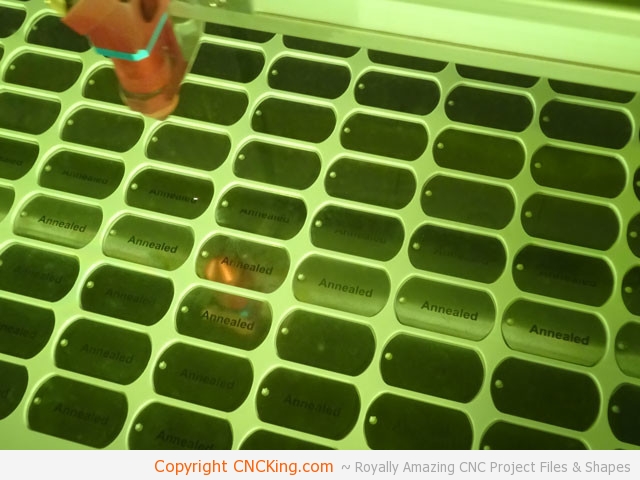

This is why you MUST ask that the tube be checked, takes less than a minute, to find out the TRUE wattage, don’t negotiate based on stickers, negotiate based on actual testing!

ALIGNMENT/FLATNESS/SQUARENESS

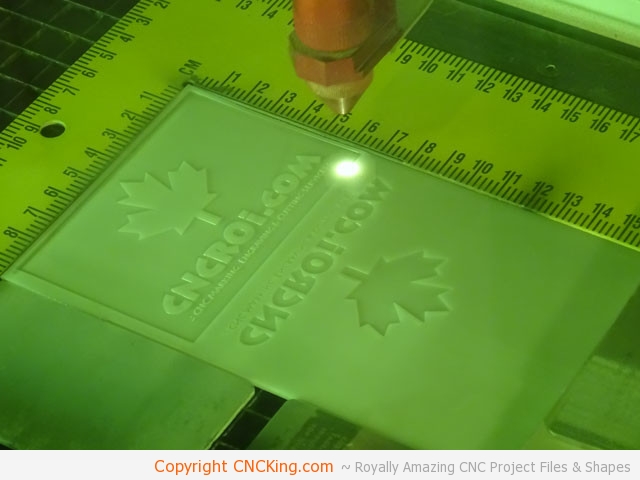

How do you test to see if a laser is properly aligned? Laser cut a circle, cut a few of them (you can engrave too), regardless of the media, you shouldn’t see any “overlap” and you should have a closed loop. If the starting and end point of the circle don’t match, something is wrong and it needs to be fixed.

Also, test odd shapes and sizes, just to verify that the start point of the laser is the same as the end point. If your table isn’t perfectly flat or level, you’ll also see variations in engraving and cut quality as well. Don’t just cut a rectangle that’s 2 inches by 1 inches and base your buying decision on that. It’s too easy.

CLEAN MACHINE

I understand you are buying a used machine, but at the very least, you should have a clean lens and machine. If the lens is black, walk away. If the machine is dirty, walk away… this isn’t a used car that was left in the wilderness for 10 years, it’s a CNC laser that should have been well maintained and kept in tip-top shape. At the very least, the company should have cleaned it BEFORE you walked in the door out of courtesy.

Now, if you see the CNC laser bed all scratched-up, that’s fine, ask about getting a new one put in place… that’s really the least of your worries. It just shows the person who used the machine before actually USED IT which isn’t a bad sign.

Scratches and dings on the laser itself are nothing unless they cause the entire frame to go out of alignment. Even my NEW machine, after a few months, has a few scratches on it… from moving material on the bed and around the machine.

WARRANTY

If you are buying your machine from a quality manufacturer, it should have a warranty. If it doesn’t, just don’t buy it and move along. It’s a good idea to ask about extended warranties as well. Yes, the offshore laser guys will have a warranty, but if you have to pay for travel expenses, room and board… it’s useless. Make sure things can be fixed as locally as possible and ask about EMERGENCY situations.

“My laser blew the tube and it’s 1 am and I have a project due noon tomorrow, what would you do?”

Good answer “No problem, you come to my showroom and finish the work and we’ll set you up with a replacement within a few days, if not, we’ll ship you a loaner machine.”

Bad answer “It never happens so don’t worry about it” (what they are telling you is you are F#cked and not to bother them as soon as they get their money)

SALES GUYS

There are GOOD sales guys and there are BAD ones. It’s often too late when you discover which you’ve been dealing with. Regardless of what you are TOLD, make sure to have everything in writing, including the tube power tests (they should do this right in-front of you), type of lens you will be getting, warranty information and payment terms.

A GOOD sales guy will do this automatically, not for your protection but for THEIRS, a bad one won’t care. Remember, you want your sales guy to be a bean counter and methodical, not your customers. I’m a bit different with my approach to sales, being a bit more creative but at the end of the day, I make sure that expectations are CLEARLY outlined.

DON’T TRUST THE INTERNET

Here is a fantastic case in point to illustrate this. A&E Magazine wrote a great article about USED LASERS, you can read it here “Used Lasers—A Great Deal or A Great Pain“. Give it a read, and you, like me, might be SERIOUSLY tempted to contact Access Business Solutions (www.usedlasers.com) as hey, they sound like an expert being quoted by a magazine.

READ THIS: WARNING concerning Access Used Lasers

That “good idea” doesn’t sound so good anymore does it? The point I’m making is that regardless of what you read online, you are buying capital equipment that yes, you are trying to buy on the cheap, but is still a significant investment in time and treasure. If you can’t meet with anybody in person, DO NOT SEND THEM MONEY OR BUY FROM THEM. You aren’t buying a keychain!

When I bought my brand new Trotec Speedy 400 flexx laser, I knew the people I was buying it from personally for more than two years. Simon, the director of Trotec Laser Australia taught me everything I know along with his son Reece and the staff at Evright.com. I shook their hands so much through those two years that no handshake was required when I closed the deal, only banking information! I used their equipment, got to know the whole team and I seriously couldn’t have had better mentorship before taking the plunge myself in short notice.

It gave me confidence and I knew the pitfalls of getting into the custom CNC business before I even started – that’s why my buying decision from saying “I need to buy one, how much” to me running to the bank to give two deposits on my machine took less than an hour to happen. It took so long because I literally ran to the bank!

I realize I’m a special case but I can only hope that you have a similar circumstance before you jump into the industry and buy your first laser or any other CNC equipment. If your plan is to treat the laser like a used car and drop in, give your cash after kicking the tires and leave with a thriving business… you are in for a world of hurt.