Interview with Ken Susnjara of Thermwood Corp (USA)

Thermwood Corporation has an impressive range of industrial CNC routers but more importantly, Ken started the company back when NC was transitioning into CNC nearly half a century ago! This makes Thermwood the oldest CNC router company in the world and they are also the only CNC manufacturer in the United States with a GSA certification. I approached Ken to see if I could interview him and he was very keen… watch their corporate video for a quick review of the company.

Back in 1969 CNC machines were very much in their infancy in the United States – what drove you to start a company instead of working for somebody else in the industry? Did you achieve amazing entrepreneurial success right out of the gate or did it take a while for people to warm to CNC routers back then?

There were no CNC routers in 1969. In fact, there were no microprocessors. Thermwood started when I was in college, a small engineering school in central Indiana now called Rose Hulman Institute of Technology. I was in school and needed money. I got a job in the school cafeteria, worked a week, was paid $14 and quit. There had to be an easier way!

I decided to start a company because people who owned companies seemed to have a lot of money. At the time I didn’t have a car but was taking flying lessons whenever I could scrape together enough money. It was a four mile walk each way to the airport. From that experience I decided to make airplane parts because they were expensive so I wouldn’t have to make a lot

of them because I didn’t have a lot of extra time.

Working with a friend, we built a thermoforming machine using army surplus parts in the school shop and we started thermoforming wheel pants for fixed gear aircraft. The only other wheel pants were made from fiberglass and cost $54 a pair. We sold ours as a kit for $22. They cost us $3 to make. $19 profit on a $22 sale….sounds about right! This seriously warped my judgment.

I left school, got a really good job at Alcoa and my standard of living took a nosedive. I began working in the evenings and discovered a way of making thermoformed wood grain parts which were perfect for the furniture industry at the time. They were making plastic parts using an injection molding machine running $10,000 molds on a minute and a half cycle. My process used half the amount of plastic, on a $500 mold and a 5 second cycle, and the parts looked the same. I quit my job and was in the plastic business. That’s where the name “Thermwood” came from, thermoformed wood grain parts.

Things went great for a few years until the Arabs decided to place an embargo on oil. The price of our plastic quadrupled and the furniture industry quit using plastic parts. We had to turn to other products and these new products needed to be trimmed. After hand trimming for awhile, we decided we needed to automate. There were some machines called NC routers that used punched tape to move around but they were a quarter of a million dollars each. Good idea but way too expensive.

At the time I bought a new product called a “calculator”. This was an amazing device it could add, subtract, multiply and divide and only cost $960. It had nine memory positions which gave me an idea. If we could make each position represent a point on the machine table, we could cut things that had up to nine moves. So how did this thing work?

I was told it used a new device called a microprocessor. I didn’t know anything about that but did find a book. It was loose-leaf paper in a three ring binder. I read the book and understood virtually nothing but I did have the name of the author. I called him and asked if we could do what I wanted. He said no problem. It would cost about $6,000 – $8,000 and take

about six weeks. It actually took eighteen months and cost a million and a half dollars but we had the first commercially available CNC control. There were minicomputer based CNC controls used by the military at the time but this was the first CNC control you could actually buy on the open market.

To understand how crude we were, all programming was done in hex using a small keypad as there were no assemblers at the time. There were a lot of all-night sessions, however.

As things advanced we began using CPM, and operating system developed by Osborne Computer. It didn’t work very well so we wrote our own operating system, which was a complete, multi-tasking system able to run four independent threads, all before there was MS-DOS. When MS-DOS came out we switched to it and somehow used it as a multi-tasking system. Eventually we switched to OS-2, which was pretty nice and finally when that got killed off by Microsoft we switched to Windows and turned it into a real-time

system.

In this type of fast moving business there is no instant success and even less stability. Things can go great today and be absolutely awful tomorrow. You just have to keep moving. In the early eighties we got into the industrial robot business which was touted as the next huge growth area. We found you could make a small fortune in industrial robots, you just had to start with a large fortune. After losing more money that you can count we turned back to CNC routers.

It’s a fast moving market with a lot of competition. We have tried to compete by offering new, fresh and innovative technology to separate us from the others. We are all pretty technical here and this does let us play with all the new toys.

This thing keeps moving and today we are working on an all new approach that could very well replace CNC routers or at least the way CNC routers work today. We hope to have it out the early part of next year.

Thermwood has an incredible array of CNC routers – it’s quite impressive how there is something to suit just about every industrial market segment. Did this range evolve over time or was a large diversity of CNC routers part of the plan from the beginning?

First, there was no plan in the beginning. You do what seems right at the time. You must really get to know your customers on a personal basis and try to understand what they really need. Then you use all your creativity, experience and skill to try to offer a solution to their needs. Make money by helping them make money. We don’t sell machines, we sell what the machines do. We sell solutions that make more profit for our customers. That’s our focus. As we get into more and more markets, the solutions for each may be a little different so you end up with a large range of products. Over time, all of those products will continue to change as our customers change.

Other than your divestiture of Digital Sky, Thermwood didn’t follow the traditional route of acquiring to generate marketshare, instead, it seems you’ve just been slow and steady wins the race. Do you think this approach is what has allowed Thermwood to survive and prosper for almost half a century? Did you ever consider launching Thermwood into the public markets?

We have an innovative, can-do, swashbuckling culture at Thermwood. We can turn on a dime and abandon practices that are ingrained almost instantly. I’ll give you an example. Years ago a salesman came here to demonstrate a three-dimensional laser. We already had a huge investment in straight line lasers and had developed technology, at great expense, that allowed us to align and compensate our machines to a high level of accuracy. We had everyone involved in this process in the demonstration from the hourly workers to top management. We were impressed, held a twenty minute discussion and ordered two systems at $150,000 plus each before the salesman left. We had to completely abandon existing technology and develop all new systems. We made that decision in twenty minutes. It worked great, vastly improved our products and saved a ton of money.

The problem with this is that there are not a lot of companies comfortable operating this way. Most find it totally unpredictable and unstable and some even call it reckless. We have looked at other companies but the cultural clash would not have worked. In the markets we focus on we tend to be the technical leaders so it is unlikely we will gain valuable technology

or market share by buying into it. We could potentially gain some market share by moving into aligned products but, most likely, these will be markets and areas we don’t really know. Just because you do well in one market doesn’t mean you will be successful in others. I’ve seen a lot of successful companies fail because they thought that their success in one area meant they would be successful in anything else they tried.

As for being public, we tried that. We went public in the early eighties in the midst of the robot hysteria. We were listed on the American and Pacific stock exchanges. That didn’t work all that well. I often feel that as we came to New York the investment bankers looked out their penthouse windows and said, ‘Lookie here, here comes some country folks”. It was very expensive, took an inordinate amount of management time and we got very little for it. Once they started passing new rules for public companies in the late nineties, we bought back enough stock that we were able to de-list and become private again. As you might imagine, it doesn’t hold much appeal for me.

From virtual service and control nesting to dynamic CAD drawings and 3D laser compensated cutting tables – you have quite a bit of technology that goes into each Thermwood that most people would never even think was needed much less realize the benefit of without prior to machine acquisition. How much of your sales cycle is focused on educating customers on these features that differentiate it from the competition?

We do try. As we compete, all others try to focus the discussion away from the control toward the machine mechanics or low price, or anything else trying to convince the customer that all controls are the same and they shouldn’t bother with that. There are two things that really help us in our efforts. First, if we can get the customer to come and visit us, we can demonstrate all the features that help you make more money with our machines. Also, we have customers in every part of the country and I would not hesitate to have a prospect talk to any of them. They know how well these things work. Most new prospects know of one or more of them which helps a lot. Repeat sales are also a large part of our business.

Recently we started a program of separating ordinary routers from “Smart” routers in the marketplace, a smart router being one that has the advanced features you mention. When you tell a customer he has a choice between an ordinary router and a smart router, he naturally wants to know the difference and you enter a serious conversation about advanced features and how they save material, labor and reduce errors and scrap. That effort is starting to have an impact but it is still fairly new.

Thermwood is very active in social media including YouTube and I was wondering how important you’ve found this method of outreach towards acquiring more customers vs more traditional means like tradeshows and mass mailings.

As we entered the financial downturn a few years ago, the guy that was heading up our very traditional marketing effort decided to retire. We put my tech savvy son in charge of marketing and gave him some other young guns to help. We told him we would meet a couple times a week to teach them all the techniques and practices. Don’t make waves until we work our way through this.

Within two weeks he had cancelled 85% of our print ads, cut trade show expense in half and switched focus to the internet and social media. They began giving management training sessions on push and pull marketing and electronic media to teach us how things are done today. They went from focusing on three markets to focusing on over a dozen. The three markets shrank to the point we would have gone out of business. The new markets supplied enough business to keep us going. At this point I think this

“social media” thing is rather good, although I’m still not sure I totally understand it.

I absolutely love CNC routing… coming up with projects and seeing a CNC machine cut my virtual ideas into physical prototypes is mesmerizing even after two years – does this feeling ever go away?

No. It’s always fascinating. I have been running machines for almost forty years and I am still fascinated when they cut something new. In our business we work with hundreds of companies from around the world making almost anything you can imagine. It’s actually fun because you never know what’s going to come through the door next.

Thermwood has an extensive dealer list and aggressively expanding to more countries around the world. What has been the leading fuel for this growth abroad?

We want to sell more and a few years back we said “why don’t we try to sell overseas” and its been working our pretty well. We have found the key to entering a new country is finding some folks that you can work with who are excited and enthusiastic, so we expand into areas where we find the right folks to partner up with.

What are your thoughts on 3D printing? Do you see one day additive and molecular production methods ever replacing subtractive ones?

3D printing is really fascinating but probably for a different reason that what you think. The process itself is not particularly efficient and, although there are some exceptions, virtually anything you make can be made faster and cheaper using mass production techniques. The real appeal for 3D printing is that you can make anything you have an electronic file for and you can make it locally. There is no packing, no shipping, no handling, no hassle. We call it “distributed manufacturing”. The product is not made in a factory and sent to the customer but is made at or near the customer from an electronic file. There are huge benefits and appeal to this. We have been developing technology to make furniture using distributed manufacturing cells that can operate inside a retail store. Imaging going to a furniture store, selecting the furniture and size you want and having it made right there so you can take it home. This is not all that far off.

Anything else you wish to add Ken?

Each time I think everything is about done a whole new wave of ideas and technology breaks. We are going through just such a period right now. After almost fifty years in business it’s still fun.

You can find out more about Thermwood Corporation by visiting their website at http://www.thermwood.com and reading-up on their blog at http://blog.thermwood.com.

————-

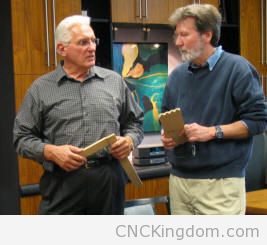

For those out there that enjoy ShopBots like myself, ShopBot Tools has worked with Thermwood Corporation for years to help build-up the CNC table router cabinet industry. The two giants of the CNC table router world – Ken is on the left, Ted Hall, founder of ShopBot Tools, on the right.

For those out there that enjoy ShopBots like myself, ShopBot Tools has worked with Thermwood Corporation for years to help build-up the CNC table router cabinet industry. The two giants of the CNC table router world – Ken is on the left, Ted Hall, founder of ShopBot Tools, on the right.

You can read about their strategic alliance here: http://www.shopbotblog.com/index.php/2009/04/cabinet-software-amazing-new-opportunity-for-shopbotters/