Ka Wai Ng, Industrial, Mechanical & Product Design Engineer (Singapore)

Ka Wai is probably the closest I’ve found in the design world that mixes two distinct yet mutually beneficial hats in his design and build process – having both a degree in mechanical engineering and industrial & product design. It’s such an awesome combination and very much the same approach I take towards my own designing – a mixing esthetics with precision.

Key takeaways from this interview include:

- engineering and design are 2 industries that can complement each other… engineering tend to be more quantitative and “logical”, while design is more qualitative and “creative”.

- I always want to design a product that could have different functions based on the need of users.

- Ka Wai is also a fan of slotted designs!

You can view Ka Wai’s portfolio at http://www.coroflot.com/wai/portfolio.

After studying for four years in Mechanical Engineering from the National University of Singapore, you jumped right into another bachelors at the Hong Kong Polytechnic University for industrial and product design. How similar or different were the courses themselves and approaches to designing between the two universities?

Before I enrolled in the Industrial and Product Design course, I had over a year experience in a Singapore based engineering design company working as a automotive design engineer. Since young I was very interested in design, and I thought that if I really intend to start my dream career in the field of design, a proper education in the basic skill set of the design industry is crucial. Hence I went for a Bachelor Degree course in Hong Kong Polytechnic University.

Before I enrolled in the Industrial and Product Design course, I had over a year experience in a Singapore based engineering design company working as a automotive design engineer. Since young I was very interested in design, and I thought that if I really intend to start my dream career in the field of design, a proper education in the basic skill set of the design industry is crucial. Hence I went for a Bachelor Degree course in Hong Kong Polytechnic University.

To me I feel that engineering and design are 2 industries that can complement each other. Although their approach to design can be very different in some ways, engineering tend to be more quantitative and “logical”, while design is more qualitative and “creative”.

I remember when I was designing mechanical components in my engineering days, the key words in mind were light weight, strength, stress, tolerance, etc. Hence its form is truly based on quantitative factors. While in design, the approach to the same product can be from a totally different perspective, we might look into the aspects such as feel, culture and perceptions, the softer and not so quantifiable factors. I am glad that I have experienced the 2 very different design approaches and now I can apply a hybrid version in my design works.

You’ve taken a number of internships and worked for several design firms since enrolling and graduating from the Hong Kong Polytechnic University in 2011. What have you learned in these positions and how different is it working on academic assignments vs real world industrial design projects?

All internship positions gave me the feel of how the design field works in real life. I had the opportunities to participate in many project meetings and involve in ongoing projects with fellow colleagues. While academic assignments tend to be more conceptual in nature, real world industrial projects are more complex which involves factors such as cost of production, tight schedule, etc.

I really like your 1PC Plywood Chair, I think it’s an awesome concept and plywood is such a great material to work with generally due to it’s incredible material strength and flexibility. I was wondering where the concept came from and if you ever thought of building it in real life? It doesn’t look like the simplest of projects to buid due to the complex molding required.

I was thinking about the possibility of looping plywood into a continuous piece while giving it a soft and classic feel, hence the shape of 1PC came naturally.

I would really want to build it in real life, however, the intricate shape of the chair required highly skilled and consistent wood molding experts and I am currently still looking for a suitable partner to realize this project.

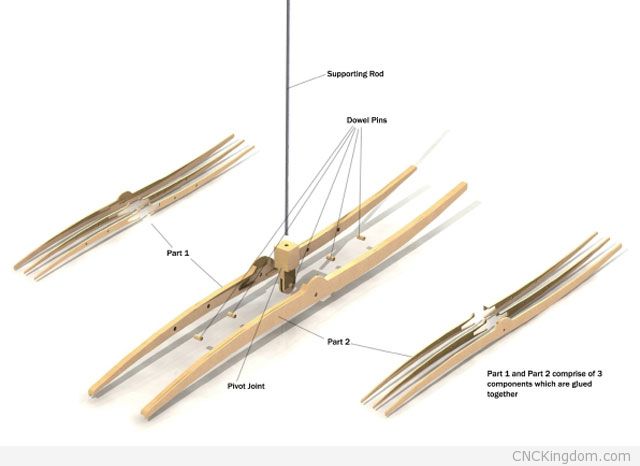

The modulability of your Monocart is fantastic, I can see this useful in so many applications especially with how it’s built to be easily interchangeable depending on the application. What were some of the challenges coming-up with the design and where did the idea come from?

I always want to design a product that could have different functions based on the need of users. It would be interesting if a product could have different “lives” that allows people in different life stages to use it. Intensive research was done to identify a type of product that could apply this idea of modular design for different types of users, and I found that wheeled carts are a very good candidate for this concept.

Since this concept involves users of different age groups, to determine a shape and mechanism that can transform into different functions easily was a challenge. Hence I have to put on different “hats” during the design phase, exchanging between my engineering experience with the design sense when designing the mechanism and styling of Monocart.

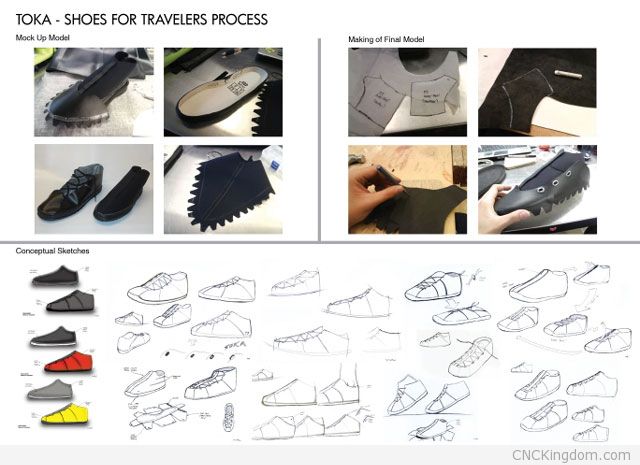

You tried your skills designing a unique shoe concept with your Toka, what are some fo the challenges present that you found with designing footwear and how long did it take you from design to finished wearable prototype?

Toka shoe design was part of my multi-functional design experiment during my design study (it was about the same time when I was working on Monocart). Its a shoe in shoe concept that allows travelers to wear different shoes while having less luggage to carry.

It was quite a challenge during the design phase as to decide the material choice and construction method for the inner and outer shoes where comfort and ergonomics are the top priority. The whole project last about 2 months from initial sketches to final prototype.

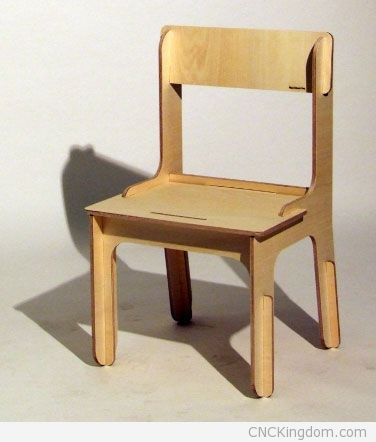

I’ve built over 200 flat-packed models – mostly toys with CNCKing.com… I haven’t gotten into furniture yet but I do very much plan to get into that market shortly. I like the design you have for your Flat Pack Chair (FPC) and was wondering how long it took you to design and prototype this chair? I’m a big fan of slotted designing as I build my projects without any hardware being required… did you come-up with any challenges while designing this project?

I am also a fan of slotted flat pack products. Since I was doing it during my free time, it took me a few days to work out the construction aspect of the chair.

I am also a fan of slotted flat pack products. Since I was doing it during my free time, it took me a few days to work out the construction aspect of the chair.

For the first prototype, I hand cut, touch up and assemble the boards to test out the strength and work-ability of the chair. Subsequent prototypes were done using CNC router.

I always love solving puzzle problems so the design process was an enjoyable one and there was not much issues at all.