Noah Christie, Mechanical Engineer at Control Technologies (USA)

The job of a mechanical engineer is problem solving – whether it’s figuring-out how many gears you need to make a certain piece rotate within specified material tolerances without breaking or doing product simulation – the puzzles just keep on coming! I though it would be nice to see what a real mechanical engineer does and some of the challenges of the job and Noah was great enough to volunteer!

The job of a mechanical engineer is problem solving – whether it’s figuring-out how many gears you need to make a certain piece rotate within specified material tolerances without breaking or doing product simulation – the puzzles just keep on coming! I though it would be nice to see what a real mechanical engineer does and some of the challenges of the job and Noah was great enough to volunteer!

You can find his freelance profile at http://donanza.me/noahchristie and Control Technologies can be found at http://www.controltechnologiesllc.com.

What attracted you to engineering in the first place?

I would say that the aspect of pure problem solving was the most attractive thing to me. I actually worked with formula derivation and software writing before i did much mechanical engineering, once i figured out that the same challenges can be faced mechanically i was hooked.

What is FIRST, how did it help develop your passion for robotics and later, what made you want to continue in the program and become a mentor?

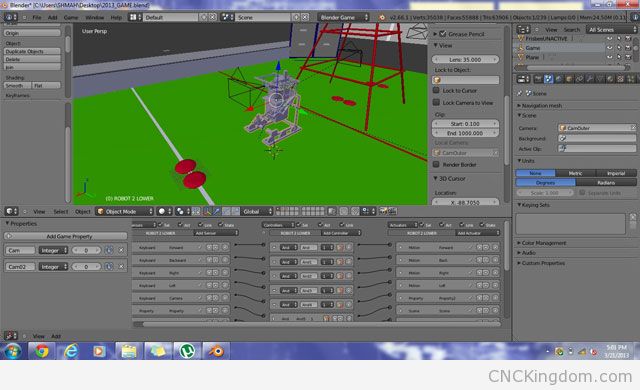

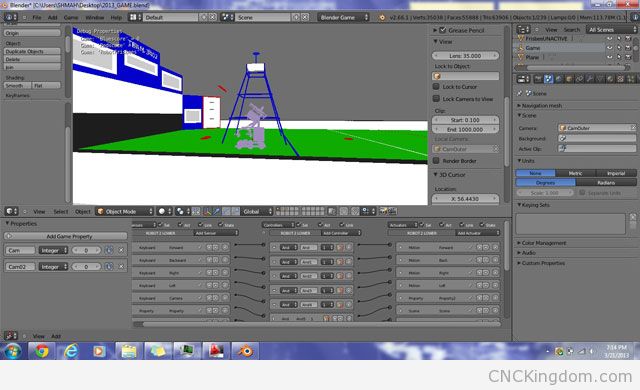

FIRST is an engineering challenge that is set forth every year with different tasks in which teams compete in randomized alliances for which they gain points for different aspects of gameplay. These challenges put together all of my interests in mechanical, electrical, and programming so it is something that i do not need to be persuaded to participate in.

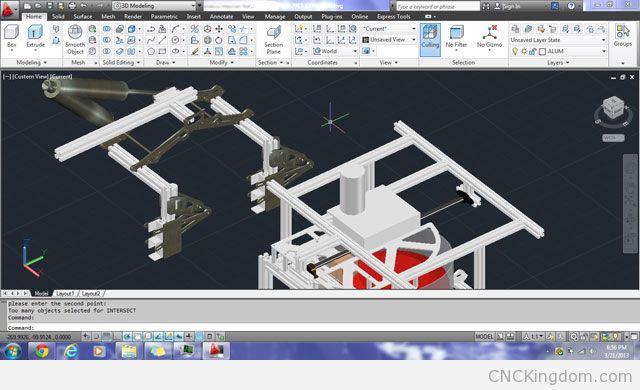

What is the typical day like for a mechanical engineer? Do you interact with other departments much at Control Technologies?

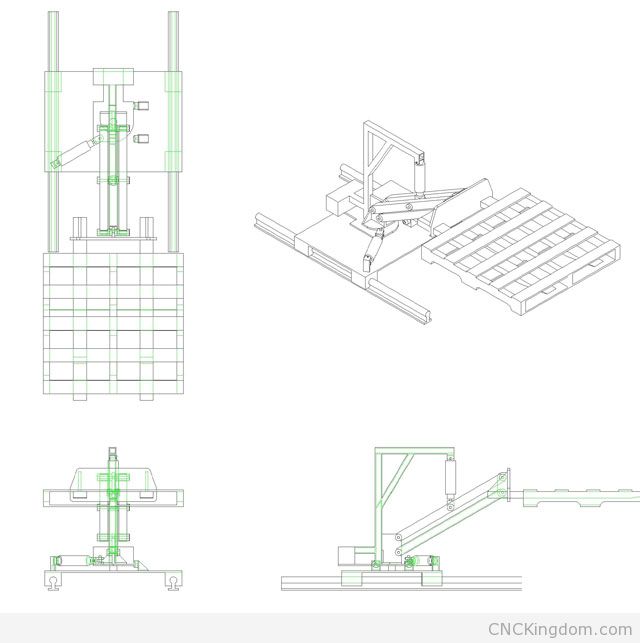

My days are usually tied between project design and interfacing with the machine shop. I interact with all of the departments of Control Technologies, customers, sales, quoting, and much more on a daily basis. Very often i am in meetings with new and existing customers to define design criteria and solutions for their situation, which may vary a great deal.

What are some common engineering mistakes you see from engineers fresh out of school and what is the easiest solution?

I see many issues with over/under tolerancing, lean design leading to failure, and inability to concept. I would recommend that graduates spend time as engineer technicians and machining to develop the ability to apply GD&T, which is only grasped by practical use. I would recommend that they learn to utilize the FEA capabilities of their software as to avoid failure from design that is too lean. The thin that helped me the most in the area of concepting was programming and formula derivation, as they are not straightforward and require heavy concepting.

What is different between freelancing as an engineer and working in a company as an engineer?

Freelancing usually eats up much more free time. It is easier to work through a company, however you are not limited to just your job description and usually provides great opportunities to learn new skills.

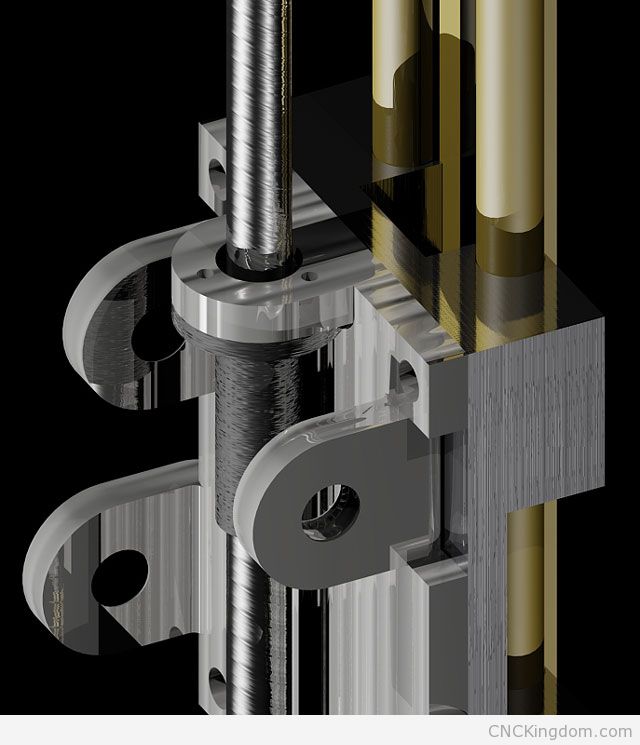

What are some of the tools of the trade that you couldn’t live without, hardware and/or software? What was the learning curve like before you became comfortable using them?

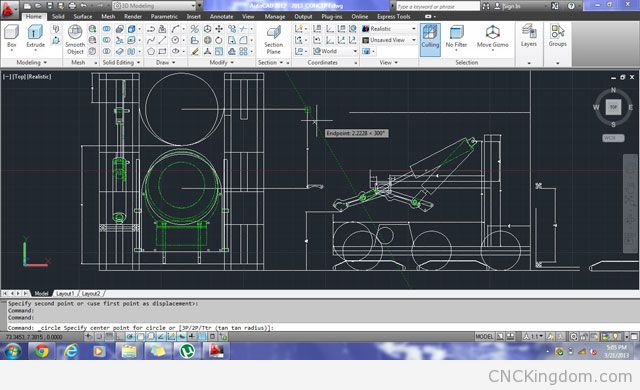

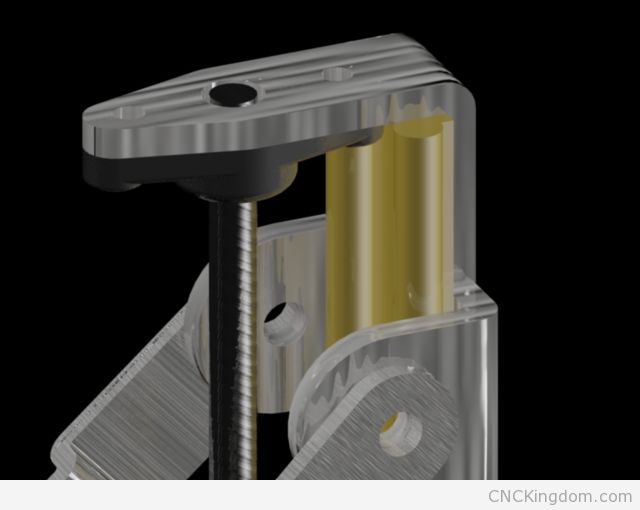

Definitely my solid modeling software. I actually picked up AutoCAD and Inventor as an easier alternative to MS paint (believe it or not) which i was using to produce my concepts and prints for parts i would make myself. My first version was AutoCAD Mechanical 2004 and Inventor 8.

What advice would you have for somebody interested in following your engineering path? Was there anything that was a big surprise to you or something that would have saved you from a lot of grief?

My advise is to never stop researching and learning about everything that crosses your path. The sheer amount and intricacies of technology that i know nothing about continues to surprise and intrigue me.

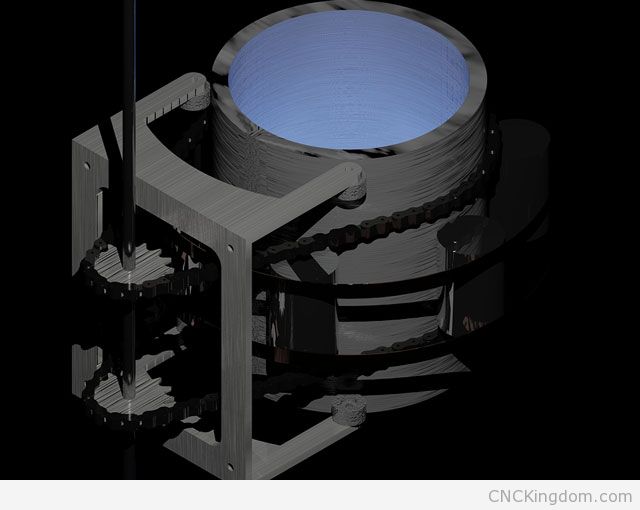

Unlike many engineers, you are also very much a humanitarian. How did you first get involved with these agencies and causes and what are some projects you’ve done that have helped them?

What started my passion for humanitarian causes was a Unicef commercial requesting financial aid. I realized that i could not afford to support their cause monetarily and asked myself what i could do to improve suffering in the world. I realized that i could use my passion for engineering to solve these daunting problems that plague our world with hunger, disease, and poverty. I have put much of my time into well laid concepts for greenhouses, water purification, energy, manufacturing, disaster relief, medical, and am always looking to take on more.

Anything else you’d like to add?

I would like to add that I appreciate your consideration and hope to be beneficial to your work.

You can find his freelance profile at http://donanza.me/noahchristie and Control Technologies can be found at http://www.controltechnologiesllc.com.