Laser Engraving is FUN!

I’m in between several consecutive projects for other people at the moment so decided to take a breather and design my own thing again – this time tackle laser engraving!

Challenge #1: Interlocking Parts

Though I’ve been designing now for several years, I remember it took me a solid YEAR before I was able to successfully visualize and “easily” build interlocking models with very few errors in the files. The challenge is endless with interlocking parts because all the parts must meet EXACTLY for everything to work. One piece is off and the rest goes to hell pretty quickly.

Challenge #2: Complex Interlocking Parts

The next step for me design wise was building models with hundreds of pieces that were a decent size AND were actually capable of being built in the real world. Making models with up to 50 parts is easy, but once you get into the 200+ range… the amount of testing required much less the assembly and instructions becomes daunting. Add in spinning, rotating, clearances and other headaches and you soon find-out that what was once fun requires a few breaks to maintain sanity to see the project through!

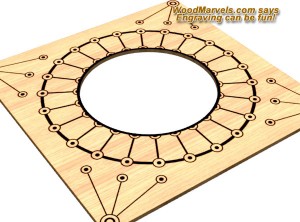

Challenge #3: Laser Engraving

I tried this over a year ago, it was tough… and haven’t touched it since. It wasn’t that the engraving detail itself was difficult, it was being able to create it visually that took lots of time. Engraving for the sake of engraving is worthless… if it doesn’t add anything to the model, save yourself the time and production costs! I finally gave myself a project where the model looks and functions great without engraving and now, I’m adding it to make it all the cooler. Engraving interlocking parts means some pieces need it, some don’t… depending on what is shown to the eye or not. Challenging but also great fun… as I’ve found out today!

Challenge #4: Laser Engraving with over a thousand parts

I’d like to design, time permitting, a model that has over a thousand parts and with integrated engraving… the model would be ridiculous to produce (costs of production much less time to assemble) but would be also fun! I have a few ideas for models that could help me achieve this on a grand scale… either I lock myself in a room for a month or two or wait till I’m retired – which ever comes first.

Challenge #5: Dynamic models

Next stop after the 1K parts count with engraving is creating dynamic models, all out of wood… something that can be “people powered” and 100% made out of wood… think of a car with bicycle pedals or a boat with a hand powered propeller and you get the idea. I’d also like to get into a mixture of wooden and 3d printed metal somehow… it’s just a matter of time.

The Bottom Line

As you can see, the challenge of creating 3D marvels out of 2D wood never really ends.