Echo Liu, International Sales and Marketing at HLH Prototypes (China)

Echo Liu is the International Sales and Marketing at HLH Prototypes, a Chinese company that offers a huge range of prototyping and manufacturing services from product development to CNC machining.

I’m always astounded by the scale of Chinese manufacturing so I enjoy learning more about what makes them run and their capabilities. Key takeaways from this interview:

I’m always astounded by the scale of Chinese manufacturing so I enjoy learning more about what makes them run and their capabilities. Key takeaways from this interview:

- Having every conceivable CNC machine type in house means quicker turnaround and higher profit margins.

- Segregation of duties with a manager handling a specific project from start to end ensures quality.

- Having local relationships to augment your capabilities is another method to ensure both quality manufacturing and extra profit margins.

You can contact Echo at http://www.HLHprototypes.com.

HLH Prototypes offers a host of services from design and prototyping to metal work, tooling and production. Which services are the most popular with your company and what is your overall production capacity? How many employees does HLH Prototypes have and do you serve a mostly domestic or international clientel?

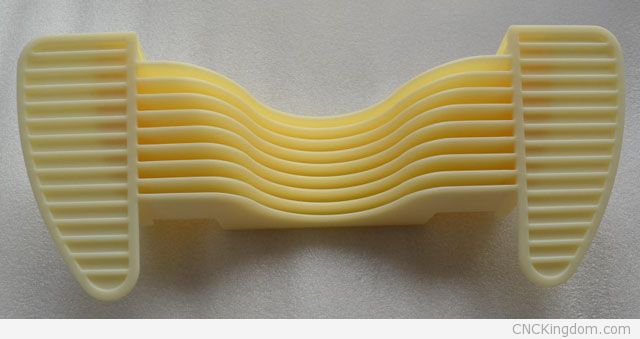

Basically we offer a massive range of services as the customer request, such as, CNC machining in plastic and metal material, 3D printing, RIM, FDM, and low volume production. But mainly we focus on our CNC machining.

The overall production capacity in our company is quite large, one of the top ones in Shenzhen. In our company there are more than 30+ engineers and 300+ workers.

We have lots of famous clients from all over the word, such as Nikon, Land Rover, ARRK…

What is the process you follow when you go about undertaking a reverse engineering project? How extensive is the research and can you give me a case study of something you’ve done recently and the results you showed to the customer?

Basically the clients sent us the files for a quote, our professional engineers would check the files first and offer some suggestions. Once the clients agree, we would arrange to production with the final data.

Currently there is a customers that makes a bicycle model in UK, he need some flexible rubber parts, but without any hardness request. And finally we sent some samples to customer for checking first. After the client approve, we re-start to machine.

HLH Prototypes has lots of machinery, from CNC and FDM to SLA and Vac Cast… how long of a lead time to you need to produce prototypes and at what stages do you take on such projects? What is your turnaround to produce a fully “production ready” model and do you also help with manufacturing (onsite or offsite)?

Yes, indeed, we have lots of machines in house. All parts would be machined in our own factories and we have 2 factories.

It is difficult to offer you a lead time without any specific parts. For example, if we machine a iPhone box with CNC machines in ABS material, the manufacturing time is about 3 days. I would be in charge of all communications and final packaging through the projects. If the clients needs to make large volume production, we could also help them.

Can you expand on your tooling and metal work services? What types of files do you need, what size projects do you normally undertake and what is your turnaround time? Can you give a few examples of your work in these areas?

HLH Prototypes could help customers to make tools and metal works. We have one model factory in Shenzhen. We could deal with most of files with IGES, STP, X-T, STEP, and some SolidWorks formats.

For CNC machining, the largest size we could machine is 3000*1200*600 mm. The turnaround time depends on the parts.

What makes HLH Prototypes unique within the Chinese prototyping industry? How do you go about competing against others in the same field and why do companies choose yourself over others? What kind of outreach marketing does HLH Prototypes partake in?

With over 16+ year experience in rapid prototyping, HLH Prototypes has lots of trained and professional engineers and many Germany imported machines in house.

The quality of all parts machined in HLH Prototypes are assured and we could offer the QC reports for your parts. We would have one person to control the whole work processing, from the programming to packaging.

High quality, one to one services, low cost are the reason we are at the top of our game. Currently we are still dedicated in rapid prototyping field.

I’m very impressed with the casing you produced for a larger German medical device manufacturer, can you give me an idea as to how much work it was to produce this model and the tolerances that you had to meet or exceed for its production?

It is really hard to explain how much work is produced. That’s our engineers’ and workers’ business. Sorry for that. Hope you could understand. For tolerance, basically, it would be controlled within 0.1MM if we choose CNC. For 3D printing, it is 0.05MM.

Anything else you’d like to add?

If you have any similar works or want to test, please sent your files from some small parts first. You must be impressed by our high quality parts finally.