Dream of ShopBot PRSAlpha Came True!

The evolution of CNCKing.com through to CNCROi.com is pretty interesting to me, you can read about it in more detail here:

But to summarize, before I knew CNC machines existed, I wanted design some woodworking projects but being in a small apartment in Korea teaching ESL, I had no facility for equipment so I began using my self-taught 3D animation skills to make projects with videos and that’s how WoodMarvels.com (now CNCKing.com) began.

This was my very first video as part of this “new” site.

Things have evolved tremendously over the years in both CNC design skills and rendering capabilities.

My goal was to design 100 CNC projects and as part of that, publish a series of books, almost annually, to show how the designs came together and some of the lessons I learned along the way.

Over the course of the next few years, I ended-up releasing 5 books, which the anthology you can buy in PDF form on CNCKing.com or on Amazon.com.

My very first introduction to CNC machines started with my amazing ShopBot Desktop which has traveled with me around the world literally, and I still have it in my shop to this very day!

I learned A LOT about not only CNC machines but also how to best design for them with this machine and I can’t thank ShopBot Tools enough for introducing me to this world, Bill Young and Angus Hines taught me how to change bits and set-up cutting files… then I went nuts with content!

Fast forward a few years, my next machine was a Trotec Speedy 400 flexx that I got when I moved back to North America and founded CNCROi.com in the process.

I knew nothing about CNC lasers before moving to Australia and I left with a top of the line CNC Trotec Speedy 400 flexx, with my ShopBot Desktop!

Over the past few years, my equipment list has grown exponentially as did my customer base, aerospace to military, small signs to large installations.

During this time, I said NO to a lot of really good contracts because I didn’t have a large sheet CNC router, sure, I could have bought a cheap import but I want a QUALITY machine and nothing short of a ShopBot would work for me.

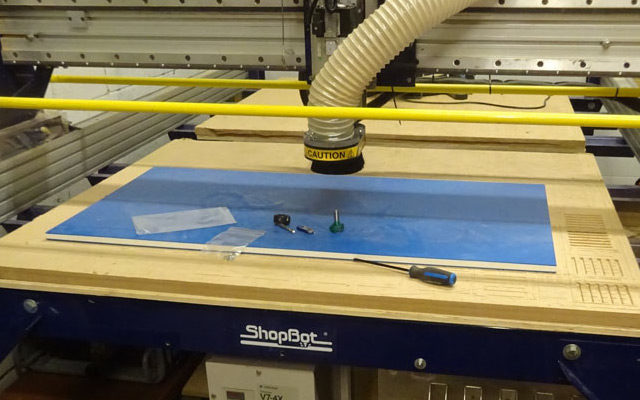

I dreamed of one day getting a 96″ x 60″ ShopBot PRSAlpha… and a few weeks ago, it happened.

The capabilities, coming from a ShopBot Desktop are truly hard to describe, this machine is FAST and precise!

I still have trouble accepting just how fast ShopBot Tools and bit suppliers are telling me what the feed speeds can actually be on this machine, it’s just so unreal compared to what I’ve been doing for the past few years with the Desktop model.

It’s like moving from a bicycle to a rocket ship – although a ShopBot Desktop is very much industrial, I cut A LOT of stuff through the years with it without any complaints, it does have its limits compared to a ShopBot PRSAlpha and even weeks later, I’m always astonished at just how much I can get done with this machine.

Thanks ShopBot Tools for not only making an amazing ShopBot Desktop for people like me who know nothing to cut their teeth on but for making a full sheet machine for when we outgrow the capabilities of the Desktop and want to get into full-scale production.

I never could have imagined I’d ever get a machine like this in my shop, for instance, the job above which I did with the ShopBot Desktop is done in a fraction of the time using the PRSAlpha, the time savings are substantial!

My next CNC router dream is getting a tool changer for this machine, I never really appreciated it with the ShopBot Desktop but for the ShopBot PRSAlpha, its really a must have.

Maybe it will take a few years or like the ShopBot PRSAlpha, literally happen over the course of a week thanks to a client with a massive project.

It just shows you how much can happen over the course of 10 years of self-taught hard work, being in a shoebox Korean apartment with literally nothing to make anything to running a full custom production shop.