Dr. Henri-Jacques Topf, Owner of Schneider Prototyping GmbH (Germany)

I find it interesting how some people that I request an interview from take weeks if not months to get back to me while others have just a few hours turnaround! What’s all the more fascinating though is that generally owners of large multinationals are quicker than local small shops! Efficiency and passion may be a key in the success these huge companies have achieved in the global marketplace. I truly appreciate Dr. Henri-Jacques’s answers – took him only a few hours turnaround! Awesome!

Key takeaways:

- Sometimes an idea at a board meeting can lead to a large multi-national company just a few years down the road!

- In-house diversity in expertise and equipment has it’s benefits with a broad set of clients.

- Find your niche and dominate it!

You can visit Dr. Henri-Jacques business, Schneider Prototyping GmbH, at http://www.schneider-international.net/en/production/.

Back in 1991, what made you want to start Schneider Prototyping GmbH and where did the name of the company come from? Today there are many companies offering rapid prototyping services but back then, the whole idea was very much a novelty that few employed.

Back in 1989 we were shareholders of Cubital, one of the 2 pioneering companies in rapid prototyping (today the IP of Cubital is in Objet, that merged with Stratasys some time ago.). after one of the board meetings the idea developed to use one of these machines in order to set up a service bureau and serve the European market. After finishing my studies one year later this is what I did.

Back in 1989 we were shareholders of Cubital, one of the 2 pioneering companies in rapid prototyping (today the IP of Cubital is in Objet, that merged with Stratasys some time ago.). after one of the board meetings the idea developed to use one of these machines in order to set up a service bureau and serve the European market. After finishing my studies one year later this is what I did.

The name is from our sister company back then. i never wanted a company on my name. that would have been awkward.

You currently employ over 200 employees across your production centers, how do you go about recruiting the best and the brightest and what are some of the challenges with doing so across different cultures and languages?

Usually head hunters/recruitment agencies. we don’t find the different cultures an issue, maybe because of my personal background (I am French, being born in Germany. My wife is Israeli, born in Russia and my children live in UK. I was always a world-citizen). Most of our communication is in English. We are no poets, but we all manage to make ourselves understood in English pretty well. The most important thing is TRULY understanding, that different cultures/races/religions are neither better nor worse, only different. After this you need to accommodate, just like to the personal advantages and disadvantages of people.

Over the past few years, you acquired and opened-up new operations around the world – following the growing needs and demands of your customers with plans of entering the Indian and Singaporean markets shortly. How do you go about investigating if there is enough demand to open a new production facility and how long does it normally take from making a decision to actually opening an office?

We have already entered the Indian market and have now 4 branches in India (Delhi, Chennai, Pondicherry and Pune). Usually, I go there and talk to people. I truly believe in talking to people. It is MUCH more informative than reading research compiled by someone in some office. Usually about 3-6 month. We actually know where we will go next. It is more a question of not overstretching our resources.

What is it about Schneider Prototyping GmbH that differentiates it from other rapid prototyping companies? What is your secret allowing you to experience such explosive growth?

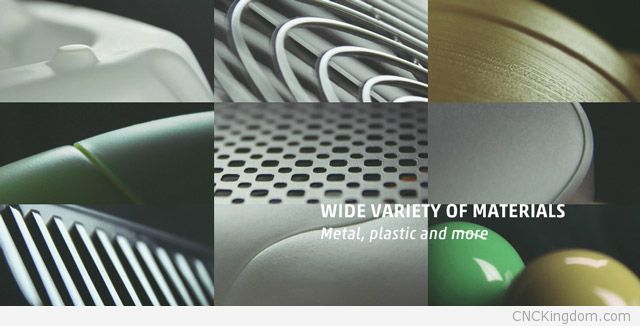

The main issue is our extremely broad range of technologies. We have all of these technologies in-house in our own production. this allows us to advise our customers impartially as to the best technologies. It also allows us to avoid problems very early on. We know from our own experience, what can go wrong. And our customers appreciate that we can give them the full service, from RP over prototyping of plastic parts and metal castings up to low-volume production in injection molding and metal castings, in many different technologies.

Which services do you provide are the most popular or most widely used by your production centers? What types of 3 and 5 axis CNC machines do you currently employ in your operations?

We do about half of our business in metal castings (mostly fully machined and documented) and in plastic parts. RP is only about 7% of our sales. Multiple machines. For new machines we have a tendency to buy DMG, as we feel very comfortable with them and have good experiences for many years. 5 axis machining is one of our core technologies, today more so than RP.

How much has the rapid prototyping industry changed over the past 22 years? How do you see this market changing over the next two decades?

Tremendously in some ways and not very much in others. Today RP is routine, reliable and price driven. 22 years ago it was exciting, unreliable and technology driven. But most of the media hype about “3D-printing” is not really so new and could also have been done 15 years ago.

The new 3D-plotters are unreliable and their products are useless (in our context of industrial technical prototypes. this is of course different for someone with other needs.) but this will change, as the technologies develop.

The market for rapid manufacturing will grow a lot, but this will be driven by the machine manufacturers, not so much by service bureaus. already now the machine manufacturers enter the low-volume production market, squeezing out their former customers with lower prices and larger capacities. But the material cost will remain high and I do not see this to enter mass production.

Low-volume high-cost markets (military, aerospace, medical, robotics, …) will be heavily influenced though. and of course it will be a great tool for inventors and educators all over the world, enabling normal people to do many things, that 10 years ago only big companies were able to do.