Edmund Liew, Senior Product 3D Designer @ Why? BD (Singapore)

Product 3D Designer Edmund Lieu has worked with and for a number of well known brands helping them come-up with awesome designs though the years.

Key takeaways from this interview:

- Study your craft in as many different locations and within different cultures as possible to be a well rounded designer.

- 3D printing is used increasingly in the field to prototype and play with design elements – it’s a technology that’s here to stay along with other 3D visualization tools.

- Let your passion and ambition drive your career.

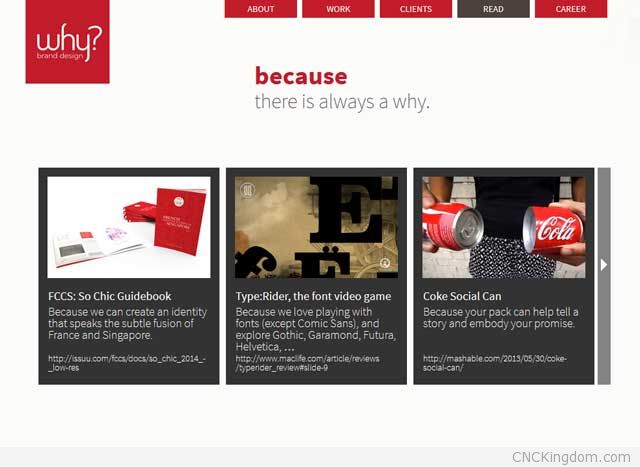

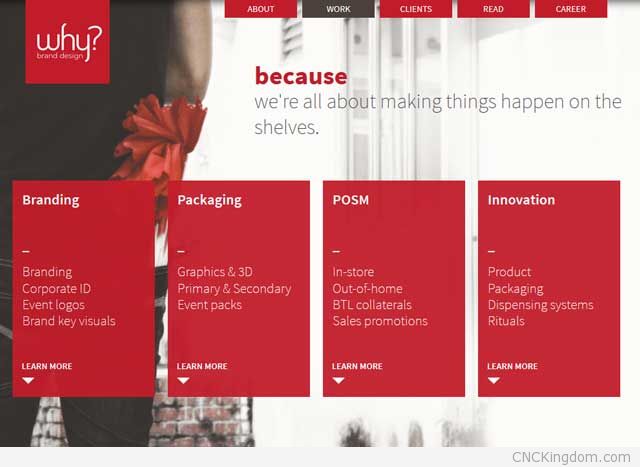

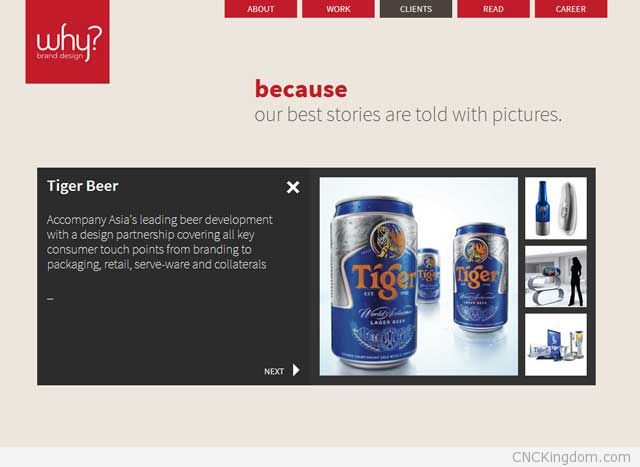

You can contact Edmund by visiting http://www.whybd.com.

You got your diploma in Mechanical Engineering in Singapore Polytechnic then followed-up with a BA in Industrial Design at the University of New South Wales. What were some of the differences you noticed taking design courses in two very different countries?

I think looking back at my education journey, I’m quite privileged to be educated in 2 different courses in 2 different country. I didn’t think I’m the sort of engineer to be when I took up Mechanical engineering back in Singapore Polytechnic. I felt that i needed to be develop with a set of skills.

I think looking back at my education journey, I’m quite privileged to be educated in 2 different courses in 2 different country. I didn’t think I’m the sort of engineer to be when I took up Mechanical engineering back in Singapore Polytechnic. I felt that i needed to be develop with a set of skills.

A set of logic & systematic approach looking at things, naturally it is to solve everyday problems. Naturally engineering came to play. In Singapore, it’s probably known to be kinda of a stable perception by social standing, jobs are plenty if it is related to engineering especially in Mechanical engineering. In Singapore, everything is structured, systematic, things have a reason to function, or rather things exist for a purpose eg. The buses/trains that we take to work/school, the building that houses commercial workspaces or residential purposes, etc. It is the pragmatic approach that Singapore has since its independence from its colonial rulers in history.

Mechanical Engineering or Engineering in general to my understanding is similar to Product/Industrial Design, finding a solution to a problem, making life easier but in a rather 1 dimensional approach with a fail-safe system approach. You have to understand how things work, how things come together, in short how systems work.

Upon finishing my Mechanical engineering diploma, I decided that Product/Industrial Design would be the choice of my interest, given the fact that that’s where my path should be. So I did a BA in Industrial Design in University of New South Wales. I deliberately chose a location of a balance of 2 things, the environment and the people. Yes there are wonderful better design courses around the world. But I decided to stick to the decision, boy I am thankful of the decision that I took.

1) Environment – political landscape does help in design, not being afraid to voice your concerns.

2) People – Sydney Australia, has probably one of the highest concentration of international people congregating together. People of all walks of life does benefit design as people of all sorts think differently in their culture and language.

What were some of the products you worked on while at Shimano Singapore and Markelin Sharewards? Did you do any internships before getting these jobs or did you just find them through family and friends or did the experience you gained at Ant Industrial Design as an apprentice provide you with all the required skills?

Paid Internships/freelance are the best way to kickstart the Industrial Design career. You get to learn the Industry needs and the challenges that are along the way. It is not necessary about the money but the experience working as a designer, which makes a lot of difference, if one were to work for money, than passion.

You are currently working as a Senior Product 3D Designer at Why? Brands Design… what are some of the tasks and projects you are currently working on that you can share? What is the overall design approach you take when developing something for the marketplace?

Well, most of the projects I have worked on are mostly packaging design visuals. Before that I worked on interior design furniture products and bicycle sports components products.

How well did you education prepare you for the work you currently do? Things have changed a lot since you graduated especially in the 3D visualization and printing fields.

Technical training – understanding the physics & the environment & materials, problem-solving.

Design training – making the interaction between human & product & environment a better place to live in, having multiple creative solutions.

Yes I do agree with you, things certainly have changed tremendously since I graduated. There’s a greater need for visualization at its highest level in the industry, 2 of the most highly valuable elements.

3D rendering visualization & 3D Printing. These days people can greater access to visualize the actual 3D product how it look like in its actual material, colours and lighting almost immediately, Thanks to the advancement of 3D rendering software like Bunkspeed & Keyshot that we know today. 3D Printing today we know it, its affordable, accessible and it cuts a lot of waiting time when it comes to prototypes.

Back in those days of 3D rendering and 3d Printing, it was awfully difficult to learn and operate, expensive to get the machines & time consuming. But today, phew, gone were those days. Things are definitely getting exciting with these 2 different elements being easily accessible to designers.

What advice would you give to somebody interested in working as a senior product designer? When you are reviewing resumes to see who you’d like to add to your team, how much of a role does education play in your decision making over the portfolio they offer?

A key interest to make the world a better place to live in visually & functionally.

Creative solutions & risk taking projects.

Able to Lead junior designers to final objective and arrive a final solution.

Character.

Challenge the norm with creative solutions.

Positive, Optimistic & Team Player spirit.

How do you see the field of industrial design evolving over the next few decades especially in the area of 3D visualization and manufacturing techniques? Are we seeing a new beginning of mass-customization at the industrial level for products thanks to 3D printing?

We are seeing more and more usage of the 3d printers. In traditional model making, it takes time to make and thus better to appreciate its process, but as the industry evolves, time is often the competitor at this case the products have to out on the market as quick as possible before your competitors thrives you out of the market.

I think we are seeing more and more entrepreneurs out there also thanks to the massive available and affordable 3d printers, people are able to showcase their ideas at a better affordable visual and present a creative solution to the ever changing needs of the world.