My Criterial for 3D Extrusion Designs: no supports or assembly

So far from experience, although my 3D Systems Cube is capable of producing support material (same as the model build) I’m trying to come-up with designs that don’t require any of it. To make things even more difficult… I don’t want to design models that require any assembly either… there is already enough of that in the laser, table router and plasma department here on CNCKing.com.

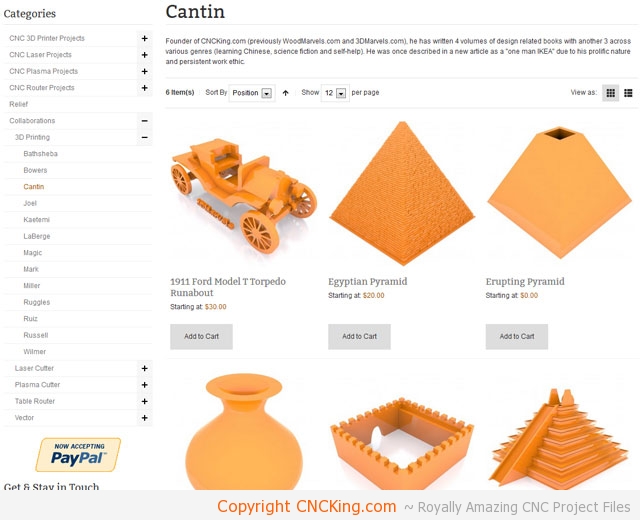

As these are my criteria, I’m trying to come-up with about 50 designs of things that are useful and maybe interesting enough for somebody to buy from the site… it isn’t easy… dare I say that it’s far more difficult than designing for CNC lasers or table routers by none. I’d love to design a whole bunch of amazing 3D printed toys but it won’t happen with my Cube – I knew that going in so to me, the challenge is making something despite all the limitations present in the technology.

All that being said, I have come-up with some things that I consider pretty darn good… far better than my first laser designs so there is hope now that I fully understand the capabilities of this robust little Cube.

The first model you see here is impossible with my Cube, I need a high-end 3D printer to make this all in one shot and in working order but the others – agreed, not mind blowing – are far better than one of my first laser projects below.

So far, I’ve designed 6 working projects that have been tested and proven… only need to come-up with another 44 to reach my goal with my 3D Systems Cube. I finished-up a print the other day that came out amazing by the way… hopefully it’s done rendering by tomorrow so I can launch it here on the site.