Dean Carpenter, Group Director at Lotus Laser Systems (UK)

Dean Carpenter has had, and continues to have, a successful and illustrious affair with CNC lasers from around the globe being both a representative for some of the top brands in the world and manufacturing his own systems! He was also the Chairman of the Association of Industrial Laser Users (AILU)!

He was very kind to give me a little time out of his day so that I could tap into his knowledge about the industry, it really changed the way I perceived things up to this point.

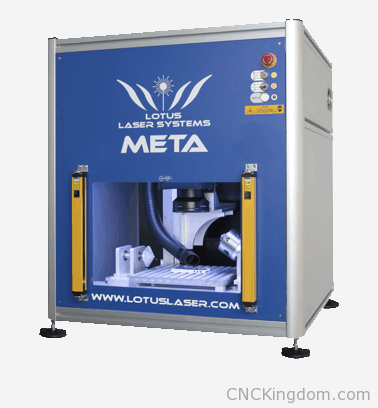

You can find Lotus Laser Systems at http://LotusLaser.com and Laserite Ltd. at http://www.laserite.com.

You started off your career being the UK distributor for Universal Laser Systems and then went into business manufacturing laser systems while becoming a distributor for other companies such as Trotec Laser. Can you give me an idea of what components are the most critical to have in a quality laser machine and which aren’t? If I had a certain budget that must be met… where should that money be invested in?

In terms of component grade (quality/reliability/performance) anything mechanical/electronic will always be a careful balance between what you get and what you pay. In this respect Lasers are no different to TV’s or toasters. This does not make machine better or worse because it’s all relevant to the application (the demands/requirements of the job) and price paid.

In terms of component grade (quality/reliability/performance) anything mechanical/electronic will always be a careful balance between what you get and what you pay. In this respect Lasers are no different to TV’s or toasters. This does not make machine better or worse because it’s all relevant to the application (the demands/requirements of the job) and price paid.

We call this balance FAR (Functionality/Affordability/Reliability).

One thing that we have to date never compromised with is the laser source. For this we have always ‘bought best’.

To set a budget for the machine is completely the wrong way to buy right. Unless you are lucky you’ll never get what you NEED.

Buying the cheapest machine is often the most expensive way to lose money but likewise, buying the most expensive machine is just as bad.

Why is it some CNC lasers cost an arm and a leg while others can be got for cheaper than a hobby CNC router? There is an incredible gulf between manufacturers – it can’t all be just because of components, is it?

Component grade is the biggest factor. In our starting models at 30w the laser source alone is worth well over £5k. Some manufacturers 40w machines use a laser they buy for USD290 (yes, two hundred and ninety dollars, about £175).

On the face of it you get 10w extra, right? Other factors are general design (performance/safety), support (some is great, some non-existent – support has a value) and some manufacturers hide essential things (like packaging) and slip the costs in later on in the sales process.

When you design custom solutions for customers, what are the key points you need to uncover from them and what are some of the mistakes you see people making when acquiring a CNC laser?

We start with identifying the customer requirement NOW and then make a calculation for what they may need in the near future. We access their site circumstances and even their market conditions.

For some customers we even review their business plan (the part that involves the laser). What comes-out of this consultation process is what they NEED in terms of a hardware/software solution and as a consequence we have a price.

Across all the CNC lasers you represent and manufacture, what are some of the activities performed by your customers that can dramatically increase or decrease their ROI and the life of their CNC laser machine?

SPEED, RISK, COST. No matter what you do it’s all about minimal cost, minimal risk, maximum speed. In some cases a machine costing £50k can be a lower cost, lower risk investment compared to a £10k machine.

Ultimately, my measure of a machines success (commercially) is how much profit it can generate PER HOUR and then how many HOURS it needs to be run to repay 100% costs.

What advice would you give to somebody looking to enter the CNC laser field?

Minimise your risk, maximise your opportunity: success is then inevitable. Base your application around business systems and not around people. Do not be a J.O.B. business.

How much as the CNC laser field changed over the almost two decades you’ve been in it? Can you give some concrete examples of what you had to deal with then which isn’t even a thought in today’s customers? For instance, you no longer need to know g-code to run a non-industrial CNC laser machine.

True technical skills re the kit are absolutely not required these days but only if you buy from a company with a decent support resource. Factor into your costs fixed annual maintenance contracts and under no circumstance DIY maintain except for cleaning.

True technical skills re the kit are absolutely not required these days but only if you buy from a company with a decent support resource. Factor into your costs fixed annual maintenance contracts and under no circumstance DIY maintain except for cleaning.

Concentrate on understanding the fundamentals of the system and don’t get lured into relying on technology that babysits you. Click and go is the worst and unfortunately a lot of systems have leaned towards such design these days.

By doing that you learn nothing. Understand the true abilities and limitations of the machine and don’t believe all of what you see is sales guides, web sites or even internet forums. The keys to success today are firstly selecting the right tool for the job and secondly applying it to work in a profitable way.

Can you describe why achieving an ISO 9001 is so important for Laserite and what it means for your customers as far as doing business with your company vs one that isn’t ISO certified.

ISO doesn’t necessarily make one company better than another as we are the same company today, same people/processes that were in place in Nov 12 (before ISO9001), however, it certainly helps to have an independent and highly skilled quality assessor double check what you are doing.

ISO doesn’t necessarily make one company better than another as we are the same company today, same people/processes that were in place in Nov 12 (before ISO9001), however, it certainly helps to have an independent and highly skilled quality assessor double check what you are doing.

Once you have the ‘badge’ it proves to the outside world that the company has been bothered enough to spend considerable time/money towards gaining certification. It also cements into the culture of the business the importance of quality control.

Often, quality is an important factor at management level but as you trickle down the chain of command it can get lost as being a priority. With certification it makes the whole company aware, alerted to the importance of QC.

Anything else you’d like to add?

The biggest killer of opportunities today is, in my opinion, misinformation. Just because something is on the Web does not mean it is correct. Wikipedia is a classic example of this. All businesses survive through profit and the bigger the business the more profit it needs to make. Therefore, quite often the biggest perpetrators of misinformation are the larger companies who peddle misinformation because it suits them to do so: it’s more profitable.

One of the biggest frustrations I have is seeing people being miss-sold. The only thing worse is when I see/hear a customer defending their supplier after being miss-sold. I see it all the time where someone has bought the wrong kit but they will use their last breath to defend their wrong decision.

Example: I was in the US and a helicopter manufacturer walked onto my booth. He was looking for a marking laser. His need was marking serial numbers to parts. He had x9 lasers from his preferred supplier. The first laser did the job great so he went back and bought another. He still couldn’t meet the required throughput so he repeated this process until he had x9 machines but that still wasn’t enough as the business was growing fast. He happened by chance upon the show I was at.

He showed me his application and I could have done it with x2 of our machines for an investment of about £50k. He had paid about £225k for his x9 machines. The point is that there were several other BIG companies all trying to sell him the same machine as the x9 he had bought so by definition the one telling him different had to be wrong, right? This is not an exaggerated example.

Here’s another; a firm down the road to me came to me last year and told me they want to cut and engrave. I proposed to them x2 totally different machines with a sum total of about £48k. He chose to buy x1 machine (a hybrid) that could do all jobs, a kind of Swiss army knife of the laser world. Guess what? He won work through samples he made but he cannot afford to do it because his machine is so slow! Ironically, he’s now sending us the work to do on a sub-con basis as it’s cheaper/faster for us to do it for him then for him to DIY: crazy.