Jerry Kavanagh, MD of CiNCh Software (Ireland)

CiNCh Software promises to revolutionize the industry with a term coined by Jerry, Smart-Metrics. It has all the benefits of parametric modeling without the headaches! His company, focused on a Joinery Production system for the woodworking industry which will communicate with all existing CNC based technologies out there!

You can visit Cinch Software at http://cinchcam.com.

How did you end-up in the CNC industry to begin with and then jump into software development for woodworking?

My background is I studied Furniture Production Technology at college and I worked as an in-house technical project manager for a high profile joinery company in Ireland. One of the projects I managed for them involved the moving of their current manual staircase manufacturing from manual processes to automated production on a 5-axis CNC.

My background is I studied Furniture Production Technology at college and I worked as an in-house technical project manager for a high profile joinery company in Ireland. One of the projects I managed for them involved the moving of their current manual staircase manufacturing from manual processes to automated production on a 5-axis CNC.

We had purchased an extremely expensive staircase manufacturing package which was the biggest mistake the company made. After 6 months of torture and no stairs off our £275,000 machine I had to begin developing in-house parametric programs to get us up and running. So I guess the answer to your question is I was forced, but willingly I was very interested in this new technology.

You spent many years consulting (JK Solutions) woodworking companies in both software and hardware solutions to increase the efficiency of their operation and of the people working at them. What are some of the biggest time and money sinks that many operations had that represented the biggest ROI of your services?

The biggest mistake most companies make is not managing their costs. Particularly where a company has a lot of traction and grows fast most of the pricing is done using manual systems and a lot of guess work is involved. This is the biggest danger however in an competitive climate like the one we are now experiencing. If you do not know where your bottom line is, it’s very easy to cut your own throat.

When it comes to CNC the biggest mistake that everyone makes is not understanding the limits of the machine. What I mean is, not the limits of what the machine is capable of, but to understand these 4 limits.

- The machine is only as good as the operator controlling it!

- The skill of the guy controlling the machine is directly related to the skill of the guy who trained him!

- The machine is only as capable as the software that is driving it!

- And finally the software is only as good as the guy who set it up!

Everyone expects that when they buy a CNC the can immediately do anything, but this is simply not the case.

A few years ago you got into software development, we talked a bit about parametrics and you told me you had a new revolutionary approach to woodworking called Smart-Metric. What is it, how is much better is it and why do I want to use this approach?

Good question. Parametric’s have always annoyed me. Why do they have to be so bloody complicated? Why do you have to be a brain surgeon to create even the simplest versions of these programs? The answer to these questions is simple; “Lazy software developers”. It’s very easy to create the functionality to allow a user to develop the type of parametric programs we are used to, however, making this intelligent now that’s a different story.

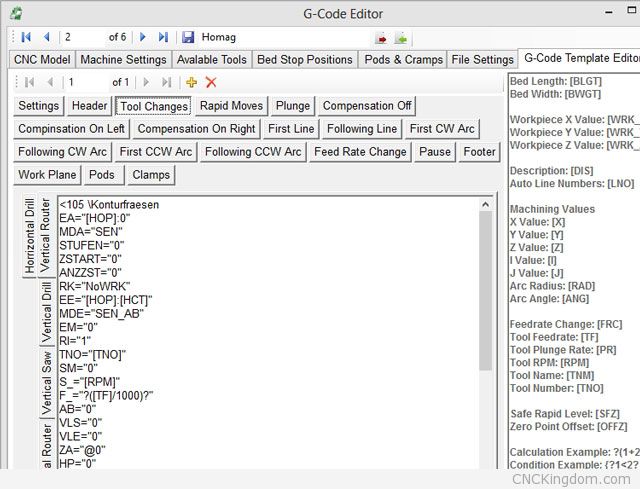

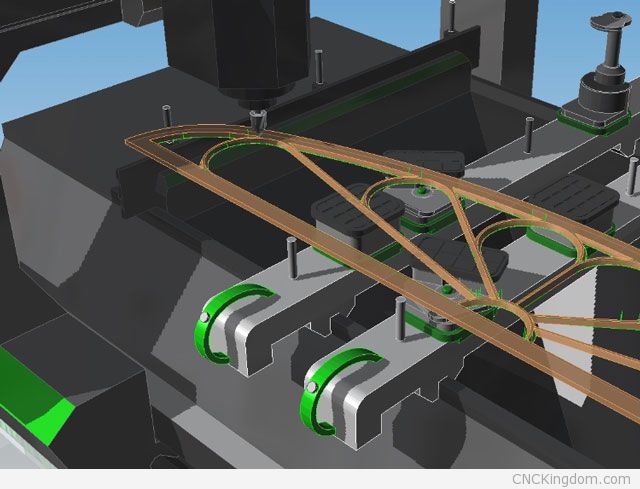

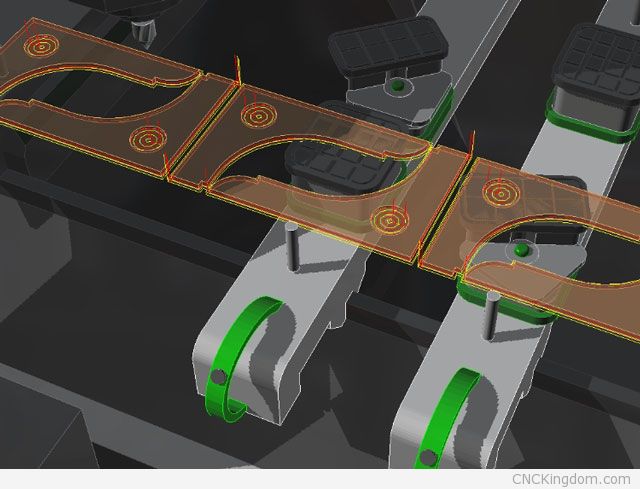

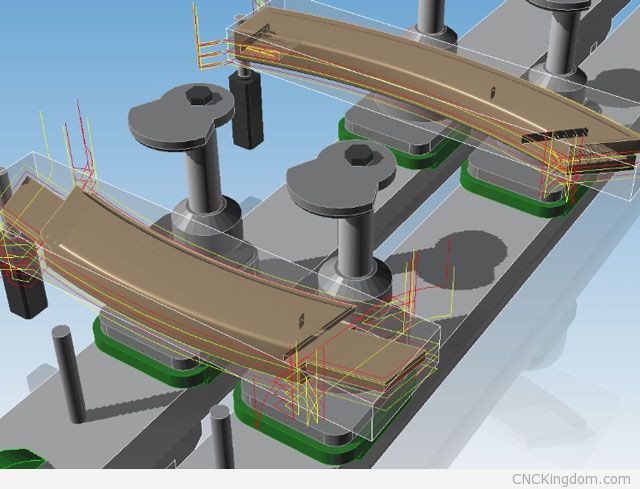

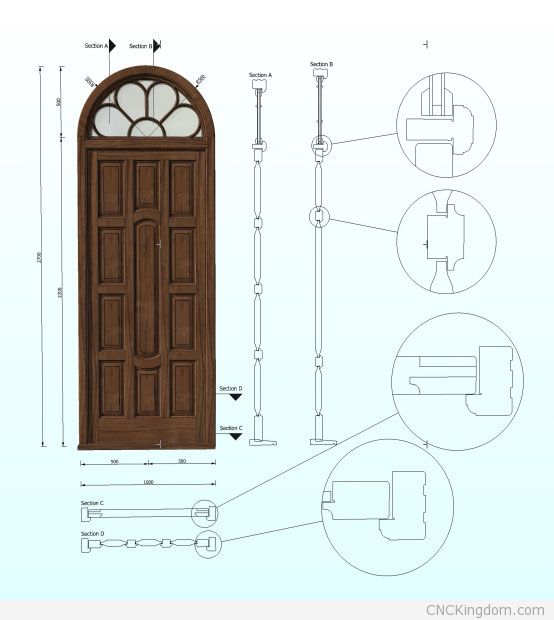

I have coined a term called Smart-Metrics. This is a top down solution to this problem. Instead of creating a completely parametric program the user creates parametric programs automatically. This is because there is parametric intelligence built into all the machining algorithms, and these paths are applied to smart objects, the result of which is that any of these objects can be dynamically resized and all the tool paths are regenerated automatically.

Now there are versions of this in certain programs however not to this level. We have taken this a step further also in that not only can the user stare from our extensive library of smart objects but he can create his own objects within the software starting with simple CAD drawings.

You offer a host of software solutions from joinery to CAM, what aspects of these software offerings makes your customers speechless when they realize the solution you are offering them?

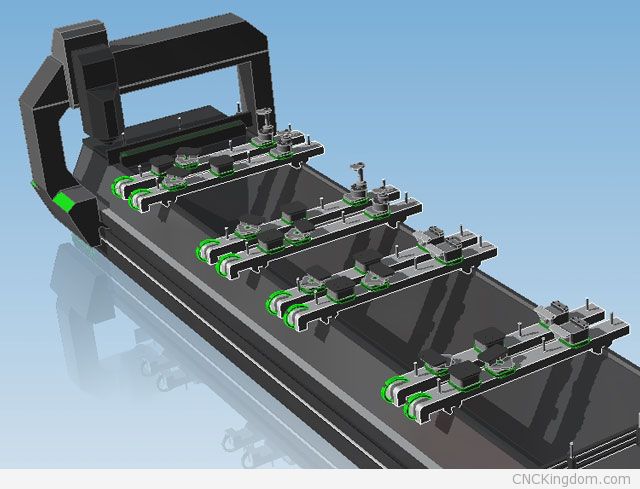

The biggest and always the most influential aspect when presenting to a client is visualisation. If a client can visualise final designs, or can even see a machine move it has a great impact. The second most influential aspect of any software and should always be the most aspirational thing a developer should do is: ease of use, and speed. If a client can visualise that something is going to give him any of these results (preferably all) you are on to a winner;

- Reduce his costs.

- Speed up production.

- Reduce his workload.

- Increase his satisfaction.

With CiNCh I have tried to ensure high delivery in all these areas.

There are many software solutions put out by CNC manufacturers that are given to their customers, why should they put out some extra money for your solutions? What niche are you filling and do you think it’s only a matter of time before these companies begin investing more heavily in your space?

True there are many options for CNC software, however my offerings are more than just CAD CAM packages. These packages are designed as ERP (Enterprise Resource Planning) type solutions.

We aim not only to allow you to create CNC programs efficiently but to enable you to manage your business while increasing your revenue. We also provide the skills to enable you to create this change within your company.

How do you handle customers who want more and more specialized features than your software provides? Do you also offer custom software augmentation services to help them with their specific needs? Will you be offering localized versions of your software in other languages than English?

This is inevitable, only an idiot thinks that they have all the answers immediately. We work closely with all our clients requirements and when necessary can adapt the product or included new features.

Our products have been developed working closely with some very specialised companies, particularly selected because everything they manufactured was off-standard. This gives us an excellent starting point, however we are not arrogant, we don’t pretend to have all the answers. We aim to make the products as dynamic as possibly, but welcome the fact that continuous improvement is an ethos that should always be embraced.

Simple answer to this question; All of them!