Jeff Fay, President/Owner of Pioneer Valley Engineering (USA)

Jeff started Pioneer Valley Engineering by downsizing his personal life to be able to up-size his future potential by running his own engineering and production business. In hindsight, it was the best decision he ever made! Here’s a few takeaways:

- Nothing beats on-the-floor experience.

- Accuracy and quality must supersede speed to keep customers happy even under time pressures.

- Run a LEAN business so more time is spent working, not shuffling paper.

You can visit Pioneer Valley Engineering at http://pioneervalleyengineering.com.

How well did your Mechanical Engineering degree from Springfield Technical Community College and your Bachelors degree in Engineering help you in your career thus far? Was what you learned relevant or filled with fluff that you quickly forgot when you joined the real world?

Both my degree from STCC and my bachelor’s degree were not very beneficial to my career. In the engineering and manufacturing world, and the situations that come with it, are not something you can read about in a book, or be taught by a teacher standing in front of 30-100 people. Everything I have learned has been from experience on the job, tips and tricks from guys in the engineering and quality departments and most of all, from the guys standing at the machine on the shop floor.

Both my degree from STCC and my bachelor’s degree were not very beneficial to my career. In the engineering and manufacturing world, and the situations that come with it, are not something you can read about in a book, or be taught by a teacher standing in front of 30-100 people. Everything I have learned has been from experience on the job, tips and tricks from guys in the engineering and quality departments and most of all, from the guys standing at the machine on the shop floor.

You spent many years working for other companies before jumping ship and starting your own engineering company, Pioneer Valley Engineering. How easy or difficult of a decision was this and how did thing turn-out?

Starting my business was not a tough decision. I know I had the knowledge and motivation to move on from working for “the man” and start working for myself. With that said, starting my business full time was the toughest decision of my life. With a wife and three kids, two houses, and more school loans than I know what to do with, it was the biggest decision of my life, but I took precautions (sold my house and downsized, paid off car loans, and minimized the debt we were in) to make the plunge, and it turned out to be the best decision for me and my family.

There is a tremendous amount of outsourcing going on today but manufacturing is one that’s been especially hit hard over the years. When I first started my 3D industrial animation business almost 15 years ago, at first companies outsourced their molds and prototyping, then their manufacturing followed by their engineering staff. How do you compete and stay in business with such incredible competition that’s now just an e-mail away for most firms?

Quality and lead time. At Pioneer Valley Engineering, we make sure we get the job done quickly and accurately, and I, as the owner of the company, take it personally when we fail to do so. If you keep your customers happy, they will begin to trust you, and not hesitate to send you more work.

Pioneer Valley Engineering offers a host of engineering services. How do you find most of your clients and what types of services are especially popular with your firm?

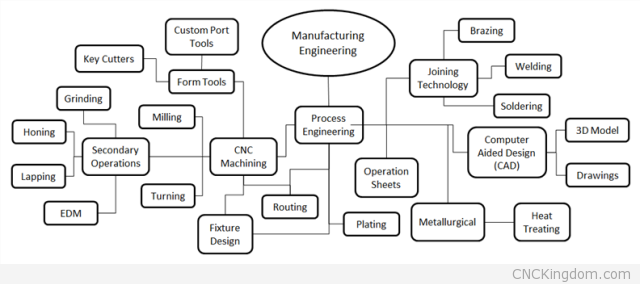

I don’t like to be the “typical salesman” and cold call companies or just pop into their business and expect them to give me the time of day. I take a more passive approach, by either writing a short quick email introducing myself and my company, or send a flyer in the mail with a list outlining the services we offer. The top services we offer, is process engineering with operation sheets and a process outline, and fixture design.

How have just-in-time delivery and manufacturing processes affected the expectations placed on your firm? Do clients want things faster and faster for increasingly demanding production cycles or are they willing to wait for quality work?

In this industry quality is king. I get pressured, just like everyone does, in this industry, but in the end, I believe all companies would prefer quality work, over inaccurate work, due to rushing.

What are some tricks that you use to streamline the manufacturing process of your customer’s parts that save both on production time and money?

I stress more than anything for my employees to be organized, and work efficiently. From what I’ve seen in my years working for other companies, is that the guys who have piles and piles or paper on their desk spend more time shuffling paper than they do actually working on a project. We have kickoff meetings for every project that we get, and then I assign them to a group of guys consisting of anywhere from 2-4 guys depending on complexity.