3D Systems Cube: Angular Surprise!

Before I got into 3D printing with my 3D Systems extrusion Cube, logic would dictate that anything over 45 degrees wouldn’t be possible as the material would fall to the ground after it went over the edge… you can’t have floating material.

This logic stood and the only time I questioned it is when I realized how much I hated using support material… if I would have had a multi-head 3D printer, this wouldn’t have been an issue as I could just easily dissolve it away but with my Cube, the support material is the same as the model material rendering this impossible. Watch this video to see what I learned.

https://vimeo.com/204710989

So, I decided to make Noe’s last model he gave to me to sell here on CNCKing.com without any support material – I was astonished! Here is the result.

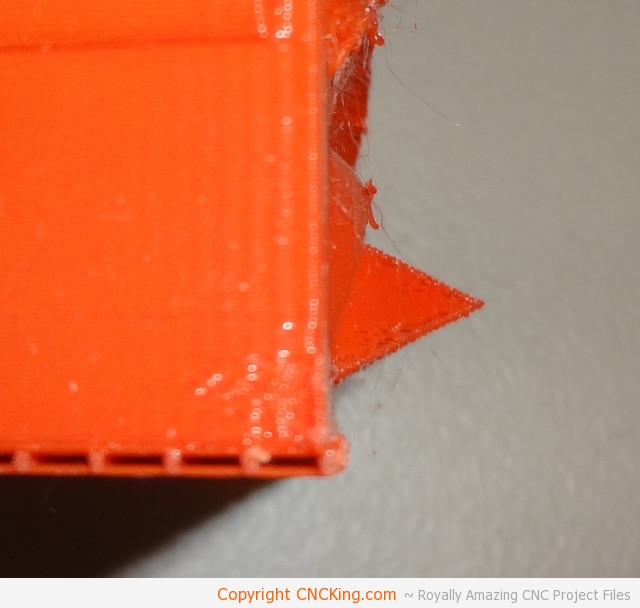

It looks amazing! All done without support material… but my focus was on the chin, I was 100% sure it would fall flat due to the angle but here’s a close-up. Y

ou’ll notice the upper lips, just below the eye balls and the nose flarings weren’t as lucky, we are dealing with extremes of 3d extrusion capabilities here but consider for a moment – this was made at home with a printer costing less than 2K – not a massive industrial machine costing several orders of magnitude more!

What angle did I achieve with my 3D Systems Cube on the chin? Try 30 degrees! If you look closely, there is some “hanging on” and it’s not as solid as the rest of the model that’s completely vertical but we are talking about a full 15 degrees of extra design freedom that I was certain I wouldn’t have access to using extrusion. That’s 1/3 more!

That is significant, it means having curves that can can slowly bend upwards instead of going right at 45 degrees against a flat surface. It means being able to make inside pockets, like the ears of this model, without needing support material at all and most of all, it means I can do so much more without having to worry about having to even consider using support material!

If you look at this 3D assembly animation, it looks great – everything is PERFECT… that’s all well and nice as I don’t have to deal with gravity, surface cohesion or a host of other issues that could make a model that models well virtually, into scrap in reality.

This is the biggest single challenge right now in the area of 3D printing – 3d modeling is a steep learning curve but so is understanding the limits that you must adhere to, from all angles, accounting for nature’s forces, to make a design possible in the real world.

I’m very happy with Noe’s design, I’ve learned so much from this experience – and it lead me to try new things that I had previously never considered. I’ve already added three to CNCKing.com and will be adding the forth shortly.

As I’ve found throughout my life, the unexpected problems usually lead down roads that had previously been hidden from mind – if everything always goes the way you think it should, then there wouldn’t be any growth.