Brad Moore at Cirri 3D Scanner (Canada)

The goal of Cirri is to transform your phone or camera into a fully fledged and high quality 3D scanner. They are running an indiegogo campaign right now at http://www.indiegogo.com/projects/cirri-3d-scanner-professional-quality-3d-scans-from-a-camera-or-smart-phone

Can you give me a little background about yourself and how you got into software development?

Can you give me a little background about yourself and how you got into software development?

I was involved in small technology companies focused around embedded controllers and automation. Eventually I became owner of company that designed, built and sold CNC machinery and control systems. We had distributors in 25 countries and place machinery in over 60 countries.

Through the CNC world I became fascinated with 3d scanners and 3d modelling. Over time my interests became solely focused on ways to bring 3D from the dedicated professional realm into a more part-time occasional usage realm. I looked at a Cirri type product in 2005, 2008 and again in 2011, but it was like pushing on a rope. The necessary infrastructure was not in place.

Just in the last year or so 3D printers have started to plummet in pricing, even the most basic computer now has processors large enough to handle large calculations, and we’re seeing new and capable 3D viewers that can open display 3D content on almost any website. So it’s all happening right now. Thus we decided to launch Cirri.

I clipped this from my bio

Brad Moore brings an extensive management background to the CIRRI team. He has been an active participant in the development and marketing of 3d measurement and visualization technologies, identified and pursued technical developments and market conditions leading to the formation of CIRRI. Brad was twice nominated for the Ernst & Young Canadian Entrepreneur of the Year award while CEO of a Western Canadian based company that developed, manufactured and sold industrial cnc machinery and computer based manufacturing solutions with installations in 60 countries worldwide. He has hardened experience to achieve profitability and stability with both technology startups and established manufacturing companies. His companies have been the recipient of many awards including the Calgary Export Achievement award and the Coolest Business in Alberta award. Brad is a McMaster University Letterman. He has lead companies to eight figure valuations and facilitated business owner exits leading to multi-million dollar payouts.

Cirri looks awesome, there seem to be many solutions where you scan using “any device” to produce a 3D relief that can be CNC’ed afterwards. Generally speaking, the results are poor, what makes your software different and able to generate higher precision/dense point clouds?

That’s our special sauce. Cirri is based on a modified scanning engine from my business partner in Cirri, Gary Robertson, a pioneer in the field of close range photogrammetry.

ShapeScan was first developed over two decades ago when Gary determined the current best technology couldn’t give him the results he needed for scanning components of jet fighters. So he just invented a whole new way of doing it. And his 3d scanning engine has been evolving ever since, staying far ahead of any other solution out there. It uses a variety of techniques and special algorithms within the software engine to derive the measurements. The exact same engine drives Cirri. It’s got quite a pedigree.

What problem are you trying to solve that the market doesn’t right now with Cirri?

The fact is 3d is a helluvalot harder than 2d. It’s why we’re not there already even though we live and interact in a 3d world. My goal is to make 3d as easy as 2d. That’s a long term goal and will require a long term development, extensive adoption of artificial intelligence and lots of input from users to direct development down channels that lead to specific solutions. And in my view a solution means increased utility.

Right now I just don’t see a 3d scanning solution that can produce a 3d model with enough quality that it truthfully represents the real world, offered at a price that makes business sense even if you only occasionally use it, and is easy and straight forward to use. That’s step one. Without that 3d will continue to disappoint the “casual” user as it has so many times in the past. The next steps involve completing the solution paths down specific application vectors.

You have quite a diversified and incredibly talented team involved in your Indiegogo campaign, how did you convince all of them to join-up with you?

Yes we really have the best of the best. Our team are the innovators and the experienced veterans at the same time. There is real messy haired eccentric genius within the team. A lot happening in 3d scanning right now, but if you really look at what technology is driving that activity it comes from a super tiny pool.

We’re not big but our pool is the deepest. I’m lucky enough to have worked alongside each team member over the years. We all have the same objective and now seems like the right time to make sure our technology gets used to help move 3d forward with a happy ending to the first chapter, then on to the next.

Cirri can be used to generate models for 3D printers to CNC table routers and laser engravers, how did you go about testing your software across such a large variety of CNC machine types?

As I mentioned before I came from the CNC machinery world and became well acquainted with dozens of CADCAM software. So I know that if the software can import and put a toolpath on an stl file type, which is the most common 3d mesh file used in CNC, then the software can use the output from Cirri.

I also know that the most common softwares that can import an stl file type already have drivers to output g-code that can be understood for the hundreds of flavours of CNC machines and machine controllers out there. So by default if they can open a Cirri file that makes Cirri compatible with almost all CNC machinery.

What are your thoughts on IP and copyright? Scanners are a wonderful tool but they also open a huge Pandora Box, allowing anybody to, within a few minutes, scan and replicate what can take a designer weeks if not month to build.

Yes, that’s mostly true. The same argument I’m sure existed through the various stages of humans replicating the real world. There’s probably still a pissed off caveman haunting some cave somewhere.

I’ve worked with people today who’s religion won’t permit their photo being taken. I for one welcome our overlords. I find 2d really boring. I see my three boys with their eyeballs glued to flat monitors viewing flat pictures as I type flat letters on this screen right now. It’s so irritating I could scream. I can imagine something far better. It would be a shame not to try my best to move us toward that imagination.

So far you have raised about 7% of your intended goal of 55K. What is the biggest challenge you’ve found with crowd sourcing software?

Well I’ve never done it before. So there is a learning curve. I usually am best when I can talk to people and explain things and respond to their concerns. On the crowd funding site I don’t get that chance so I need to explain it all upfront without melting peoples’ brains with boredom, or have the crux of the matter get lost in all the stuff. That’s pretty tricky. Then of course you’ve got to get the work out. Hopefully this will help. The crux, by the way, is you’ve got to start from a position of a high quality, dense, accurate scan.

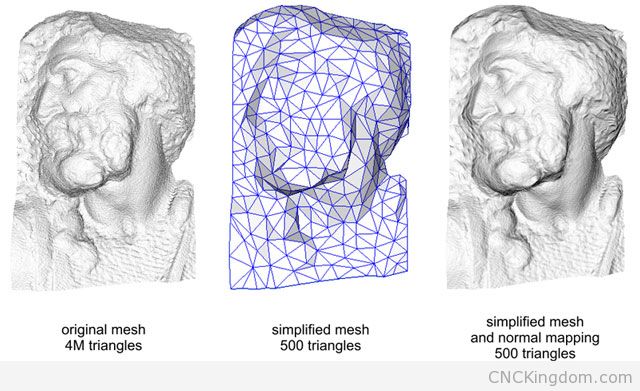

3D printers need it, CNC’s need it, movies need it, archeologists need it, and so on blah blah blah. Even video games need it, even though most of that detail will be removed to make the file small enough to be useful in the game, the visual essence of that detail is preserved in a normal or height map, and the only way you can generate a quality normal map is by starting with a quality high resolution 3d scan (there’s an better explanation on the indiegogo campaign about that).

What distribution channels are you looking at for Cirri? Do you plan on making it available only on your website or do you want to get into physical boxes and into stores?

Initially we want our delivery system to be all internet based, but our sales channels will be a combination of direct from our website and value added resellers. I’m really big on the value added reseller. Basically what that means is Cirri is one component in a solution that get’s the customer from point A to point B.

On its own Cirri doesn’t have much utility. It’s cool for sure, but then what? But as a foundation scanning product, because of the quality, accuracy and density of the point cloud – and the cool stuff we do with texture and stitching – Cirri opens up a world of 3d happiness not possible with the sensing scanners or other that limit your scan size to a pop can or less.

Cirri scans from a distance of centimeters to kilometers. A good reseller can put together very effective solutions for end users.

Anything else you’d like to add Brad?

Yes, of course. Please sign up for a Cirri scanner while the campaign is still on. It’s an astoundingly good deal and you’ll be furthering the cause of 3d to the benefit of everyone. Visit Cirri’s indiegogo campaign right now at http://www.indiegogo.com/projects/cirri-3d-scanner-professional-quality-3d-scans-from-a-camera-or-smart-phone