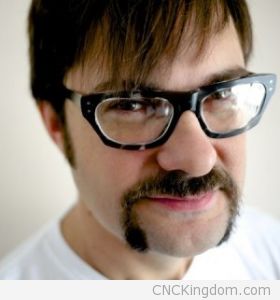

Greg Flanagan, Owner of Tree on a Hill Workshop (USA)

With over 30 years of experience across a variety of industries, from broadcasting to internet… Greg always had a shop to explore his ideas and I’m very happy he agreed to be interviewed by me. He’s an amazing resource about a variety of topics!

The major takeaway from this interview is one that I wholly agree with and as a self-taught learner. “formal education often leans too heavily on adherence to known standards to the detriment of exploration and investigation.”

You can visit his Tree on a Hill Workshop online at http://www.treeonahillworkshop.com.

You’ve had a number of careers from sales to admin, design to fabrication – which did you enjoy the most in hindsight and how did all those past hats help you with your current job at ShopBot Tools as an independent contractor?

I have learned a lot in every position I’ve held. I tend to go where my interest leads me. I view every job as an opportunity to learn something new. My current career as an independent CNC consultant and fabricator is a direct result of my year at The Mill and my previous careers in the software and internet business.

I have learned a lot in every position I’ve held. I tend to go where my interest leads me. I view every job as an opportunity to learn something new. My current career as an independent CNC consultant and fabricator is a direct result of my year at The Mill and my previous careers in the software and internet business.

I’ve lived in several countries around the world for years but to be honest, nothing really comes close to the design community you find in the United States. There is just something in the American psyche that’s tough to beat creatively, organizationally and the massive enthusiasm and optimism is spectacular. Why do you believe this is the case?

I guess I’m not sure but I think we are optimistic at heart. These positive vibes lend to a supportive culture. It’s like improv.

Considering that most of the CNC technologies we enjoy now all come from America – thanks to military R&D origins during the war – what do you think is coming-up that few people have heard about in the future in the CNC area? I’d see atomic building methods in maybe 15-20 years where you need to know chemistry to create new materials and understand how one element interacts with another. I’d also see house-scale 3D cement printers as well on the macro scale.

I see CNC knowledge allowing we “robot controllers” to branch out far beyond shop tools and into automation of all kinds.

Are you largely self-taught in all the abilities you currently have other than saleforce work? What are your views on formal education when it comes to the design and creative fields?

I think it is important to learn frameworks for design, as with any skill. They allow us to communicate our ideas more efficiently with others who have been trained in the same way. On the other hand, I believe that formal education often leans too heavily on adherence to known standards to the detriment of exploration and investigation. I believe experimentation is more important than standardization in many cases.

What are your views of ShopBot in general and their newest creation, the handibot? Do you see more small API driven smart tools coming out into the marketplace? I’d see so many applications for this vs using “dumb” power tools.

I think shopbot is an amazing company. I applaud their focus on innovation and I think they are on to something with the handibot. A moble, automated building tool?!?! It seems to me to be platform that can open doors for all kinds of automated devices. The fact that they are making this a community driven effort is great. Innovation often speeds up when you invite the crowd.

Anything else you’d like to add?

This is an exciting time to be a maker. It feels a little like the early 90s with the internet. Right now, you have all of the early adopters jumping in and laying the groundwork of CNC and automation. Components are getting cheaper, knowledge is getting shared and archived, and early adopters are making the mistakes that future breakthroughs will be built upon.