Henry Liu, Engineer/CEO at Full Spectrum Laser (USA)

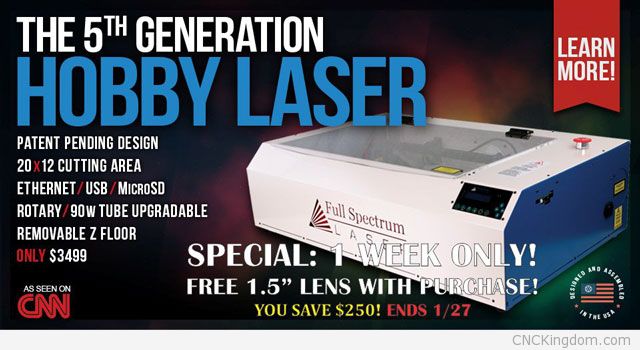

In September of 2012, Henry’s company Full Spectrum Laser launched an incredibly low cost 20″ x 12″ CNC laser on Kickstarter with a goal of getting a 100$K in orders… they blew through that big time and got a grand total of 259,327$US with over a hundred backers! You can see it here: http://www.kickstarter.com/projects/fsl/affordable-20×12-laser-cutter-engraver-assembled-i?ref=users

As impressive as that was, they’ve recently launched another campaign on Kickstarter (http://www.kickstarter.com/projects/fsl/pegasus-touch-laser-sla-3d-printer-low-cost-high-q/) for their Pegasus Touch Laser SLA 3D Printer and although they still have 11 days to go, seeking the same 100K$US in orders, they have received over 518,102$US from over 250 backers!

I tried crowd funding my last book and it was a major flop, the campaign, not the book which is about to be my best selling thus far! I can completely appreciate the amount of work involved in succeeding in this world.

So I sent off a message to Henry to see if he’d be interested in being interviewed here on CNCKingdom.com and he thankfully agreed – imagine getting 5x the number of orders you were expecting within a 30 day period and you can really appreciate how busy he is these days!

You can get a hold of Full Spectrum Laser at http://fslaser.com.

What is it about your background that made you want to start your own laser engraver manufacturing business and was eventually getting into other CNC technologies like 3D printing and routers part of the plan?

I have a BSc from University of Toronto Engineering Science and a MS/PhD from Stanford University. I’ve always enjoined building stuff and the company started out of my Las Vegas garage.

Combining advanced software, electronics and moving parts was my field of expertise. We grew quickly and now have several offices with around 25 employees.

Full Spectrum Laser has offices in the United States, China and Mexico, what does each office handle and what are the challenges of running a multinational corporation in such different locations (taxes, laws, languages etc.)

Our US office does assembly and most engineering as well as tech support and sales.

Our Mexico office handles basic laser tube research in conjunction with a University lab. Our Chinese office is based out of Wuhan where my two Stanford PhD classmates are professors at major university. They do basic science research for us also.

Full Spectrum Laser has a wide variety of CNC lasers (up to 150 watts) along with a small desktop CNC router and now a desktop 3D printer. There aren’t many companies that expand so quickly across a variety of technologies. Are any of there components sharable or does each technology have to have specific hardware and software? I’m wondering if there is some synergy between them manufacturing wise to help keep costs low.

Yes we use the same laser control software in all our RetinaEngrave machines. RetinaEngrave is in our opinion one of the most advanced control software/electronic combinations allowing for precise laser control.

It seems you’ve taken the same approach to the 3D printing world releasing your Pegasus Touch Laser SLA 3D printer… how is does it compared to the B9Creator or FormLAB’s offerings?

We do not compare directly with other company printers. We think the two you mentioned are great and we have nothing bad to say about other companies. We offer some unique advantages such as larger area, faster speeds and advanced touchscreen electronics with our 3d app store.

You decided to seek funding for your 3D printer on Kickstarter and already reached more than 5x your initial goal of 100K$US. How did you manage to have so much incredible success with your campaign? Why go on Kickstarter to begin with?

Kickstarter is a great platform and we’re happy to be a part of it. It brings us new customers and serves both as a great launch platform as well as a marketing platform.

How did you achieve such amazing speed with your 3D printer? 3K mm/sec is incredibly fast yet still achieve the incredible resolution SLA offer? Generally in the CNC world, the faster your machine, the less resolution you can achieve.

We use galvos which are closed loop spinning mirrors with very little mass. Our high end fiber laser marking galvos can move at around 7000mm/sec. Our 3D printer galvos can maintain speed at 3k mm/sec based on our experience with our high end marking galvo line of products. Since the galvos are closed loop they correct errors on their own.

What’s the difference between a laser used for 3D printing vs engraving/cutting?

CO2 lasers use 10.6um and our fiber laser is 1um. Generally those two lasers are in tens to hundreds of watts. Our 3D printer uses 405nm at around 100mW. The 3D printer uses a chemical reaction rather than a heat or vaporization effect so can use much lower power.

What are some tips of advice regarding achieving the success you have on Kickstarter? How do you manage to be so successful in your hardware sales using that medium?

I think the most successful projects are making things people want at a good price. If they can buy the same thing for the same price somewhere else there will be no interest. You should also prepare the project so that it’s almost ready to ship and inspire confidence that you can deliver quickly. Ideas only are unlikely to do well.