Richard Hinchliffe, Sales Engineer at Direct CNC (UK)

One of the biggest decisions a person interested in a CNC machine usually makes is, once they’ve decided on a machine, is to go the NEW or USED route. Sure, it can save you a bit of money but that comes at the cost of future productivity. Key takeaways:

- Keep your machine in top shape and you’ll attract top dollar when you try to trade it in or sell it.

- Don’t skip out on service or warranties, they are there to protect you and are well worth the investment.

- Don’t like to customers if you are doing sales!

You can contact Richard by visiting http://www.direct-cnc.com.

What did you do before you joined Direct CNC and what made you want to join the industrial market to begin with?

I worked in the accounts department in Europe’s 2nd biggest DVD wholesaler.

I worked in the accounts department in Europe’s 2nd biggest DVD wholesaler.

How do you go about deciding what CNC lathes, CNC machining centres and CNC milling machines you will supply and support? What are your selection criteria?

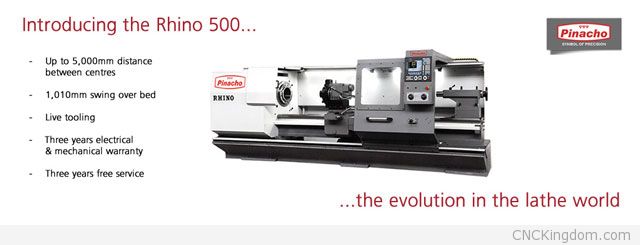

They have to be very strong and high precision machines but at a very competitive price as well as being custom built to the customers specifications. Many customers have their specific requirements – just recently we have had a lathe completely customised for use left handed!

How do you go about deciding the value of used CNC machinery?

There are so many different factors that are involved with value from usage and quantity in the market to location and demand… how do you know you are getting something that is still good? The quality, cleanness, if it is working/in use, how much use it has had and also the overall current state of the machine. Also, how reliable the seller is. It needs to match the specific requirements of the requesting customer.

How important is tooling to your overall business? How often are you tasked to do retrofits? Can you give some examples of work Direct CNC has done in the past?

Very, it has to be strong, hard wearing and accurate. We do retro fits quite often, we work in countries like Nigeria and US etc. We retro fit any kind of machine and any size.

5- What is the general lifespan of the machinery your sell new? I’d think that a machining centre and lathes can easily outlast their operator if well maintained due to the incredible strength they have.

5 years+ can last as long as you need them. They’re like a car, if it is looked after and serviced it will run forever! We do offer 3 years servicing and 3 years warranty with all new machinery and 1 year warranty and servicing with all used machinery.

How do you compete against Chinese machines that enter the UK market for a fraction of the price?

We don’t badge machines up, we deal with the manufacturers directly of the lathes. We go with the no bull, to the point service. What is the point in lying to customers? Honesty is the best policy.

How hard is it to find quality and certified employees to work at your company? CNC skills such as programming (with realworld experience) aren’t the easiest to come-by.

Like with everything, experience comes with age however younger students who have committed to the courses over the years, 9/10 of them are determined to work well in the industry and hopefully these are the ones that are willing to become the ‘pick of the bunch’ ones in the future.

Anything you’d like to add?

I think from a personal view and from what I have experienced the UK market is not as busy as foreign markets however it is slowly picking up. It has peaks and troughs however it keeps moving forward and that is the most important factor.