Adam Cirkic, CEO of Tangenta (Croatia) ~ CNC Nesting Software

If you do any amount of CNC plasma, routing, waterjet or even laser cutting – you want to get automatic nesting software to greatly reduce the amount of scrap you produce while at the same time, cutting efficiently as time as money. The more you can cut on one sheet, the more you save!

You can find-out more about Tangenta by visiting them online at tangenta.hr.

Where did your interest in CAD/CNC come from? How did you learn about these machines and their related design software?

I worked as CNC plasma cutter machinist in HVAC 2 years. This HVAC company used ventilation ductwork software but nesting goes manually. I programmed plugin (custom radius elbow) that improved fitting fabrication in that company, also I was good in manually nesting.

Can you tell me how Tangenta got started and what is your vision for the company overall?

I ‘m founder of Tangenta Ltd. (2009) as 8 year experienced database programmer and metal fabricator. After CNC HVAC experience I decided to start with something new and more interesting – CAD/CAM software. Tangenta main vision is industry related CAD/CAM software or plugins.

For those unfamiliar with nesting software, why is it needed and how much of a savings in material and time can they provide a company?

When company grows up and has larger projects to do, projects with deadlines, no one can be satisfied with manually nesting. When company handle over 15 sheets daily it is very frustrating for CNC operator to handle it.It is more obviously when company is fitting fabricator or other product supplier.

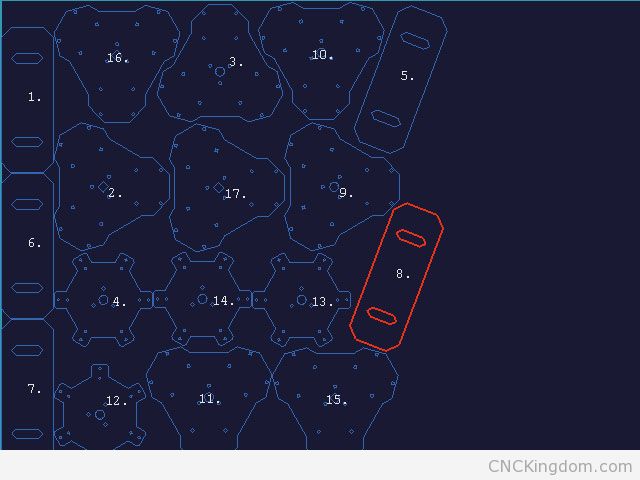

There are different kind of automatic nesting software on the market. Basic automatic nesting can handle only rectangular shapes.Some other can nest simple (regular polygons). Advanced automatic nesting software successfully nest all kind of geometric shapes and provide ‘in holes’ nesting.

Top true shape automatic nesting software provide all kind of geometric shapes nesting, ‘in holes’ nesting, multi sheet nesting, multi sheet (different sheet sizes) nesting, scrap database management and scrap multi nesting.

Manual nesting has advantage when CNC operator has small number of parts and enough time. For larger manufacturing automatic nesting has advantage.

Automatic nesting with strong algorithm can do faster and better nesting than CNC operator/machinist. Our tests shows that automatic nesting can be 2-3 times faster then manual and material saving can be 10-15% better than manual. It can be more if automatic nesting software support scrap nesting.

If somebody develop chemical ship with duplex steel, which is a very expensive material, he can easy calculate how 10-15% (after each nesting session) reduce material costs.

Ironically, I’ve been using PartWorks (CNC Router Vectric Software) for over two years and only last week discovered automatic nesting… WOW! That’s amazing stuff after doing it manually but it still has its quirks requiring me to manually review each “sheet” for optimal settings for things like tiling and tool paths. How is DG Nest + and Pro different than other nesting software solutions out there?

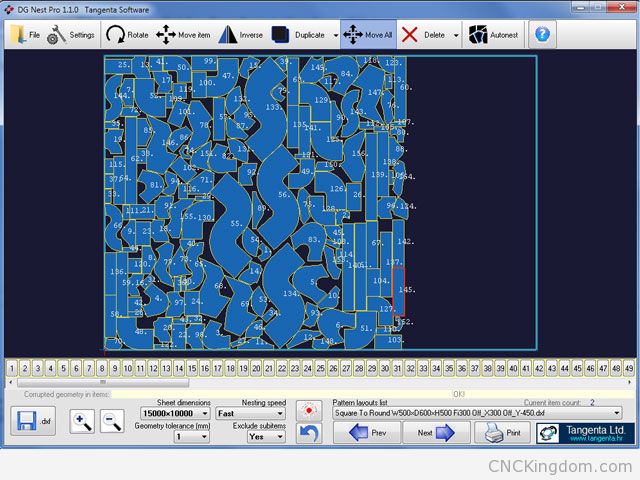

‘DG Nest Pro’ is full manually and full true shape automatic nesting software. For professional users ‘DG Nest Pro’ collaborate with ‘SheetCam’, popular CAM software, through DGNestPro/SheetCam plugin.

Before user load dxf files directly via DGNestPro and start nesting, he rather choose SheetCam to create cut paths and other CAM settings, then he can export SheetCam dxf to DGNestPro for nesting.

All parts will be nested considering that cut paths, leadins/outs and loops will not be overlapped. SheetCam support dxf format and 180 other post processors.

What are some of the most common problems with automatic nesting and how does your software solve them? Can you give some examples?

In most cases they has poor algorithm inside which are not multit-head oriented. They can’t do parallel multi-nesting on more sheets in the same time.

They can’t do nesting in different sheet sizes at the same time. Most of them do not support scrap sheet nesting.They generate universal G-code which

not customized for every CNC controller.

Software price can be crucial problem, we offer advanced true shape nesting for less than $1400! For the same functionality competitors offer their software above $1500 and in some cases above $2500.

I really enjoyed reviewing your blog – lots of awesome nesting pictures and it seems like you support ShopBot Tools as well along with TorchMate and Thermwood to name a few others. Does your software need to be optimized for the CNC machine type (plasma vs laser vs router) or is nesting basically the same regardless of cutting technology?

Our SheetCam CAM partner software support plasma, laser, water jet cutters and 180 post processors (machine controllers types). Tangenta Ltd. provide advanced true shape automatic nesting. This two modules DGNestPro and SheetCam make unbeatable combination.

This is a full list of supported post processors:

AB tube cutter

Allen Bradley 8400

AllenBradley

AllenBradley2

Amada laser

Amada laser2

ANCA laser

ANCA2000

Anilam

Anilam2

Biesse Rover XNC

Biesse Rover

Biesse

Bosch CC100 router

Bosch CC100

BOSS5

Bridgeport 32dx

Bridgeport V2XT

Burny25 inc

Burny5 inc with plate marker

Camsoft plasma

Centroid

CutMaster_v3-1

Delta Tau waterjet

Denford PCNC

DeskCNC plasma

Dialog4

DXF

Dyna DM2100

Dyna DM2400

Dyna6KTHC

Dynapath conversational

Dynatorch no feed

Dynatorch router

Dynatorch

EasyCNC

EaziCNC plasma with THC

EaziCNC plasma

EMC -Laser post-plasma mod

EMC lathe

EMC plasma – laser

EMC plasma

EMC

Esab vision 1000

Esab vision 3pos

Esab vision 500

Esab vision

ESSI noarcs

ESSI

Excellon

Ez-Scribe5

EZ-Trac

Fagor 8025M MotionMaster Router

Fagor Router PAUL-FINAL-Z

Fagor Router

Fagor

Falcon

Farley Rapier

Flashcut plasma no Z

Flashcut plasma

FlashCut

Flow omax ord

Flow

Generic plasma with optional scriber

Gerber Sabre

HAAS TM-2P inc arcs

HAAS VF3 inc arcs

HAAS VF3

Heidenhain TNC150 conversational

Heidenhain TNC150

Heidenhain TNC530 conversational

Heidenhain

HPGL 3D

HPGL no arcs

HPGL

Hurco Ultimax

Hypertherm edge

Hypertherm Microedge

Innerlogic

Isel RG5996

Isel

IselV2

jetstream

Kinetic Touchcut

Klymit

Linde CM350

LinuxCNC THC

Mach tube cutter

Mach3 2 heads

Mach3 2D

Mach3 flame with THC – G31

Mach3 G42 experimental

Mach3 plasma no Z

Mach3 plasma pauses

Mach3 plasma Rutex

Mach3 plasma

Mach3 tangential 180

Mach3 tangential with 3 heads

Mach3 tangential

Mach3 THC with scriber

Mach3 XCZ

Mach3

MAHO MH 600

Mazak L32B

Microstep

Minimum G-code abs arcs

Minimum G-code no arcs

Minimum G-code non-modal

Minimum G-code

Mitsubishi laser

Motoman

MP1000-THC

Multicam

MyTMill

NC studio

NUM laser

NUM laser3

NUM plasma

OSAI plasma

pCut

Picopath inc

Plasma THC300 – G31 – corner slowdown

Plasma THC300 – G31 – lift for delay

Plasma THC300 – G31

Plasma THC300 forceheight

Plasma THC300 start marker

Plasma THC300 with scriber

Plasma THC300

Plasma with plate marker

PlasmaCam

Prototrak Edge

Quickstep plasma v2

Quickstep plasma

Quickstep

Roemtech

Roland CAMM3

RoutOut

Sentrol2 Plasma

Shopbot plasma

Shopbot reversed Z

Shopbot

Siemens laser

START

StartDrill

SteelTailor inc arcs

SteelTailor

TeknoThc 160V2

Thermwood 2 heads

Torchmate plasma THC

Torchmate plasma V2

Torchmate plasma

Tormach Inch RG-G

Trumpf L250

Trumpf TNG

TurboCNC non modal

TurboCNC V4 with G83

TurboCNC V4

TurboCNC

USB-CNC

USBCNC

WinCNC FL

WinCNC Plasma THC

WinCNC Plasma V3

WinCNC

Wingnc

Woodstep Ima

Xilog fixed exp

Zinser CNC920

Zinser

Where do you see the biggest growth potential in the nesting industry? What direction is it going in the future?

It is hard question for me, I’m not industry analyst but consider on 2D metal, glass, wood, textile sheet based industry nothing will replace classical manufacturing in future. That means that market is still open for nesting type software in future.

What are some of the more cool projects you’ve seen your software used to help build?

Ship building and ocean-liners.

You can find-out more about Tangenta by visiting them online at tangenta.hr.