Mike Dean: Owner of Epilog Laser (USA)

I’m in a slightly unique position with CNCKing.com where I have been talking with CNC laser owners around the world with just about every brand of CNC laser in the market for the past 7 years. Although there is a lot of play when it comes towards purchasing a CNC laser, from the market segment you hope to serve, where you are based, applications and budget you are contending with, Epilog Laser is a name that keeps coming up over and over again.

I’ve been following Epilog Laser for almost a decade and have had the pleasure to talk to a number of their customers, sales reps and staff through the years. Mike has played a pivotal role in the CNC laser industry to turn niche machinery into mainstream thought his enthusiasm, drive and desire to get innovative new technologies to market.

You can visit Epilog Laser at their website https://www.EpilogLaser.com.

You co-founded Epilog Laser almost 23 years ago, did you think back then that Epilog Laser would become one of the world’s largest manufacturer of small and medium sized CO2 and fiber laser systems? What encouraged you to want to jump into the industry back then and how as the ride been thus far?

When we got started we had a business plan that showed if we could sell five machines a month we would be on top of the world! We knew here was a market, but we really underestimated its size and scope so, no, we had no idea what was to come.

When we got started we had a business plan that showed if we could sell five machines a month we would be on top of the world! We knew here was a market, but we really underestimated its size and scope so, no, we had no idea what was to come.

The reason we started the business was that we were young, entrepreneurial, and thought it would be fun to start our own business.

I had worked with one of my partners – Steve – at a different manufacturing company and we had similar business philosophies that were at odds with the people we were working with at the time. We thought it would be great if we could be in charge and run a company the way we wanted to run it.

The ride so far has been great! We work with so many good people and it’s been so interesting that it’s sometimes surreal to look back at Epilog’s progress. I tell people that I’m so lucky that I knock on wood so often that my knuckles are raw!

There are many CNC manufacturers that have branched out into other CNC technologies as they’ve grown through the years such as Plasma, Router etc. but Epilog has always been a CNC laser company. There is a certain amount of synergy across CNC machines and their related customer bases where this can be seen as a very profitable progression. Have you ever considered expanding your offerings into other CNC machine types though the years?

We see the synergy with other types of CNC machines, but we’ve never wanted to manufacture anything other than lasers. There are so many opportunities in the laser market that we don’t feel the need to branch out.

Every different type of machine requires its own level of expertise and while there are similarities between CNC machines they all have their own secrets that you need to know to make them great. We feel like we would be diluting our laser efforts if we had to learn the secrets of how to make a really good CNC router or plasma machine.

The 3D printing space is a rapidly evolving ecosystem where the prices of the machines keep dropping while their functionality keeps rising. Why haven’t we seen that in the CNC laser industry? If anything, it seems like quality CNC lasers keep going up in price as their functionality increases!

Relative to the laser industry 3D printing is a well understood and simple technology that many, many people understand. I always tell people that producing a laser requires a certain amount of black magic and you can sense that it’s difficult just by looking at the very small number of companies that manufacture laser tubes. If it were easy everyone would do it.

What are some of the programs and methodologies that Epilog Laser employs to improve the ROI of customers buying your CNC lasers? What technologies have you built into your lasers that help improve the bottom line of your customers over the long term?

In your earlier question you asked about rising prices. Many of our customers see a greatly improved ROI because prices have actually come down dramatically. When we started we sold a 25 watt laser system for $18,000. We sell a more powerful system today for less than $8,000.

Additionally, speed increases have allowed for much higher throughput and ease of use improvements have reduced the training it takes to operate a laser. They are now so easy to operate that Epilog manufactures the only laser system that is operated by the consumer at your local PetSmart store.

You recently came-out with your Fusion line of CNC lasers, it seems like a natural progression from your Zings to Legend series. How long had the Fusion been in development and how did you pick and choose what you wanted in this new platform to both make it standout in the marketplace yet affordable for people to purchase?

I really like the direction Epilog Laser took with this new platform btw. The Fusion was in development for several years and we choose the Fusion path by listening to our customers.

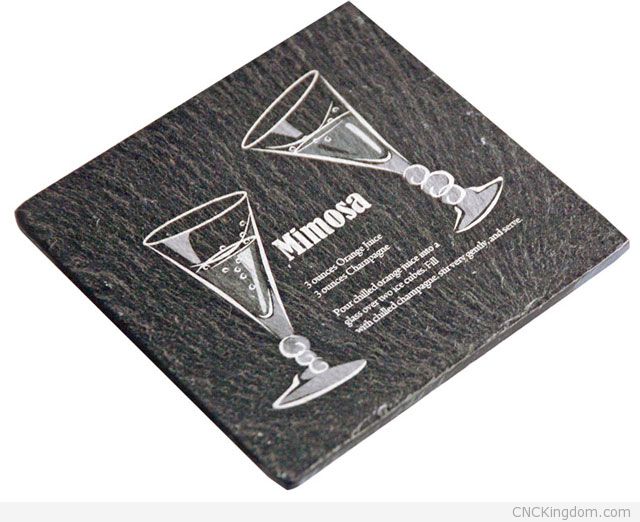

Epilog has a lot of loyal customers and they really liked their earlier machines like the Legend series, but they wanted bigger, better, faster so we tried to accommodate what they requested. The Fusion 40 is our biggest machine at 40″ x 28″, it has a lot of user features like the Job Manager, and it produces a better product.

I would like to say that we were responsible for the Fusion design, but mostly we listened to our customers and tried to give them what they asked for.

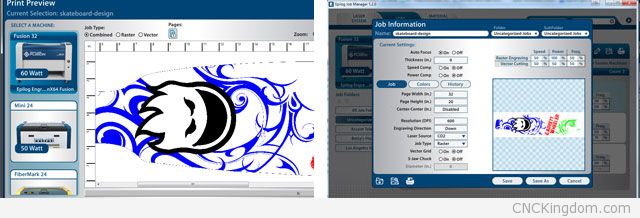

We all know that software is as important, if not more important, to a CNC machine’s overall functionality and ROI than the hardware. What are some aspects of Epilog’s job control software that allow an operator to both get up to speed FAST on an Epilog and turn a good profit?

The Job Manager saves every aspect of every laser job you print to the laser. This allows users to go back to previous jobs and repeat them without having to think about what they did or how they did it.

We have lasers in our production area that run the same jobs over and over. When we gave the Job Manager to the operators one of them said “It’s the best thing since the invention of the laser!” It made their daily lives so much easier.

We have a great group of software engineers that really understand the user experience and they developed the Job Manager for our customers, not for themselves.

Every laser operator has their favorite materials and applications for their laser – what are yours? I love working with wood… are you an acrylic, wood or metal guy? Why?

I love working with wood and cutting acrylic. My family thinks I’m nuts, but when we’re out together I’m always able to find laser engraved wood products and I point them out. I usually take photos of what I find and I have probably hundreds of photos of laser engraved wood products that I’ve discovered over the years. I don’t know why, but I’m just intrigued by what people have done with wood and their lasers.

I love acrylic because it’s easy to incorporate color into the laser process. There are dozens of acrylic colors available and making signs and acrylic structures with different colors is a great creative outlet for me. I made a backdrop out of colored acrylic pieces for a wedding that people loved! Nobody knew what it was, how it was made, or who made it, but I heard many very positive comments on it.

The CNC industry has changed tremendously over the past few decades, they are easier to work with, more mechanically sound and their software… well, I don’t even need to know G-Code to design things! How do you see the industry evolving over the next few decades and what role does Epilog see itself playing in growing the CNC laser industry?

I wish we had unlimited resources. We have so many ideas that we want to develop it will keep us busy for decades. You’re going to see more power at lower prices, much higher speeds, and especially the ability to easily process many more materials.

Some of this is happening now, but it takes time to properly develop difficult technologies. I’ve been asked many times over the year whether I think the laser market is getting saturated. I say “Not even close!” It’s a great business to be in and we continue to grow every year for many years. To give you an example, earlier this year we tripled the size of our cleanroom production area and it’s already maxed it out. We’re excited!

For additional reading, I interviewed James Stanaway, Epilog’s Director of Marketing a year and a half ago (who I actually had the pleasure of finally meeting at NY Maker Faire a few weeks back) on CNCKing.com’s blog which is also an interesting insight into the company. Be sure to check it out too!

http://cncking.com/interview-with-james-stanaway-epilog-director-of-marketing/