Amanda Bahari: President at Infinite Quest Cabinetry (USA)

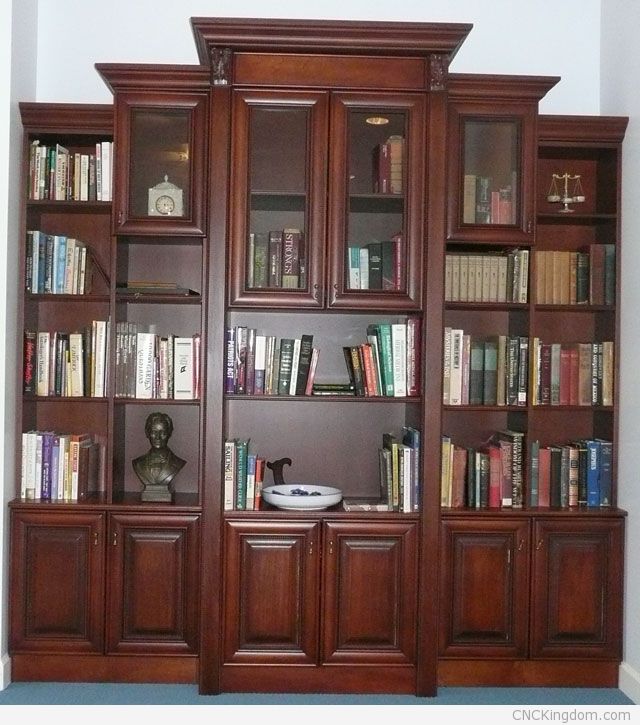

Amanda Bahari is the President at Infinite Quest Cabinetry which is based out of Baltimore, Maryland focusing on custom built cabinetry. She employs a team of highly trained and skilled professionals who produce some awesome work as you’ll see in the pictures found in this interview..

You can contact Amanda at http://infiniteqst.com.

When you got out of University, you seemed to have headed right into management positions, how well did those experiences at Gateway, CDSI and Vartta prepare you for managing Infinite Quest Cabinetry?

I actually was in management before college, I knew all about sales and production management from my previous experiences. In many ways I was well prepared for Infinite Quest Cabinetry, however the economic downturn made for some challenging times. At that time we began analyzing different business plans for viability. Our initial plans were scrapped and we manufactured a wider variety of products.

What kind of equipment both hardware and software wise, do you use primarily to produce and manufacture your cabinetry designs?

Software: Basic designs are either KCD or autocad, and excel is used for sizing of some components.

Hardware: Features a wide array of manufacturing equipment. Since we are a full custom shop, we manufacture all of our doors, and components. We have weeke and cms cnc routers, various solid wood equipment (planers, sanders, shapers… ), a laminate line, case clamps, and finishing room.

I also have to ask, what’s does this machine do – is that a massive drum router?

This is a cms cnc router with an 8 head tool turret. Wonderful machine used in manufacturing components for cabinets as well as doors, countertops, and at times in the past it was used for drawer box components.

What types of woods (engineered and natural) does your company primarily use and how many employees and square footage do you have in your production area?

We use a variety of wood products, and since there is such a wide range of requirements for projects we may be using plywood on one project and low emitting melamine on another. Our wood doors are manufactured in what ever the client’s tastes and needs require. We manufacture in all the standard species: Maple, cherry, oak, poplar, saepele, beech, walnut. And we will do custom cuts such as a rift cut poplar to satisfy a particular look.

The manufacturing space is around 8500 square foot and we average around 4 to 5 employees.

How long does it typically take to go from customer request to finished product in their home and what are the steps involved in making everything run smoothly?

The time for each project depends on the complexity. Sometimes we will spend several weeks on a design to get it right for the customer to approve, but there may be more manufacturing drawings required for the more complex projects as well. On average 6-8 weeks for a higher end project, and complex projects can be as much as 12 weeks.

a. The most complex step is determining the customers needs, and creating drawings that will satisfy those needs and requirements. My project manager has training as an architect and I have had design training as well. So we both work on the drawings and this process can take as much as a month.

b. Determining the materials, sometimes this is easy but othertimes we will spend several weeks evaluating options in materials, hardware and finishes needed to create the look.

c. Actual manufacturing – with drawings, hardware an material defined, manufacturing can go smooth.

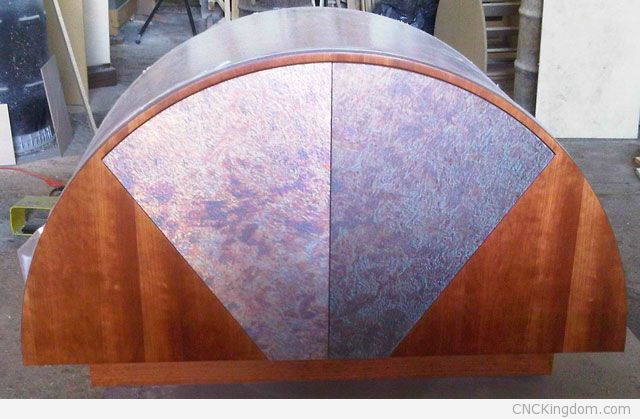

What are some of the more exotic requests you’ve received from customers? Do you have any projects that really stand out of the ordinary?

a. We created a custom bar for a client. He wanted something where his family could enjoy. And he wanted space for a fish tank. the upper countertop was a curved led lighted corian, we created a backpainted glass backsplash, there were glass cabinets that featured back painted glass to conceal the contents, and we used recessed metal pulls, some of the pulls had the led switches concealed on them.

b. A current project we are manufacturing features an island that is over 15′ long. The two ends are circular seating areas, the back side features corbels, and the toe kick areas are lit with rgb leds.

You have many really beautiful cabinets and woodworking projects on your site – how do you find most of your customers and do you work mostly locally or across the US with distributors and resellers?

My clients find me through word of mouth. During the economic downturn many of the kitchen dealers whom i previously worked, either retired or went out of business. I have remained busy and I am just beginning to advertise. We have been mainly local to Maryland, DC, Va, and Del.

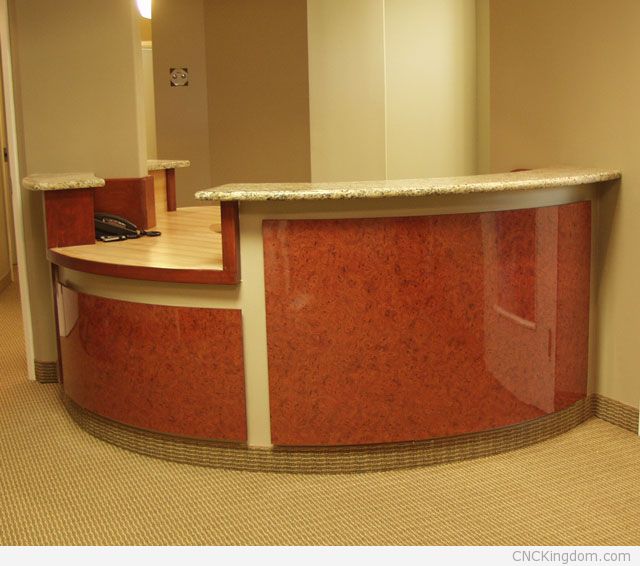

Cabinetry isn’t just for kitchens and living rooms, you also build display and retail fixtures, healthcare and even restaurant cabinetry and accessories. Which areas have the highest growth potential and which markets are the most challenging to serve?

The healthcare market and restaurants have very high growth potential. They can all be challenging to serve. There is a wide variety of material requirements for projects these days so reading the fine print is a must and you have to contact all your suppliers for availability and pricing.

Anything else you’d like to add?

The economy has begun to move again and for Infinite Quest Cabinetry there is a world of endless possibilities.