Laser Cutting & Assembly of Platform Crane B

This is the second time I’ve built my Platform Crane B at CNCKing.com, the first was with my ShopBot Desktop (both videos at bottom) and this time around, with my Trotec Speedy 400 flexx. It’s interesting to see how different the two approaches are cutting and construction wise for essentially the same identical model!

Unlike CNC routers, there is no need to hold anything down as the laser isn’t actually touching anything, it’s just energy without any force other than the gas and extraction that I have hooked-up. You don’t have smoke with a CNC router… so it’s a give and take.

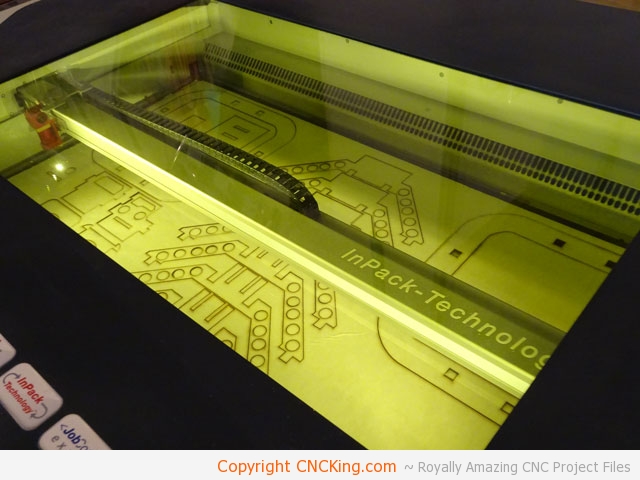

Unlike my ShopBot Desktop, I’m able to easily cut everything on one sheet of plywood though I do have to cover it so I don’t end-up with smoke stains along the cut lines.

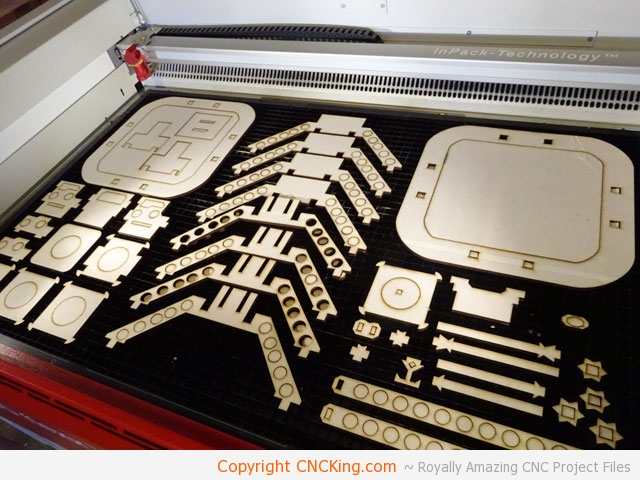

Favorite part of the whole process is when I can do this – just lifting the scrap off leaving the import parts for this Platform Crane! There is still a lot of work yet to be done, laser cutting is the easy part, even easier than the initial designing process… now it’s time to build the model!

Yep, all those extra clamps I have now really do come in handy – I can glue so much more of the model together in one shot! I let things dry 24 hours though I could easily take the clamps off a few hours later, I find the glue on the inside parts where there is little air circulation take longer. I have plenty of other things to do so this wait isn’t a big deal. I’m in no rush.

And voila, the fully glued together bottom part of the Platform Crane. The CNC laser model is smaller than the CNC router version so I didn’t need to use my larger bar clamps to hold things together but the results are just as good. Very solid foundations make for wonderful models when you have stuff on top moving around.

Next step was the top part, again, I was able to do this in one shot and let it dry 24 hours… the entire process of building this model is less than a hour of work spread across two days. I design my models to be incredibly easy to put together with as few pieces as possible… I hate assembling models that have hundreds of identical looking parts and based on sales on CNCKing.com, customers feel the same way.

And that’s how you cut and build a CNC laser Platform Crane. You can get this CNCKing.com model in two versions, one optimized for CNC routers and the other for CNC lasers – you can cut the CNC router version using your laser but no the other way around unless you use a crazy small bit… hence why I made the router version larger!

Watch the video of both versions being cut and built below.

And now the CNC router version a few years ago.