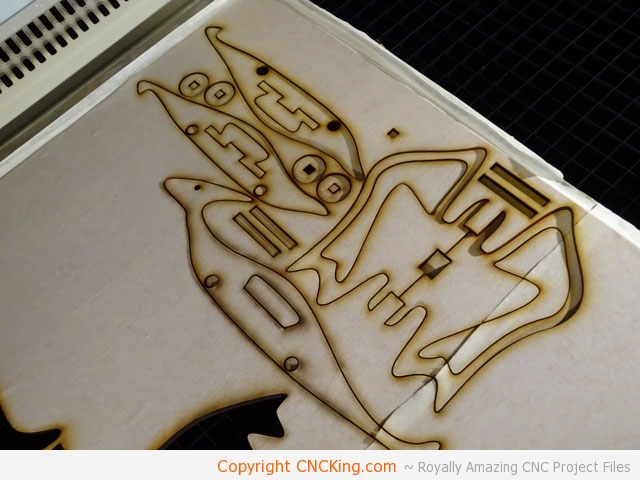

Laser Cutting a 5 mm Plywood Pterodactyl

After making a few “flat” dinosaurs, I decided to try things at different angles and that’s how the original Pterodactyl came about here on CNCKing.com.

The challenge that came about in this model was clamping as I didn’t make interlocking parts go all the way through the model, the middle just “hangs” there while the two sides are glued to it and within those, are the supports for the wings. It works!

The cutting process went smooth as expected – you know how many errors I’ve had with my Trotec Speedy 400 flexx while cutting? ZERO. I’ve had no stepper motor problems, I’ve had no com errors and my laptop has other programs running while cutting – a big no-no.

I have Skype running, doing design updates in Corel, surfing the web and playing music in iTunes. ZERO errors – I swear my laptop is more stable when cutting things on the Trotec than when it isn’t connected to it! I’m not saying you should do the same – I advise you to follow their advice using a dedicated computer, but my Trotec Laser is more stable than my laser printer! About the only thing I haven’t done while running a cutting or engraving session in JobControlX is 3D rendering and that’s because I prefer to do this on my dedicated industrial workstation.

I had serious doubts about masking, those doubts are gone – it’s awesome! I save so much time using this! Sure, my sander is slowly building-up a layer of dust over it but you really can’t beat the efficiency of this material. I love it and want to wrap everything I stick in the laser with it!

Yep, another model down… time to try some things with different materials and a higher level of complexity next week. I’ve been using my grid table for cutting wood projects but when it comes to acrylic, time to pull it out and put in my professional cutting table which should dramatically reduce flashbacks. Perfect for acrylic! Watch the video!

You can of course find this model and a whole bunch more over at CNCKing.com – all these dinosaurs are found under the “It’s Alive” sub-heading (CNC laser / CNC router).