Scot Farley, Principal Designer F3 Industrial Design (Australia)

I love it when I get to interview somebody who is not only incredibly passionate about what they do but have the knowledge and expertise to back it up. Scot Farley is one of those rare people who live their dreams everyday and have blue arms because they keep pinching themselves to make sure they are really awake!

Scot Farley is the Principal Designer and owner of F3 Industrial Design which specializes in “first to world” products and start-up projects. He’s the guy you want to talk do if you have an incredible idea and want somebody with the contacts (investment to manufacturing) and expertise (design to marketing) to help you bring your innovation to life in a profitable manner!

You can visit his company at http://www.F3id.com.

Ironically the first domain I ever registered and parent company of all my businesses was i3ds.com and I only got it because Dassault Systèmes beat me to 3ds.com which would be worth a fortune if I had thought of it just a little earlier! Like an inventor, time to market and luck play a critical role for achieving success!

What business did you start when you were 10 years old and what did you learn from the experience? At that age, I started my first business as well, selling Siamese kittens… invested a few hundred in the mother, a few hundred in the stud service and then a few months later, kittens… that nobody wanted to buy so we had to give them away! hahahha I learned not to count $$$ until it was in my hand!

I lived on a farm in those days and although it is something I couldn’t do these days I had a business trapping possums.

I lived on a farm in those days and although it is something I couldn’t do these days I had a business trapping possums.

We had a lot of orchards nearby and the farmers had a real problem with the possums eating all of their fruit as they were in plague proportions. I had a look at the existing technology of trapping and knew I was going to have to find an alternative. The animal was trapped by the leg in a steel “gin trap” and had to endure a lot of pain until the trapper came around and killed it. Animals that were left or forgotten about died of starvation.

I knew that the orchards needed protecting but couldn’t use those traps if I was going to be involved in the industry. I researched the options and found a company making a product that was far more humane and killed the animal instantly so I used these and kept the possums under control that way.

It makes me wonder how I did that job these days as I love possums and even back then I had them as pets but life is quite a lot different on a farm and you are more immune to that way of life.

I managed to buy new traps with the profits and built the business up to include a number of farms and even managed to buy my on motorbike which I used to run the traps.

You had incredible academic success while attending Queensland’s University of Technology in Industrial Design – how important was that schooling for you at the time and how large of a role did it play in your entrepreneurial / design career?

It’s funny but I’ve never really been that academic and in fact I had to go back to night school to even get into University. Once I started the course I did really well in it because I was so passionate about the industry it would lead me into.

I worked really hard and even though I was looking after my younger sister and brother, playing rugby and working two jobs I still got great grades in a notoriously heavy duty course. I remember I was vying for the deans award with another guy and when running from work to the library I got a stabbing pain in my chest that knocked me off my feet.

I decided there and then that I would stop pushing myself so hard and dropped back a few gears. The other guy got the award but the fact is that no-one has ever asked me about my grades since I left Uni and I am a firm believer in a more balanced education that incorporates working in the chosen field so you can get the practical experiences that will help you in your career and in fact it was my work experience was what got me into my first job and the grades were secondary.

I don’t believe the education process helped me with the Entrepreneurial side of my career at all. I believe I was born an entrepreneur and I actually think the education stifled me in that area quite a lot. With entrepreneurial endeavours you are always looking at the big picture and the education made me focus back into the detailed work and the two are really at odds.

I am able to make the distinction these days and am using both skill sets to develop some new and exciting ideas.

What lead to you to begin your own industrial design firm, F3? How did you come-up with the name and find your first clients?

I always had an end goal of having my own company and there was a lot of writing on the wall that my employer was going to eventually outsource my position. I figured I wouldn’t wait for that to happen and decided to make the jump and figured he could then use me as a contractor. Unfortunately the writing on the wall was a bluff and was designed to keep me and my wage on a close tether. Obviously now the plan to do his work on contract didn’t exist so I was starting from scratch.

This was a difficult time I won’t lie and I lived on basically nothing for a quite a while. The advantage I had was that I am an Inventor at heart and am extremely passionate about Invention and its ability to make positive change in the world. I used this passion to create a niche in the market and focused on Inventors and start up companies that my peers call “D” grade clients. I made these my “A” grade clients and learned how to service their needs.

The skills I honed working for them were also very beneficial to commercial clients and now I have a blend of Inventors and Commercial Clients that I service.

The name F3 comes from the three fundamental aspects of design you need to get right in order to develop a successful product. The Form, Fit and Function of a product , the three 3’s are there to remind me to always get the fundamentals right and this will ensure the product suits its application.

What is a “100 year change project” and what role did you play in them?

100 year change products are otherwise known as disruptive products and they come about when you take an industry that has been doing things the same way for hundreds of years and improve on their technology to turn that industry on its head.

A good example is apples iPhone, while everyone else was making phones in a certain way, Apple threw all of that benchmarking away and took the harder path of actually developing a phone that used new technologies and formats to enhance the user experience to the stage that other systems became obsolete and they gained a major share of the market by taking this line.

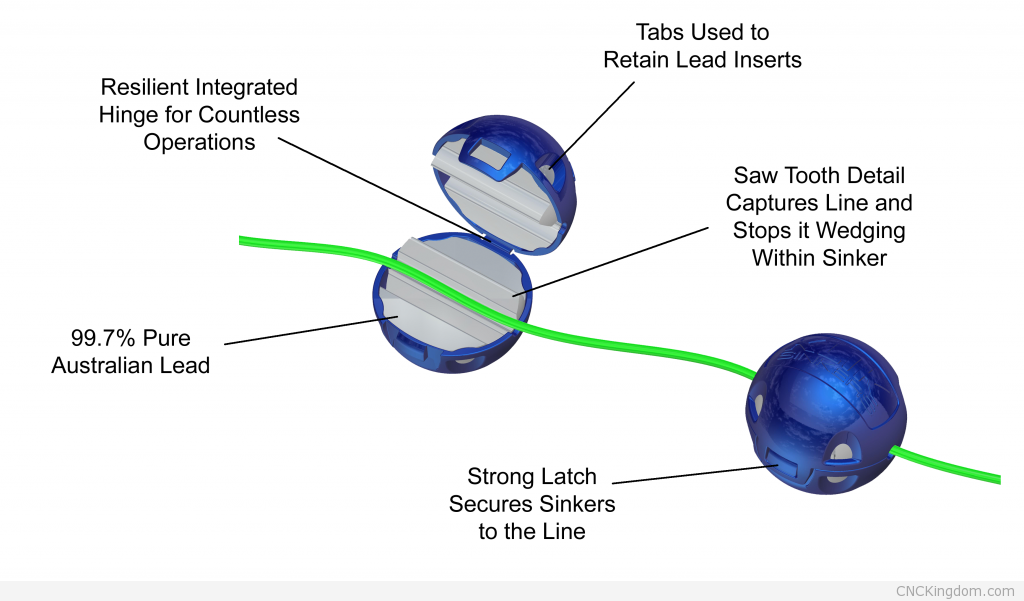

I actually have a project of my own that is an 8000 year change. I recently developed a fishing sinker (www.kliksinkers.com) that you can snap onto your line instead of having to cut it, fit a sinker and then re-tie it to your line again. It has an outer case that encapsulates the lead and allows it to be added to and taken off your line at will so you can change weights as required, quickly and effortlessly.

The standard ball sinker has been in its standard format of a spherical lead ball with a hole through it since the Egyptians used them to hold their nets down 8000 years ago.

I am also working on a new packaging solution that will revolutionise the way brewers deliver their carbonated beverages. I can’t disclose this one yet but it is getting close and I am hoping to have it on the market this year.

These sorts of projects normally require a high level of Invention in order to achieve the disruption and that is what sets them apart from other design projects. I have done this for many clients over the years and the rewards can be incredible.

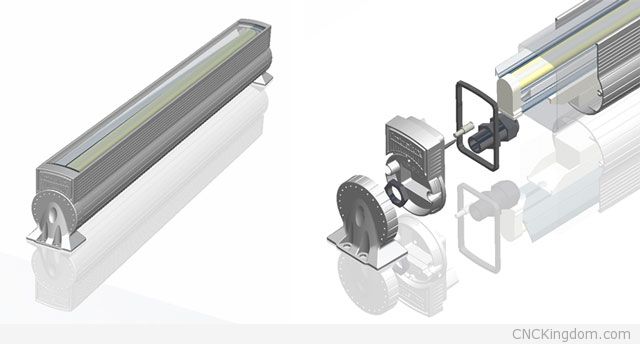

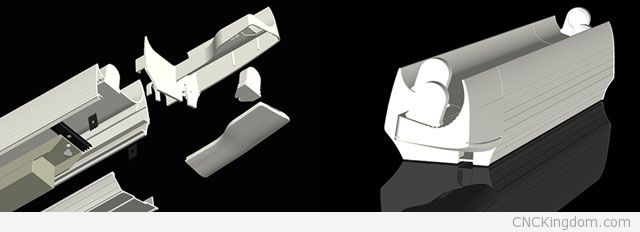

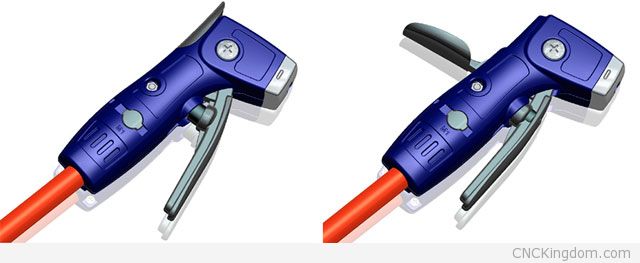

You have a number of very nice projects on your website, which kinds to you prefer working on? The complex mechanical ones like Exterior T5 Luminaire or “simple” ones like the Squattle water bottle?

Thanks for the positive feedback on the site. The projects on my site are quite out of date and there are a number of exciting projects I still need to add.

In answer to your question I am far more excited about the Squattle type projects than the more engineering based products simply because the Squattle was a first to world type endeavour while the lighting projects are more just ingenious ways of packaging existing technologies. Both types of projects are challenging in their own way but to come up with a brand new idea that has never been seen before really takes a lot of thought and is very challenging but also very rewarding.

That is an annoying project actually and it actually progressed a long way further than the image on the website shows but has yet to find success. Having said that the research uncovered by that project has changed the way every perishable liquid is packaged across the world, extending its shelf life and saving billions of litres of otherwise wasted product and that is something the Inventor should be very proud of achieving.

Being based out of Australia, do you apply for US patents first followed by an Australian one? How are their rules different?

Good question. It depends on the product but generally I take advantage of the grace periods offered by the provisional patent. This is an unpublished document but it sets a priority date from when you apply that allows you to develop the technology and get deals in place before you need to commit to a standard patent in individual or multiple countries.

As it isn’t published it allows you the flexibility to re-submit the provisional without having disclosed the art (information about the technology) and losing your novelty if the development is taking longer than expected or if you haven’t secured a deal/partner to help with the commercialization.

There is one major difference in the rules and that is in the US you are able to produce the product and then retrospectively apply for a patent in that country. The application has to be within a year of manufacture but this has the advantage that you know if the project is worth protecting based on its success or failure and also you have cash flow to finance the cost of the patents.

Most other countries I know of consider that once you have produced a certain number of products and sold them you have disclosed the ideas publicly and therefore your product is no longer novel and can’t be patented.

This means you often need to commit to patent costs before the product is proven or making any money, most time when it is still at its most costly stage.

PS: I am not an attorney so don’t base any business decisions on what I have just said, it is just my opinion and you should always see a professional Patent Attorney before making any decisions on Intellectual Property Protection.

What are your views on patents in general? Is it best to focus your time and money on “first to market” or on the patent (provisional or full) first? What are your views on the recent change in the USA from “first to invent” to “first to register”?

I believe that Patents can be a very strategic aspect of a project and that is why I have tried to learn as much about them as I possibly can. I have great attorneys and together with my product and commercial knowledge and their knowledge of the Patent process we can normally use them to very good advantage.

There are a number of strategies that need to be employed to ensure they do not cause a project to fail because of their financial drain on a start up but if they are managed correctly they can be very beneficial and sometime crucial in the success of a business. Knowing this there are always exceptions to the rule and sometimes projects simply do not suit a patent and you are far better off spending the money on marketing in order to flood the market and get your brand recognition to carry the company.

I believe that in order to patent a product it needs to be very unique or you will never get past the examiners as there are thousands upon thousands of ridiculous ideas in the system that can be used to site prior art and knock your product out. This is a result of the lack of vetting that allows anyone to apply for a patent on just about anything and this I believe will be the downfall of the system as it is being cluttered to choking point by what can only be described as doodlings of ideas that have no conceivable chance of ever amounting to anything.

I think the first to register law in the US will now cause the that system to become more like our own with companies being forced to register before they can prove their ideas on the market.

Personally I thought the old system was fairer on the original Inventor and the new system favours secondary (copy cat) type manufacturers and this will not be good for original products that need the chance to evolve without being copied as soon as they are released.

What are some things that inventors normally overlook when it comes to manufacturing their product for mass consumption? Are there some common issues with designs coming out of other firms in general that you have to rectify on a regular basis?

The biggest mistake I see Inventors make is to run with the first solution they come up with. Unfortunately a lot of Inventors have identified a problem and solved it but they have only solved it on one or perhaps a few levels. They put this product on the market and it goes well for a little while until someone sees it and improves it enough that they can apply for a patent in their own right and ends up with a better product at a cheaper price and takes 80% of market share.

It is very important to evolve the product to a point of near perfection before it hits the market. It needs to be as refined as possible so it has the least number of components possible, is easy and cheap to manufacture, is easy to use and does not cause any OH&S issues, appeals to the market visually and achieves all of its functional requirements perfectly. Unless you are qualified to do this then unfortunately employing a professional to is about the only way you have any chance of achieving this.

On the flip side the investment you make on an Industrial Designer usually pays for itself many times over once the product is manufactured. In most cases the cost of employing an Industrial Designer to evolve the product will be more than offset in the savings on tooling that has been eliminated through the refinement of the product and the removal of parts.

The other big cost that people neglect to account for is the initial order and inventory involved when you have an unrefined product that has too many parts. Each of those parts needs to be ordered in quantity (usually minimum orders are 5 000 parts or more) and paid for as well as stocked, assembled and shipped. Every part you remove saves you money for the life of the product and that can really add up.

How can an inventor (or manufacturer) compete against others that don’t follow international copyright laws? You might have an awesome invention, most likely manufactured in China, then discover a little while later that they’ve been running another production cycle for the local/international market without telling you at worse or offering blatantly unfair compensation at best? What can an inventor do to protect themselves in these cases? I don’t want to single-out Chinese manufacturers specifically as this happens everywhere but from my understanding, if you have an Australian or American patent, that doesn’t cover you in China or any other country right?

It’s a hard one to answer and it comes down to human nature and trust. You can either throw your hands up in the air and say I’m not going to play or get in there and if you are copied, try and deal with the best you can.

Unfortunately it is very hard to bring anyone to justice as I found out last year when a JV went astray here in Australia and I ended up doing a year’s worth of work for no return on a new waterproof phone case cover which allows you to touch the screen without a membrane in front of it. It was ahead of the new nuud products from lifeproof and is going really well but the guy won’t pay me a cent of the royalties.

I’ve heard of double shifting in China and when you go to the trade shows you see everything you can imagine being copied. I think the best strategies are to partner with the Chinese operator and take a small percentage of sales. They can’t sell back into a country you have cover in and most times you would have very little chance of selling into China so it a way to open a new market while getting a return on your product.

And no the Australian and US patents don’t cover you in any other countries but they cannot (by law) ship their products into the countries covered without breaching your patent.

Anything else you’d like to add?

I honestly believe that we are set to become one of the leaders in innovation here in Australia if we can learn how to integrate Invention and Inventors into mainstream business.

Our background is in farming and combined with our isolation we have been forced to diversify our skills and adapt what we have to suit our needs. This along with a generally high level of education puts most Australians and New Zealanders (I imagine Canadians also) in a unique group primed to invent new and unique solutions to societies problems.

I think it is time for manufacturers, who are still trying to compete against the manufacturing giants in China making “me too” type components and seeing their companies slowly disappearing before their eyes, to take a step back and re-direct their remaining resources towards unique and protectable products that can command much higher profit margins and start selling these products on the world stage.

I think it is time for manufacturers, who are still trying to compete against the manufacturing giants in China making “me too” type components and seeing their companies slowly disappearing before their eyes, to take a step back and re-direct their remaining resources towards unique and protectable products that can command much higher profit margins and start selling these products on the world stage.

There are hundreds of these ideas around and unfortunately a lot of Australian companies do not have the knowledge on how to integrate them into their businesses and they end up going overseas along with all of the profits.

If we can combine the ideas and the business then manufacturing still has a fighting chance here and we can start to get our import / export balance back in cheque.

Thanks for the opportunity to discuss what I do and I hope some of what I have said helps your readers to get their projects off the ground.