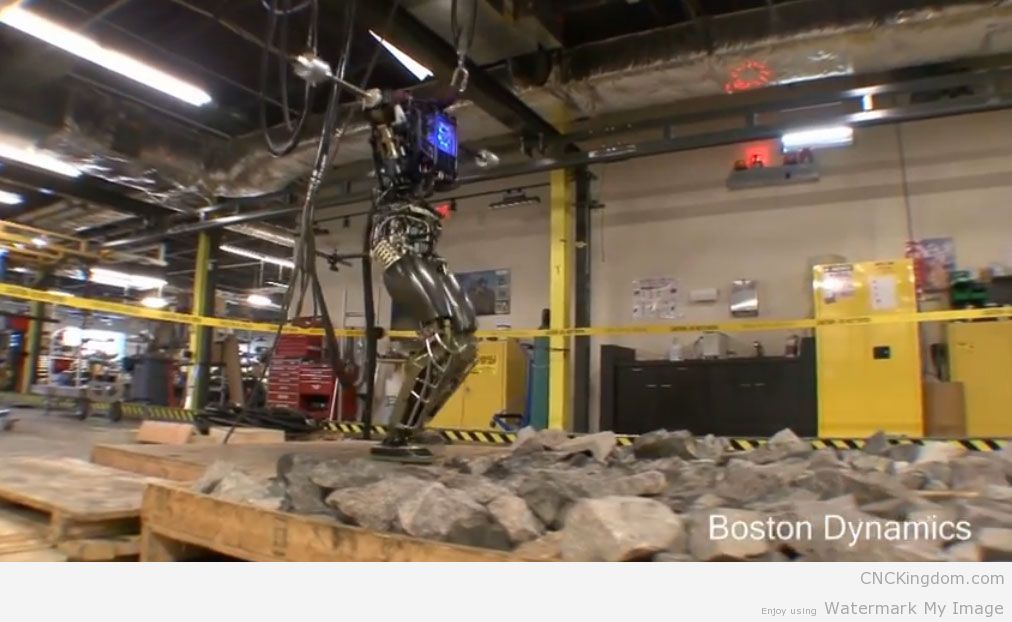

Boston Dynamics Atlas: The Future of CNC Machines (USA)

What are the ultimate CNC machine? Humans… their “computer” is endlessly configurable and more creative than even the most powerful processors. Their dexterity and bidirectional feedback mechanisms are unmatched and the tools they are capable of making themselves across almost endless combinations of axis produces some of the most amazing machines.

There is are some severe limitations to the human design though. They are prone to breakdown (mentally and physically), they are easy to injure and take long to recover and unlike machines… their evolution isn’t exponential. A human physically 60 000 years ago will be the same human design 60 000 years from now but a machine designed today will be exponentially smarter, stronger, faster and creative just a few years from now. We are never going to be able to evolve, even with massive genetic enhancements and cybernetic implants at the same speed a machine can.

Welcome to the future of manufacturing… just because 99% of the CNC machines out there use a gantry system doesn’t mean it’s the best design… THIS IS! Why? Well, imagine having a thousand of these on a factory floor working perfectly in sync, some with plasma arm/finger tips, some with integrated routers and who knows what else. This would be the most efficient floor ever… these Human 2.0s would work 24/7, never tire, would be easily upgraded with new skills in a matter of seconds instead of years and their work would be flawless. This is your competition and there is no way you have a hells chance of beating it.

What this video and many like it demonstrate is that we’ve now been able to create the perfect human to work, play and fight our wars… don’t underestimate the impact a whole division of these could do in a company and make no mistake, I’m sure this is seriously being evaluated RIGHT NOW in corporations around the world. You think Chinese workers are cheap? They need breaks, go to the bathroom, get bored, eat rice… these guys? No complaints EVER and will work for free (probably leased to the factory for a percentage of ROI)! They can lift repeatedly 10x their bodyweight and if they break, switch-out the broken bits for the fixed ones and they’ll go right along doing their work without PTSD.

The future that my kids grow-up in will be incredible, but if you go to school RIGHT NOW, this isn’t even a concept in the teacher’s minds… this will happen VERY FAST and if you don’t know programming (the second language all children MUST know) and you aren’t comfortable with machines, you are in for the unemployment line in 10-15 years time.

You might think you are safe… no job cannot be replaced with these guys. Delivery? Use drones… they are faster and don’t stop at traffic lights. Sports? Well, these guys can make any PRO look like an amateur. Basket weaver? Well… if your job isn’t already in China, this guy can make those baskets in a fraction of the time and at higher quality – not only that, they have a database of 10 000 designs that can be mixed and matched seamlessly. Teachers? Well, we are already a commodity and will only keep decreasing in value.

Each time I boot-up my computer and make something with one of my CNC machines, I think of myself as using the equivalent of a miner whose only tool is a pick-axe and intuition to find gold in them hills. There is no way I could compete with a mining company removing whole mountain tops. When you realize how fast and exponentially this CNC growth curve is going, it’s both scary and fascinating.