Brendon Vetuskey, Design Manager at Mattel (USA)

I’ve always wondered how the design process is handled in big toy design firms such as Mattel… they come-out with an endless array of awesome products across such a wide variety of licenses and Brendon was kind enough to help shed light on it all.

Key takeaways from this interview include:

- Follow your passion and it will lead to opportunities you can only dream of!

- 3D printing and other advances in manufacturing and design have helped the toy industry tremendously to reduce the product design cycle.

- Design for the consumer who’ll end-up with the finished product – no point designing a 100$ toy if demand is for a 20$ toy and allow brands themselves to dictate their design direction.

You can contact Brendon via his LinkedIn profile.

I have to tell you, much of my childhood was spent playing around with Hot Wheels and Lego, the two went together so well! Being the design manager for these addictive little toys that all young boys collect, how do you go about deciding what gets manufactured and in how much quantity?

Actually, I don’t. Vehicle selections are handled by our die cast design management and the assortments/ quantities are handled by the die cast marketing team. I’m the design manager for Hot Wheels entertainment branded product. I help oversee the design and development of licensed product like Monster Jam branded play sets and replica trucks, Marvel branded track sets and character based die cast cars, etc.

Actually, I don’t. Vehicle selections are handled by our die cast design management and the assortments/ quantities are handled by the die cast marketing team. I’m the design manager for Hot Wheels entertainment branded product. I help oversee the design and development of licensed product like Monster Jam branded play sets and replica trucks, Marvel branded track sets and character based die cast cars, etc.

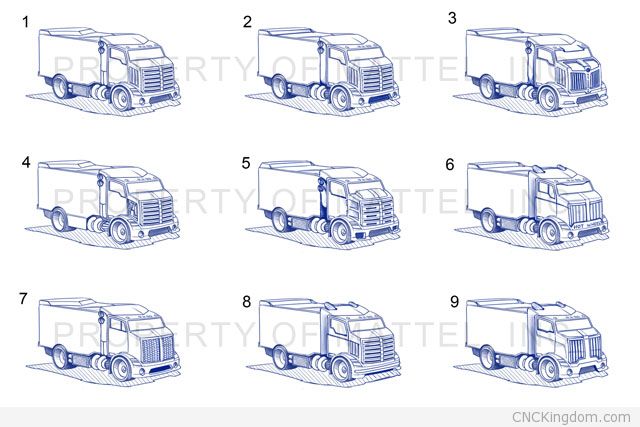

I have been fortunate enough to help the die cast team develop over twenty five different 1:64 scale Hot Wheels cars, as well as nine different 1:43 and 1:18 scale die cast vehicles for the adult collector lines. However, the vehicles and licenses are already chosen by those who oversee those lines, I volunteer my time to help with designing the product.

Which Hot Wheels are your favorites and how long does it take you to design one from initial sketch to finished manufactured piece? Any idea how many have been manufactured in total and how many unique Hot Wheels there are out there?

I have many favorite castings including: “Custom Firebird”, “Rodger Dodger”, “Large Charge”, “Alive ‘55”, “Greased Gremlin”, as well as a couple I have designed including the “1967 Pontiac Firebird 400” and the “1955 Chevy Bel-Air Gasser”. There are many factors that affect the actual development time including if it is licensed/ approvals, which product line(s) it is for, and overall urgency of it, to name a few examples.

As for quantity, there are many more than I could count, and the amount of unique would depend if you are counting just the basic 1:64 die cast, or including the variants- (sizzlers, Farbs, Scorchers, Crack Ups, Cap Blastin Racers, Billionth Car collection, XV Racers, Atomix, Micro, G Machines, 1:87th, 100%, Elite, to name a few, etc.) I’m sure it’s well into the thousands.

When you graduated with your BFA in Industrial and Product Design from the Cleveland Institute of Art, what did you think you’d be doing 10-20 years later? Was kids toys always on your list of things you enjoyed working with and developing?

I started out in school thinking I’d major in transportation design, and felt I had an advantage as I’m very passionate and knowledgeable about muscle cars and hot rods (and cars in general), yet it was also a hindrance for me. I would design cars that were essentially muscle cars and hot rods.

While realizing this wasn’t working out I had an early success on another project in school where I took a consumer product project and made a cool toy out of it. That summer I had an internship at a local design consultancy known for making toys, and the summer after I interned at Fisher-Price. I was hooked on toys ever since. These days I’m quite fortunate for being able to combine my passion for muscle cars, hot rods and toys all at one place.

I’ve designed over 250 CNC projects (laser, router, 3D printer) and it just never gets old… there is always a new challenge to overcome. How much have Hot Wheels evolved over the time you’ve been there? I know the packaging is much nicer now and the amount of detail is far more precise. What tools do you use to prototype and build them in the shop?

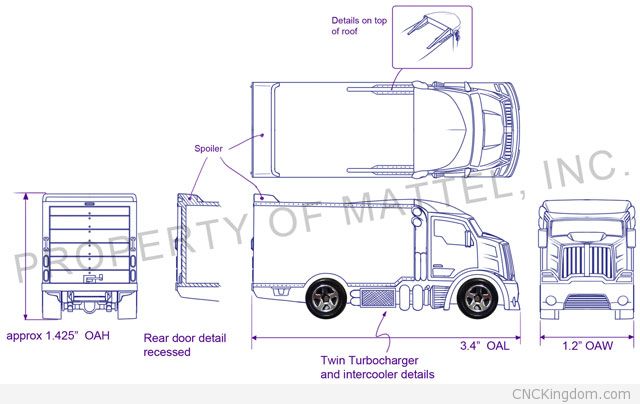

Hot Wheels cars have benefited from technology for both accuracy and reductions in development time.

In the beginning patterns were carved out of wood at about four times their scale, and they would pantograph them down for tooling. Working at different scales can affect the final design as changes in a larger scale are diminished when it’s scaled down.

These days they are sculpted at 1:1 scale on the computer and can be quickly 3D printed for a 1:1 review. We make changes in thousandths of an inch and finesse the details until it’s just right. Digital files can also be electronically transferred to and from the factories saving on shipping time and costs.

You also manage other brands until Mattel from Max Steel to Marvel and Monster Jam. What are special design characteristics that you build into models that make them both attractive to kids and long lasting?

This is my primary responsibility, ha ha. I think it helps to understand the brand and consumer base that you are working on. As one example- I have been a long time monster truck/ Monster Jam fan. I attended monster truck events as a kid and I still attend the Monster Jam events here in Los Angeles, as well as the Monster Jam World Finals held in Las Vegas each year.

I am active on a few Monster truck related forums and read what the collectors/ consumers have to say. We also work with our Consumer Insights department to help provide us research as a tool for additional feedback from kids and consumers alike.

How much creative freedom do you have when designing for a specific brand? There are so many directions you can take – how do you decide which is best and will be the most profitable for all involved?

I think the brands themselves help drive the direction. Using Monster Jam as an example again- to make a compelling play set it’s good to know about the brand. Fans see monster trucks perform (jumping, racing, crashing, stunting, etc) mostly in an arena setting, so it makes sense to focus a play setting in an environment doing the types of things that monster trucks do.

Now the challenge becomes making each new set still compelling and different enough for the consumer to keep coming back. We need to make sure we are making the set exciting enough for the older child, yet still simple enough for a younger child to play with and making sure the toy passes all safety requirements. We need to make sure the products are manufacturable. We also have approvals needed by both our management, and by the licensor(s).

The packaging needs to get the consumer’s attention and tell the story quickly, especially if there isn’t a commercial selling it in. We have costing to consider. We design the best product possible within the cost targets we are provided.

The coolest $100 set in world isn’t very useful if the request is for a $20 set. Last, but not least, is the schedule. We have to develop the product on time. We need to balance all these factors in. It’s more difficult than I think people may realize, but even with all that it is still a lot of fun and I couldn’t imagine doing anything else.