Interview with Michael Joyce – Founder of B9Creator

I recently got into contact with Michael Joyce, the founder and designer of B9Creator to learn more about his views about the 3D printing industry and the challenges of developing your own 3D printer. His creation has enjoyed tremendous success using Kickstarter to fund the production of his machine – back in June 0f 2012 he got more than 10x the backing he was looking for and this year, he’s about to do it again but hurry – you only have until April 9th!

–

How did you get into 3D printing in the first place? When was the first time you saw a 3D printer in action?

I was initially drawn into 3D printing back in 2011 when I began to wonder about it’s potential uses for aerospace. My research led me to DLP based systems because of the potential for much finer resolution than the hobbyist FDM systems I read about. The first time I saw a 3D printer “in person” was early 2012, it was my own DLP based proto-type.

No leap, I went straight to building my own. Finding a suitable resin material was the first big challenge. Developing a method to new (and unpatented) method to release the cured layers from the projection window was also a challenge.

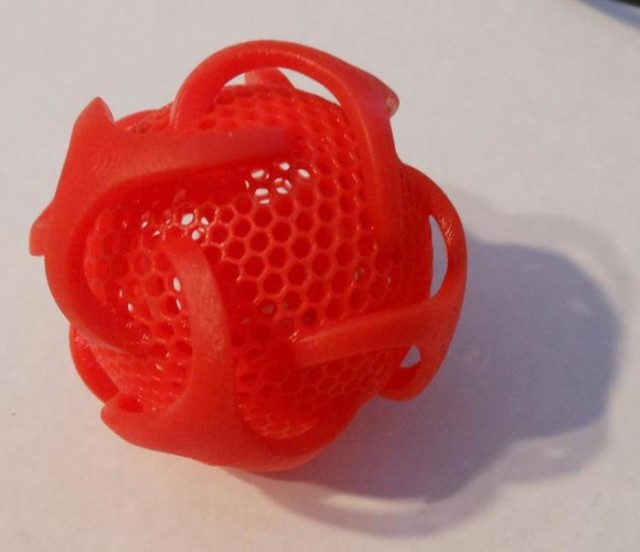

B9Creator – designed by Michael Joyce

Higher resolution potential and the ability to use the output in “lost wax” casting applications.

Not as much as I’d like, I’m spending all my time developing and delivering machines.

My timing was good, Kickstarter popularity was just peaking last year when I did my first campaign. I think I did a good job showing my ability to produce what I promised and that helped a lot as well.

We actually came out (and delivered) before the Formlabs project. Our machine focuses on smaller, higher resolution output. They have a slightly bigger build area but our potential resolution is higher. I think that’s important for applications such as Jewelry, miniatures and model makers.

Consumer FDM must find their market beyond hobbyists, I’m not sure they’ve done that yet. Our printer is being purchased by individuals and companies that plan to use it profitably in their business.

Learn what software is available for your industry. Try using that software first, to get comfortable with it’s capabilities and limitations. Then perhaps a low-cost machine to “learn” with is in order.

–

I want to thank Michael for his time, he’s very busy and was kind enough to answer my questions. You can find out more about B9Creator at http://b9creator.com where you can order your very own production ready machine right NOW!