Steve Fox, Head Greenskeeper at Urban Putt (USA)

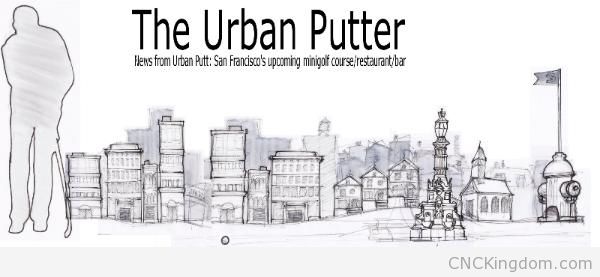

Imagine an indoor mini putt course built with the precision of CNC machines by passionate designers who push the outer limits of creativity all so you can have fun putting a little ball in a hole a few meters away. This is the promise of Steve’s Urban Putt concept that he’s eagerly trying to make a reality thanks to supporters around the world on Kickstarter.

You can visit his dream becoming reality at urbanputt.com and participate in their campaign at http://www.kickstarter.com/projects/239410384/urban-putt-miniature-golf-like-youve-never-seen-it

Before we run into too much detail about your project, can you tell me how you first got into mini-putt and how that coalesced into the concept of using CNC machines and other mechanical wonders to build the ultimate INDOOR mini-putt course? What is it about your background that makes you so comfortable with such a massively complex project?

Back in 1993, my wife and I threw an indoor miniature golf party at our house. We billed it as a “bring-your-own-hole party,” and 25 friends showed up with all kinds of simple tubes and obstacles, and a tradition was born. By the time we threw our final party, dubbed “Crawfox Minigolf’” (my last name is Fox, my wife’s is Crawford), the event had morphed into a 200 person benefit, with incredible constructions that stretched the boundaries of what is possible in mini-golf. (All the holes are cataloged at our personal site, crawfox.com). Somewhere along the way, we even installed three tubes in our home’s walls so you could putt into a wall in an upstairs bedroom and have the ball come out in the kitchen downstairs.

Back in 1993, my wife and I threw an indoor miniature golf party at our house. We billed it as a “bring-your-own-hole party,” and 25 friends showed up with all kinds of simple tubes and obstacles, and a tradition was born. By the time we threw our final party, dubbed “Crawfox Minigolf’” (my last name is Fox, my wife’s is Crawford), the event had morphed into a 200 person benefit, with incredible constructions that stretched the boundaries of what is possible in mini-golf. (All the holes are cataloged at our personal site, crawfox.com). Somewhere along the way, we even installed three tubes in our home’s walls so you could putt into a wall in an upstairs bedroom and have the ball come out in the kitchen downstairs.

Crawfox Minigolf effectively took over our lives for months out of the year, and took a serious toll on our San Francisco home. We stopped doing it when it simply grew unmanageable for two people with two kids, plus full time jobs, to continue doing. But we both missed it, which ultimately led to my decision to make this into a commercial entity. My day job, for the previous 35 years, had been in publishing, where I routinely oversaw complex projects and managed large staffs. I had been managing editor of Omni magazine in the 80s, and editorial director/editor in chief at CNET, PC World, The Web magazine, InfoWorld, and Affinity Labs during the 90’s and 2000’s, so creating something ambitious didn’t scare me.

The weather in California is generally mild and very favorable, why did you decided to build this high-tech mini-putt game inside rather than outside? You’d think building a course outside would give you a lot more freedom than trying to get it to work within an indoor structure. What are some of the challenges you faced going this route that you didn’t envision?

The weather in California is generally mild and very favorable, why did you decided to build this high-tech mini-putt game inside rather than outside? You’d think building a course outside would give you a lot more freedom than trying to get it to work within an indoor structure. What are some of the challenges you faced going this route that you didn’t envision?

Well, weather in southern California may be consistently mild, but in San Francisco, the conditions are much more variable. Everyone cites the quip, wrongly credited to Mark Twain, that “The coldest winter I ever spent was a summer in San Francisco.” Twain may not have actually said it, but there’s a lot of truth there. Besides, I had a concept of a true urban experience, a break from minigolf tradition. Indoors seemed to be the way to go.

The biggest challenge, however, turned out to be a rather simple one: cost. Real estate in San Francisco is among the priciest in the nation. Even as a renter, we ultimately had to flesh out the concept by adding a restaurant and bar to Urban Putt to make it financially viable.

You have an incredible team behind this urban putt concept, can you give a bit more details about each member and what they bring to the table to turn your ideas into reality? How did they find-out about the project?

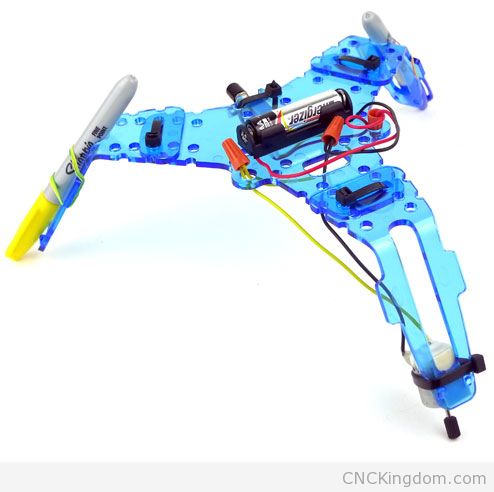

Our lead designer, Chris Myers, is a mechanical genius—a guy who can construct just about anything. He spent years as the lead designer at Wild Planet Toys, where he won a “Toy Line of the Year” award, and taught for years and the San Francisco Academy of Art University. He’s currently an instructor at UC Berkeley. I met him years ago, when my son attended a workshop Chris was leading that taught kids how to build robots.

His partner Anne Mayoral, my project manager, has an even more diverse background, having been an aerospace engineer for years, before deciding to follow her dream to become a toy designer. SO when we say that “you don’t have to be a space scientist” to do this work, we usually follow up with, “But just in case, Anne is She and Chris formed ArtBot Toys two years ago and launched it at Maker Faire. You can visit them online at http://artbottoys.com.

Most of our other constructors are former top students of Chris from the Academy of Art who naturally gravitated to the project once they knew Chris and Anne were onboard. We also advertised with the American Institute of Architects for summer interns, and we got several talented students. Somewhere along the way, local artists read about what we were doing and contacted us about participating. For instance, Andrew Roth, a nationally known sound designer (http://online.wsj.com/news/articles/SB10001424127887323339704578171641182156944) called me out of the blue and announced that “I must do the sound for your mini-golf course.” He’s now onboard.

I read in your “risks and challenges” some astronomically high fees you are going to be charged should this project get enough funding to go-ahead. $126,000 in Transit Development Impact (for the extra strain we will place on the public transit systems); $56,000 wastewater fee; more than $50,000 in building permits. Have you seriously considered relocating to a more favorable location where the equivalent of half of your construction costs (over 500K) wouldn’t be eaten-up by government fees? That’s a huge amount of money that could have gone into so many other areas of this project.

I live in San Francisco, and I love this town. So I was insistent about doing it here—despite the almost unsurmountable obstacles. If this works, I’d like to try it elsewhere, but for me, everything starts in my home town.

I know when I was a child, mini-putts where EVERYWHERE, for some reason, they are very hard to find nowadays in most cities. What happened to them and what are your plans to avoid the same fate once the novelty wears out?

I’ve really rethought the conventions, trying for something that has legs. For one thing, being able to enjoy a good meal and beverage, before, after or even during minigolf adds a whole new dimension to what we’re doing. Also, we will be changing out holes periodically to avoid minigolf fatigue. Meanwhile, we are playing up the spectacle aspect of this: People can sit around enjoying a meal or drink and observe the goings-on on the course.

You recently bought a ShopBot Buddy which roughly fits in between my ShopBot Desktop and a full-sheet router as far as cutting area. I couldn’t see many aspects of this project even being possible without a CNC machine, should you get full funding, do you plan on acquiring more CNC machines to greatly compliment your production speed and precision? How has it performed thus far? I’ve had mine for two years now and not a problem in sight! Why did you go with a CNC router first vs a laser/plasma cutter?

I’m unlikely to acquire another CNC machine unless we decide to take the concept nationally. The ShopBot Buddy pretty much does what we need it to do for now, though it isn’t exactly fast. We keep it running for about 10 hours a day. We actually have access to a laser cutter elsewhere that we can rent time on, so the CNC router made sense as a purchase.

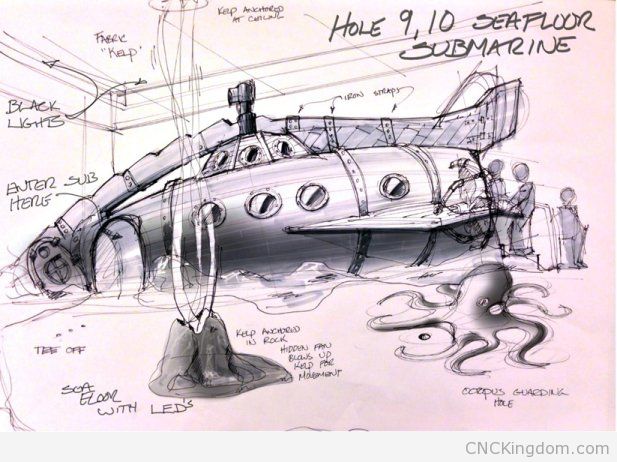

Your video is incredibly well produced and the concept drawings are amazing! How much does media production help in keeping the overall vision of this project on-track as it’s very much a “design as we go” steam you’ve established.

I’ve hired a team of people with high standards and strong design sensibilities. We like to say that we are shooting for the best possible experience and the most aesthetically pleasing constructions in everything we do. So we come in with a low tolerance for compromise. We’ve had to scale back some of our plans, but we take solace in knowing that we can keep revising and upgrading after we open our doors. All of our designers are excited about that prospect.

What are some of the biggest challenges you’ve had to face thus far bringing this project into fruition? What is some advice you’d have to anybody thinking of undertaking a project of this magnitude?

The biggest challenge, by far, has been raising the money. I don’t enjoy asking people for money, even though I believe it is a good investment. But I’ve had to learn how to make the pitch—with spreadsheets, PowerPoint, a beautiful produced business plan, and an actual sales pitch. That has allowed me to raise nearly $1,400,000 so far, which has kept the ShopBot running, the employees paid, and so on. I’m still out there struggling to get the rest.

I’ve launched a KickStarter campaign http://www.kickstarter.com/projects/239410384/urban-putt-miniature-golf-like-youve-never-seen-it to raise an additional $50,000, and that is moving along, but not as fast as I’d like. I think we’ll make the goal, but it will be tough.

My other advice is to tap experts for advice. Don’t be shy about admitting what you don’t know. Find people with real expertise and hire them to help. If you try to do it all yourself, you likely to fail.

You can visit his dream becoming reality at urbanputt.com and participate in their campaign at http://www.kickstarter.com/projects/239410384/urban-putt-miniature-golf-like-youve-never-seen-it