Interview with Sara Hee of Guangzhou Sino Achieve Mechanical Equipment (China)

I caught-up with Sara a few days ago and told her I’d love to interview her on behalf of Guangzhou Sino Achieve Mechanical Equipment and thankfully she agreed. I asked her to reply to my questions in both English and Chinese as CNCKingdom.com is focused on the international CNC marketplace. You can find Guangzhou Sino Achieve Mechanical Equipment online at gzsamew.com.

What is a waterjet cutting and why is it important for industrial companies? Why do you need to use abrasives with water cutting?

Water jet cutting is high pressure water jet generator platform with a combination of two-dimensional CNC machining a plane cutting machine tools. It will flow pressure increases to a sufficiently high (200MPa or more), the water with great kinetic energy can penetrate the fiber, wood, leather, rubber, etc., in a high percentage of water in the mixing abrasive, can penetrate virtually all hard materials such as ceramic, stone, glass, metals, alloys, etc.. CNC machining platform in two dimensions under the guidance of the material processed at any position or end processing, by setting the track moves at a speed appropriate to achieve arbitrary graphics plane cutting.

With the traditional “hot” compared to the cutting process, high pressure water jet cutting machine to cut the flow of media, is a “cold” cutting process. It has the following features and benefits:

- cutting without thermal deformation of the material to avoid physical and chemical changes;

- widely adapted to a variety of materials cutting, there are “universal cutter” reputation;

- cut smooth burr, generally without further processing;

- manipulated by the CNC system, high precision cutting;

- kerf less than 1.2mm, easy nesting cut, saving material;

- process does not produce polluting waste.

CNC water jet for those using other methods difficult to cut materials such as Kevlar (Kevler), titanium alloys and various composite materials are ideal or sole means of processing.

Adding garnet abrasives, the mass flow increases, the speed the greater the kinetic energy of the water, at a flow rate under the same circumstances the greater the ability of external work, thus greatly improve the cutting ability.

水射流切割是将超高压水射流发生器与二维数控加工平台组合而成的一种平面切割机床。它将水流的压力提升到足够高(200MPa以上),使水流具有极大的动能,可以穿透化纤、木材、皮革、橡胶等,在高速水流中混合一定比例的磨料,则可以穿透几乎所有坚硬材料如陶瓷、石材、玻璃、金属、合金等。在二维数控加工平台的引导下,在材料的任意位置开始加工或结束加工,按设定的轨迹以适当的速度移动,实现任意图形的平面切割加工。

与传统的“热”切割工艺相比,超高压水射流切割机床以水流为切割介质,是一种“冷”切割工艺。它具有如下功能与优点:

- 切割时无热变形,避免了材料的物理、化学变化;

- 广泛适应于各种材料的切割加工,有“万能切割机”之誉;

- 切口光滑平整无毛刺,一般无须再加工;

- 由数控系统操纵,切割精度高;

- 切割缝小于1.2mm,便于套料切割,节约材料;

- 加工过程不会产生污染环境的废物。数控水刀对那些用其它方法难以切割的材料如芳纶(Kevler)、钛合金及各种复合材料是非常理想或唯一的加工手段。

加入石榴砂磨料后,水流的质量增大,高速水流具有的动能就更大,在流速相同的情况下对外做功的本领就更大,从而大大提高切割能力。

What are the typical applications you see your 3-axis CNC waterjets being used for?

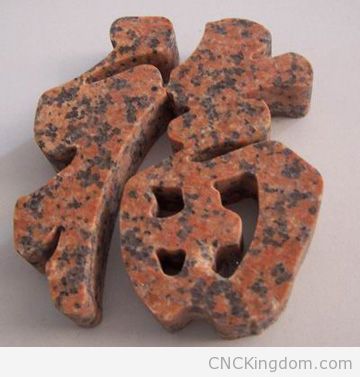

Our SAME (Sino Achieve Mechanical Equipment) water jet can cut different thickness of different material such as the exquisite marble, glass, ceramics, granite and so on, making fine & complex mosaic for building or industry.

我们的SINO超高压水切割机可以切割不同厚度的不同材料,如精致的大理石,玻璃,陶瓷,花岗岩等,制作精细复杂的马赛克拼花用于建筑装饰或工业。

Can you give me an example of why a company would require a 5-axis CNC machine over a 3-axis one?

Five-axis, this refers to a CNC Waterjet cutting machine has at least five axes (three linear coordinates and two rotating coordinate), and can be under the control of a computer numerical control system for processing simultaneously coordinated operation. Five-axis water jet cutting, compared with three-axis water jet cutting, the biggest advantage is that you can achieve any angle cutting head swing and adjusted such that the resulting pre-set at any angle cutting bevel.

五轴联动,这里指的是在一台数控超高压水切割机上至少有五个坐标轴(三个直线坐标和两个旋转坐标),而且可以在计算机数控系统的控制下同时协调运行进行加工。五轴联动水切割同三轴水切割相比,最大优势在于可以实现切割头任意角度的摆动与调整,使得产生预先设定的任意角度的切割斜面。

What is your typical lead time, from purchase order to manufactured unit?

Time of delivery: the effective date of the contract (30 days after the date of receipt of the contract deposit)

交货期是接受订单收到订金后30天内交货。

What makes Guangzhou Sino Achieve mechanical Equipment standout from the competition in the Chinese CNC waterjet and milling marketplace?

Established in 1997, Guangzhou SAME WATER JET is one of the earliest enterprises that engaged in research and manufacture of ultrahigh pressure water jet technology. Through over ten years striving, SAME has become member of Jet Equipment Standardization Committee of State Bureau of Machine-Building Industry, Chinese Structural Glass and Industrial Glass Association, Guangdong province Dimension Stone Industrial Association and Guangdong province Glass Industrial Association.

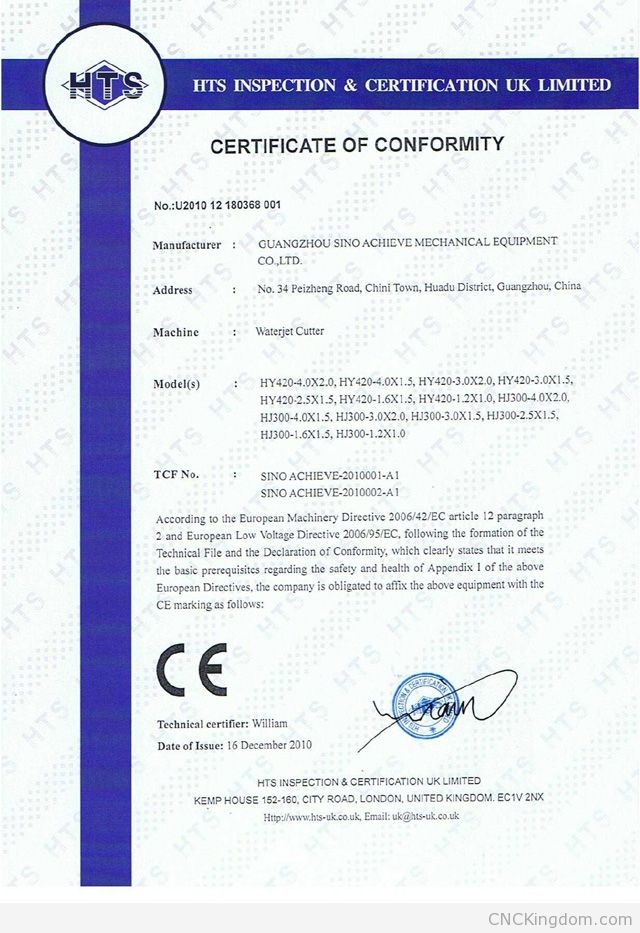

It has obtained National New Type patent Certificate (Patent NO.:ZL 97245724.0), Guangdong Province Science and Technology Advance Award and CE Certificate from CQC (China Quality Certification Center). At the same time SAME was broadcasted several times as high technical project by Mars Technology Program of CCTV. SAME waterjet machines are of good quality. The advantages such as energy saving, stable and efficient domestic and foreign customers, etc. makes SAME water jet become the preferred brand of national industry.

广州华臻机械设备有限公司成立于1997年,是中国最早从事超高压水射流技术研究制造的企业之一,经过十几年的努力,华臻公司先后成为国家机械工业局喷射设备标准化委员会单位、中国建筑玻璃与工业玻璃协会会员单位、广东省玻璃行业协会会员单位。并获得国家新型专利证书(专利*:ZL97245724.0)、广东省科技进步奖及中国质量认证中心CE认证。曾在中央电视台“火星科技”栏目作为广东省科技项目多次播出。华臻水刀一直追求高质量,以节能、稳定、高效等优点成为国内外客户首选的民族工业品牌。

Guangzhou Sino Achieve mechanical Equipment has been in business for for 16 years… how much have CNC waterjet and milling equipment changed over the course of these years?

1995 Huadu, Guangzhou , Guangdong Ji Returned Overseas Chinese joint venture by the three to create “Landes Cutting Machinery Co., Ltd. in Guangzhou” as China ‘s first professional production of waterjet equipment.

1996 China produced by the Landes first waterjet was born.

1997 corporate restructuring, the Guangzhou Municipal Construction Group takeover Landes Company, simultaneous injection of foreign capital (Hong Kong, China Zhen Enterprise Group), the newly established Guangzhou, China Zhen Machinery Equipment Co., Ltd. Address moved to Guangzhou Tianhe . China Zhen brand (SAME) HJ250 Series direct drive high pressure water jet cutting machine officially on the market, with the domestic first water cutting technology applications and the glass industry and widely recognized, open domestic waterjet direct drive pump of its kind.

1998 CCTV in China Zhen waterjet deeds as a theme, filming a documentary “magic water column ” science program broadcast on CCTV, and access to the Ministry of Science TV prize competitions.

1998 China and the domestic Zhen waterjet cutting technology was first used in the water industry, ceramic mosaic , the ceramic capital – Foshan, waterjet same stage with their peers, and achieved good results.

1998 China will attain waterjet Yunfu as demonstration bases, water jet cutting technology successfully used to promote domestic stone mosaic industries, and achieved good reputation. In the same year, company executives signed a petition published ” high pressure water jet cutting technology applications in the stone ” (Guangzhou Architecture” 1998 IV)

1999 HJ250 Series Waterjet technology through the National Machinery Industry Ministry identified key technical points waterjet equipment “high pressure piston pump check valve”, won the national patent.

2000 access to the Guangzhou Municipal Construction Group Science and Technology Progress Award, the Guangzhou Municipal People’s Government and Technology Progress Award.

2001 the People’s Government of Guangdong Province Science and Technology Progress Award .

2006 participated in the preparation Guoneishoubu water jet technology monograph “high-pressure water jet technology projects”

2007 in a glass of water cutting industry put forward the “low punch , high cut” concept and successfully applied. In the same year, through the EU CE certification

2008 China Zhen capital reorganization, from Guangzhou City Construction Group , the independent operators to enter rapid development period.

2009 a chance encounter, the company will once again moved to the site of China’s first waterjet birthplace – Guangzhou Huadu, with over 4,000 plants waterjet plane standardized production base put into use.

2009 the State Council approved the establishment of the National Standardization Committee injection technology, China has now entered the water jet industry standardization era, the company chairman Li Yuefeng became the first expert committee.

2010 former executive vice mayor of Guangzhou City, CPPCC Chairman, Comrade Deng Xiaoping ‘s southern tour escorts to visit China, Comrade Chen Kai Zhi Zhen waterjet tour guide.

2010 proposed a dynamic multi-axis water jet cutting concept and began to develop.

2011 China ‘s first national standards Waterjet – “high pressure water cutting machine” promulgated China Zhen waterjet preparation for the main one of the units.

2011 invited by the Guangzhou Municipal Development and Reform Commission, went to Shanghai to attend the Guangzhou municipal government organized the “new Guangzhou, new opportunities” Shanghai launches, and with the national first-class research institutes – Hefei General Machinery Research Institute signed a little research productivity cooperation agreement.

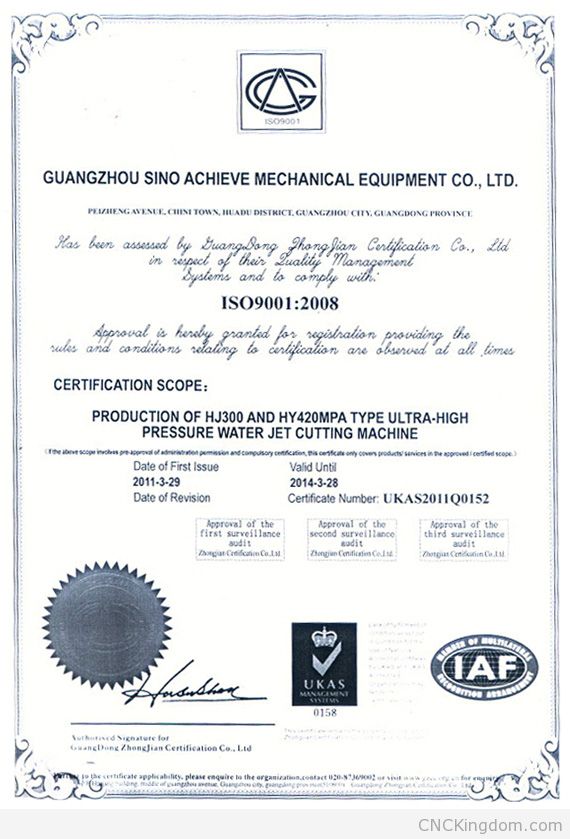

2011 passed the ISO9001 international quality system certification.

2011 “China Zhen” (SAME) brand water cutting machine to obtain the “Guangzhou City famous trademark”

2012 was “Huadu District, Guangzhou City, private technology enterprises”, ” Huadu District IPR pilot enterprise” and Huadu District People’s Government awarded the Science and Technology Award

2013 “China Zhen” brand 5-axes Dynamic Waterjet in stone, ceramic mosaic industry has wide application and good reputation.

2013 adding “American Water Jet Technology Association (WJTA)”, as its corporate members.

1995年,广州花都,由三名粤籍归国华侨合资创建“广州朗德切割机械 有限公司”,为中国第一家专业生产水刀设备的企业。

1996年,由朗德公司生产的中国第一台水刀诞生。

1997年,企业重组,广州市建筑集团接管朗德公司,同时注入境外资本(香港华臻企业集团),新成立广州华臻机械设备有限公司,地址迁至广州天河。华臻品牌(SAME)HJ250系列直驱式超高压水切割机正式投放市场,与国内最先将水切割技术应用与玻璃行业,并取得广泛认可,开国产水刀直驱泵之先河。

1998年, 中央电视台以华臻水刀事迹为题材,拍摄纪录片《神奇的水柱》在央视科教栏目播出,并获得科技部电视节目评比一等奖。

1998年,华臻水刀与国内最先将水切割技术应用于陶瓷拼花行业 ,在陶瓷之都-佛山,与同行水刀同台竞技,并取得良好成绩。

1998年,华臻水刀将广东云浮作为示范基地,成功将水切割技术推广运用于国内石材拼花行业,并取得良好口碑。同年,公司高层联合署名发表论文《超高压水射流技术在石材切割的应用》(《广州建筑》

1998年第四期)

1999年,HJ250系列水刀通过国家机械工业部技术鉴定,水刀设备关键技术点“超高压柱塞泵单向阀” ,获得国家专利。

2000年, 获得广州市建筑集团科技进步二等奖、广州市人民政府科技进步二等奖。

2001年,获得广东省人民政府科技进步三等奖。

2006年,参与编写国内首部水射流技术专著《高压水射流技术工程》

2007年,在玻璃水切割行业提出”低压打孔、高压切割“概念并成功应用。同年,通过欧盟CE认证

2008年,华臻公司资本重组,脱离广州市建筑集团,独立运营,进入高速发展期。

2009年,因缘际会,公司再次将厂址搬迁至中国第一台水刀的诞生地–广州花都,拥有四千平面标准化厂房的水刀生产基地投入使用。

2009年,国务院批准成立全国喷射技术标准化委员会,中国水射流行业从此进入标准化时代,公司董事长李岳峰成为首批专家委员。

2010年,广州市原常务副市长、政协主席、小平同志南巡陪同者陈开枝同志莅临华臻水刀参观指导。

2010年,提出多轴联动的动态水切割概念,并着手研发。

2011年,中国首部水刀国家标准-《超高压水切割机》颁布,华臻水刀为主要编写单位之一。

2011年,受广州市发改委之邀,赴上海出席由广州市委市政府举办的“新广州、新商机”上海推介会,并与国家一类科研院所-合肥通用机械研究院签署产学研产略合作协议。

2011年,通过ISO9001国际质量体系认证。

2011年,“华臻“(SAME)品牌水切割机获得“广州市著名商标”

2012年,获得”广州市花都区民营科技企业“、”花都区知识产权试点企业“称号及花都区人民政府颁发的科学技术奖

2013年,”华臻“品牌五轴五联动的动态水刀在石材、陶瓷拼花行业取得广泛应用及良好口碑。

2013年,加入”美国水射流技术协会(WJTA)“,成为其企业会员。

You have a very large factory and good CNC product range – do you serve mostly the domestic CNC marketplace or do you also have a number of distributors abroad?

We already have a large-scale high pressure water cutting machine factory, and serve mostly the domestic CNC marketplace but we don’t have oversea distributors,only some customers. Now we are planning to open overseas markets.

我们已经拥有一个规模较大的超高压水切割机制造厂,已经占有较大的国内数控市场,但在海外市场只有一些顾客,现在正在开拓海外市场。

You can contact Sara directly at Guangzhou Sino Achieve Mechanical Equipment by visiting their website at http://www.gzsamew.com

Here are a few more pictures that Sara was kind enough to share of their CNC waterjets in action!