Charles Baird, Industrial Design Intern at Techtronic Industries (Australia/Canada)

When I went to University, I studied a double-major in Biology and Geography… when I graduated, there were no jobs for me so I created my own industrial 3D animation studio and spent years visiting shop floors across North America. Long story short, looking back, I wished I had discovered this passion when I was younger and studied engineering instead but back then, I didn’t know much of anything about it.

This is why I approached Charles go give some insight about his studies in Industrial Design and to create an even larger ark, that’s why I developed CNCKingdom.com after years of building CNCKing.com to give me the knowledge and contacts I didn’t have growing-up and sharing them with others. If I would have had these resources growing-up, my path probably would have been very different in life.

What aspects of industrial design interested you before heading to University full-time to get a degree?

I decided to study industrial design whilst working in the warranty department of a bicycle shop. I liked some of the products but thought that I could do better than some of them too.

I’m entirely self-taught but manage alright with CNCKing.com – can you give me an idea of what a typical semester is like – what you learn and how relevant you find the knowledge you acquire to the real world?

There really is no typical semester. The only continuous subject is studio where you work on 1-3 briefs a semester and integrate what you learn in the other 3 classes in a semester. There a lot of skills to learn though: research, ideation, brief writing, CAD, design for manufacture, rendering digitally and sketching by hand, brand positioning and product definition to scratch the surface.

I use Autodesk 3DS Max for all my design work but I know SolidWorks is by far a superior design solution – what was the learning curve like when you first began using it and how long does it take to become proficient in it? What to do you like most/least about SW?

The learning curve depends a little bit on general computer skills but I’d say 3 or more years at least. I’m still learning every time I use it. Sometimes I might learn an improvement in efficiency or a better way to control surfaces, other times it might be a better way to render. Plus it’s always being improved so there are new techniques to learn each version.

The thing I like the most about SolidWorks is that it’ s a parametric modeler. This makes drawings and assemblies far simpler than they’d be otherwise. The thing I like least about it is the more limited surface finishes than some other rendering programs.

You recently had an internship at Techtronic Industries, can you give me an idea of how you got it and what you did while you were there? How was the overall experience and what are some of the projects that you worked on (that you can share?)

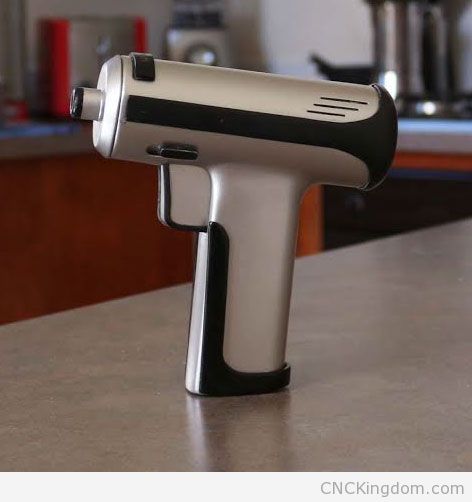

The opportunity for the internship came from Sandy Walker, my university lecturer. While I was there I spent the majority of my time using Adobe Photoshop and Illustrator on a Wacom ideating and rendering concepts for various projects. I also spent a lot of time researching the projects I worked on and establishing the target market. The overall experience was fantastic and I learnt more about industrial design in 2 months than I would ever be able to at university. I worked on a laser level project, a construction site radio project and yes there’s one project I can’t talk about yet!

Out of all the machines you get to play with in university, which CNCs do you enjoy the most? 3D printer, plasma, router, tig, laser etc…

That’s tough question. I really like all of them but for different reasons. I like the 3D printer for creating realistic molded plastic parts. The CNC router and laser cutter are fun and can be very creative. With the router and laser cutter you have the chance to create a finished design with little finishing. Unlike preparing and painting a 3D printed part! Also my brother has his own 3-axis CNC router and we’ve both learnt a lot about design for manufacture whilst scratching our heads and problem solving design intent meeting physical constraints.

How easy has it been for your colleague to get gainful employment in the industrial design field? I know a lot of companies are off-shoring this expertise to Chinese and India firms.

Well not very so hard. I know of 2 other people from my graduating year with jobs but it’s under a month since I finished the degree. I think that there will be fewer local industrial design jobs in the near future as jobs are moved off shore and people follow them. It will be interesting to see if some of those people then come back and work here. Rapid prototyping, video conferencing and a willingness to travel might create an advantage for design being located amongst its users.

Are there any specialties you want to focus on within industrial design? What do you see yourself doing upon graduation in your dream job or starting your own firm in?

Well my focus from the start of the degree has been a job designing outdoor equipment, apparel or cycling equipment and that’s still the dream. I do have a few ideas of my own which would be relatively cheap to try so we’ll see what happens. I would love to see an idea be developed from scratch to a manufactured product that people can buy.

What are some industrial designers you look-up-to for inspiration?

Tinker Hatfield the designer of the Nike Air Max 1. He was inspired by the Centre George Pompidou to show the function of air bag in Nike sneakers. Other than that a lot of the designs I really like I’m not sure who designed them; as is often the way with industrial design. But I really like the work of Arc’teryx and love the design of the last 40 years of road bicycles. You can track a lot of innovation in manufacturing through them.

Anything else you’d like to add?

I’d like to thank the teaching staff at the University of South Australia in particular: Sandy Walker, Dan Mclean, Anna Brown and Peter Schumacher. I’d also like to thank the friends I’ve made through the course, in Australia and Canada, for being great friends and teaching me a lot. I hope that’s been reciprocal. Finally I’d like to encourage anybody thinking of studying industrial design to do it. It is what you make of it and there are so many skills and niches that there is something for everybody.

You can contact Charles by visiting his LinkedIn profile page at:

http://www.linkedin.com/pub/charles-baird/3b/8a7/a99