Casey Perritt, Founder of CNC fabricators (USA)

I’ve been following CNC fabricators on their Facebook page for quite a while because I love the work they are doing – it’s some of the nicer work I’ve seen in the CNC plasma field that’s within my abilities once I get my own.

You can find them online at http://cncfabi.com and be sure to visit them on Facebook at https://www.facebook.com/pages/CNC-Fabricators-LLC/177849585695779

I’m not sure how I fell upon your site but I’ve really enjoyed seeing the CNC plasma projects you make. How long have you been designing for plasma and what is it in your background that allows you to make such awesome work with it?

Thanks, I’m just glad people like the products and artwork I’ve been making. I’ve been doing CNC plasma work for roughly 2 years now, first working in welding and fabrication shop then later I started CNC fabricators LLC after I decided to go out on my own. I have done architectural blueprints and mechanical drawings since the early 90’s and is also what I have a degree in.

I learned G and M code pretty early on since the computer aided drafting program works off the same coordinate system. I worked in production at a titanium & nickel alloy tubing plant then later for the Institute for micro and nano manufacturing at Louisiana Tech (local college). I have 12,000 drawings since 1993 so I guess I enjoy drawing things. Once I realized I was fast and proficient with Cad I completely stopped drawing on paper.

When ever I see your fire pits, I get greatly inspired to make my own (once I get a CNC plasma). I was wondering how long it takes to cut a typical fire pit and what processing is required afterwards to go from a flat sheet to a round one. How long from rolled steel to finished working fire pit?

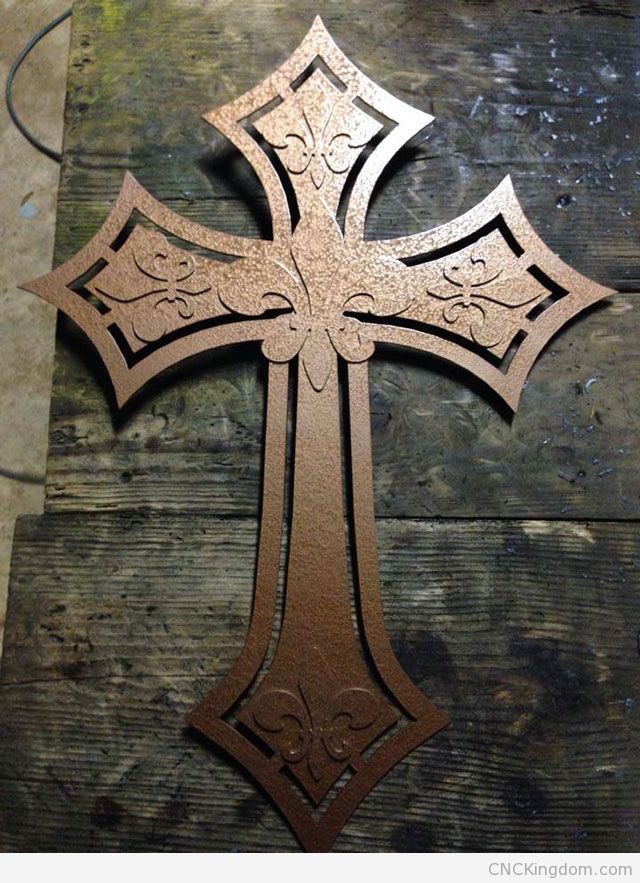

normally it takes 4 to 6 hours to generate a complete custom drawing for one of my standard fire pits. It all really depends on the detail the customer wants and if I can use parts of other drawings I can use to finish the drawing faster. My standard fleur de lis fire pit has a total cut time of 1 hour give or take a few minutes either way. Once all the pieces are cut, the dross/slag left on the backside of the material is cleaned off using wire wheels and flapper discs.

The base is formed in a slip roll for rounding plate steel into a tube. All the welds are the same distance apart and are all hidden on the underside (where we can) for a cleaner look. Soon after the pit is sandblasted, painted with high temp paint or high temp powder coated. Then they are ready to ship or deliver. I’ve made 3 to 4 a day for 6 days once with two helpers. Not a fun week. Under normal circumstances it usually takes 5 hours to complete a fire pit.

I really like the raised lettering and designs you make – it really makes the design pop! How is that accomplished without simply doubling-up the same parts but keeping everything strong enough? Do you just weld small pegs or is it a slightly smaller version of what’s above it?

the 3D look was a very happy mistake I made on day trying to decide how to bond the two pieces together. I dropped a handful of 3/8″ hex nuts on the back piece of a college logo I had just cut out and wasn’t paying attention to where they were laying. I placed the front plate on top of the back piece and it looked really good spaced apart so I had to figure out a way to bolt them together.

When I make the drawing I draw holes the size I need in places that will provide support to the metal, after the pieces are cut out I tape the bare metal together after it’s been cleaned of dross and get it into position and where it needs to line up. I simply flip the two taped (painters tape is the best) pieces over and trace the holes with a sharpie that are cut on the back plate. Remove the tape and weld hex nuts to where the traced circles are. Bolt together and trial fit each piece before painting and that’s about it. 3D metal signs made to last.

I really liked your Superman logo but what really made it special was the paint. Can you describe to people how you painted the steel (equipment used), if any polishing is required and how you got such a vibrant color. How long does paint on steel last?

The Superman logo is probably one of my favorites so far. The back plate was painted gold and clear coated with automotive paint. The logo was also welded in the same manner the 3D signs I makes.

The front pieces were primed, wet sanded, painted gloss black and let dry for 5 minutes. Then sprayed a really thick coat of red hand hammered paint. It starts to fisheye and the black under coat is exposed I wait 10 to 15 minutes to spray a bright red top coat over the other layers of paint.

Place in an oven and bake at 150 degrees over night so all the layers will dry properly and not smudge when touched. Then a uv resistant clear coat is applied to protect the paint. If the piece is kept inside an office or house it should be good for 10 to 20 years without any problems.

Who’s the manufacturer of your CNC plasma cutter and what other tools do you use on a regular basis to help create your designs? What types and thicknesses of metal to you enjoy using most and why? Do you have any other CNC tools in your shop? (laser, router etc.)

I have a torchmate 3 axis 4’x8′ table with a hypertherm 65 plasma cutter and a wood router attachment for the table, 3 axis CNC milling machine, 3 axis CNC laser cutter and engraver with rotary attachment for cutting or engraving round objects. A slip roller for rounding plate 4’x8′ max size. 2 sandblasting cabinets and 2 outdoor large sandblasters.

A 4’x8′ powder coating over, a Gema optiflex powder sprayer, a full cabinet of standard metal working tools, I also have a hand held torch for the plasma cutter. I use Autocad design software for all drawings. And a bunch of other tools, too many to list.

You have a lot of college logos and designs but two projects really stood out for me, your Zombie Blade MK1 and your Texas Boot Table. Where did those ideas come from and in general, how do you find clients for your business?

the zombie blade was from a picture I saw online of a blade some random person had made. I changed the design a little and made my own. I actually have 3 designs and one is an axe with interchangeable heads, like a spiked ball and a mace. I will post pictures soon. My patent the items also.

My old boss asked me to design and make a table that screamed TEXAS, so that’s what I tried to do. He came out and looked at it and said I don’t get it and I don’t like it. I was a little put off but everyone else that’s looked at says it screams Texas. It has a lone star, a outline of Texas taken from a usgs map for accuracy and two huge pairs of cowboy boots with spurs to top it off. It’s probably the only thing I’ve made that someone didn’t like so far.

I’m working on a table with a Louisiana theme at the moment and will grace my back patio at a future date.

You mention in your company description that you also do wood projects – can you share a few pictures of the work you’ve made and describe the work involved in creating them?

With all the metal projects and powder coating I’ve been doing, I haven’t had the time to get back to making wooden pieces. I’m planning to combine metal and wood together in one of my pieces soon. I’m building a coffee table for my man cave and will be using CNC cut wood and metal parts. The table will be Han Solo in carbonite from the original Starwars movies.

It will appear to be floating when it’s done. All the pieces are cut and I have a cast of the front piece from the original set piece so all I have to do it put it together and probably 80 hours worth of sanding etc.

Anything else you’d like to add?

Thanks for the questions, I enjoy explaining the process of making my products and teaching others a skill they can be proud of. I believe I’ve finally discovered what I want to the rest of my life. It’s a dirty job but at the end of the day you get to say “hey, I made that” and that really puts a smile on my face.

I hope to be able to afford to do some charity donations of my products soon as well. I guess that’s about it. I’ve done all this by trial and error and it’s a little easier when you know someone that’s been there and done that. Have a good one.