Andrew Berno, Industrial Designer & Owner of Fossick Designs (Australia)

Andrew Berno is a very ambitious Industrial Designer who enjoys a challenge creating new products such as his awesome Surf Ski concept to a chair made-up of three materials that don’t tend to stick together rather well. He’s very much doing what he loves and his designs only give a glimpse at his incredible creativity.

Key takeaways from Andrew’s interview are:

- Once you find something you enjoy and receive great pleasure from doing, it isn’t a bad idea to follow-through and transform it into a career.

- Starting your own business is a great way to fund what YOU want to design while at the same time, giving you the resources and time to help other firms with their issues.

- There is no easy way to learn software, you have to just keep practicing and learning!

You can review his online undergrad portfolio book at: http://issuu.com/andrewberno/docs/berno_portfolio.

Did you always want to be a designer growing-up? What is it about design that keeps you so passionate?

Hi Jon, thanks for the Interview. As for always wanting to be a designer, this was not my case.

Hi Jon, thanks for the Interview. As for always wanting to be a designer, this was not my case.

As a early teenager I was very interested in music however today I can barely remember the name of a song or its artist. Later on I was interested in a few other potential careers and also nearly joined the defence forces, however the entrepreneurial spirit, wanting to travel and have my own business one day, I choose not too join.

As for design, I always enjoyed the creating of objects, from Lego, paper boats, wooden swords to gokarts and peddle prix vehicles, so it was this enjoyment of making things that pushed me towards design. Plus there is a lot of cool designed stuff and I want to be a part of that.

You attended a number of engineering schools getting your BA in Industrial Design from the University of South Australia and most recently got your SolidWorks professional certificate. How well did all that schooling help you with your designing? Are there any aspects of it that in hindsight you could have skipped and it would have had little effect on your current abilities?

Well I’ll have to say that when I was younger I was way more artistic and creative, and through my past experiences and situations I have become more rational and practical, and lost some of that creative flair.

Working with my father when I was younger and then assisting with the businesses when he was hospitalised I had a lot of exposure to heavy industry, steel fabrication and manufacturing. This has giving me a great grounding knowledge and skill set as a product developer, however my Industrial Design university degree certainly gave me exposure to other design fields.

It’s hard to say what I could have skipped, but I do know that through my studies I have been exposed to different ideas, thinking, fields of design, etc, that has been amazing. The only thing in hindsight is that I should have pushed myself more in courses and skill sets that I knew I was poor in just to bring them up to a level I would be happy with, but for courses I think that any further knowledge and training is a good thing, sometimes the hard part is choosing which ones will be the most beneficial to you.

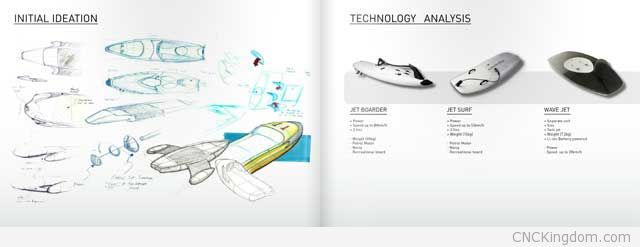

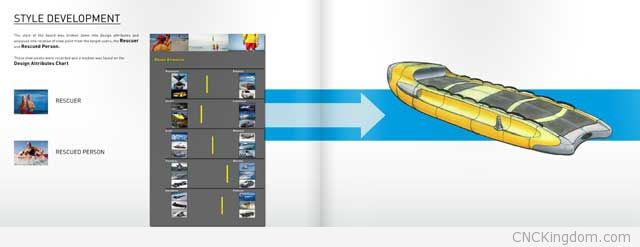

I’m incredibly impressed with your surf ski concept, can you describe the project in a little more detail and if you’ve been able to license the idea to a manufacturer to build and sell it to save lives around the world?

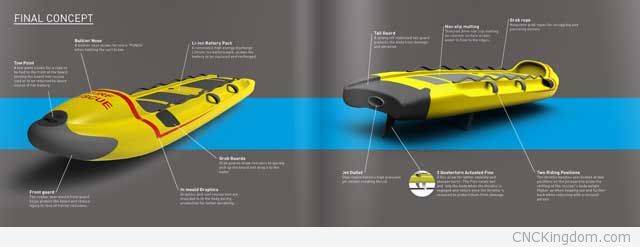

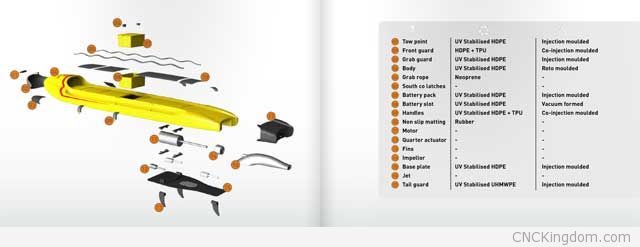

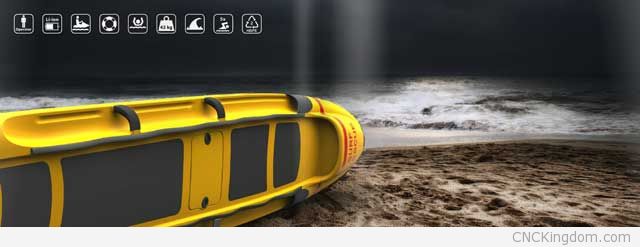

Well cheers Jon. Yeh there was a lot of work put into it plus also learning/developing some of the skills to build and show case it. The concept was just a rescue board for surf life saving clubs, which was allot cheaper than a jet ski, quicker than a paddle out board and didn’t require a huge amount of retraining for the volunteer surf lifesavers to use.

Originally it was aimed to be just a portfolio piece that would get me good job upon completion of my degree. However from a number of peoples feedback there has been some interest in it but its still needs allot of investment with prototyping. However I wouldn’t mind coming back to it in the future at some stage, just too see what its potentials is, unless you know some people who would be interested to invest/partnership with further developing it.

Your Fossick chair is incredibly beautiful – how long did it take from initial concept to finished product? What were some of the challenges involved with mixing three different materials (corian, jarrah and aluminium) together?

After visiting the Milan Salone del mobile in 2011 I was just caught up in the entire atmosphere and wanted to work on a furniture piece/collection. Once I returned, I had a furniture elective at uni and a mate was putting together a design exhibition so this was the perfect time to work on it.

The material inspiration I got from my parents kitchen top which has had Corian as the bench top for nearly 28 years. Also I was intrigued to play with thermoforming. I think over all it was over 3 months to be at the current design; however I would say it’s not finished and I will defiantly come back to it at a later time when I have some more resources. The main challenge is the material connection to each other.

Engineers love their CNC machines – which one are your favorite to use and why? Any other tools that you love to work with in the creation of your products and projects?

After completing a CNC operating/programming course at Tafe SA I have had experience with some mills and lathes. CNC routers is what I have used most of, especially during my university degree. The very fast CNC laser cutters a amazingly scary in their speed but a twin spindle 7 axis lathe with live tooling was a machine that really impressed me from a production perspective.

You worked for a number of engineering firms in various capacities over the years, what made you want to jump ship and start your own company three years ago?

Well my own company was basically a way for me to fund my own projects and act as a CAD monkey contractor. A way to get a start in the industry, for now I’m still eager to travel around the world working for others, just to meet new people, future contacts, gain exposure to different design thinking, skill sets and industries. But the aim is to come back home and then fully focus on my own business ventures.

For somebody who isn’t familiar with SolidWorks (I use 3DS Max for my designing), how long it take you to become fully proficient in this software and are you still learning new tricks and tips? Can you share a few with me?

Well I used CADDSMEN back in high school and became reasonably proficient in wire-form modelling. Once I was at university, SolidWorks was the program available and it took me a good year or two, to change my way of thought and approach to parametric modelling, but now I couldn’t go back.

To become fully proficient I spent many, many hours frustratingly rebuilding models during projects, trying different approaches, different features, etc, just to get to my end result.

My jet powered surf rescue board was a project, that painstakingly, I self taught surfacing modelling with SolidWorks. After that I received a training award from a local re-seller.

These courses didn’t teach me much new, a few productivity tricks but mainly it gave me confidence that what I had self learnt was correct. One thing I picked up was that most users only use about 20 percent of the tools available, 80 percent of the time.

Knowing how to get to your end result and what the future of that finished model is required to do, along with a understanding of majority of the features available will change your approach and save you time. Recently in Germany I worked mostly on surfacing complex plastic parts. My tip for this is to build using a master part to control the overall design intent (sometimes with draft included) and using a large number of base sketches that control points for you to reference off. Then splitting the parts up in to separate models and working on them to develop the details.