3D Systems 2nd Generation Cube 5-Month-Printing Review

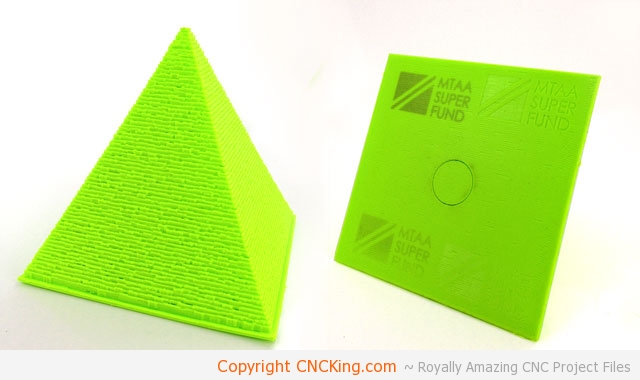

When I first got the 3D Systems Cube, I was very happy that the very first project I designed worked so well… I was sure it was going to have trouble but my 3D Printed Egyptian Pyramid came out great! I then designed and printed quite a few things which you can see in the 3D printed section of CNCKing.com.

I strongly suggest you give this a read first of my initial impressions after using the 3D Systems Cube for a few days: http://cncking.com/3d-systems-2nd-generation-cube-review/

3D Systems Cube: What’s Great

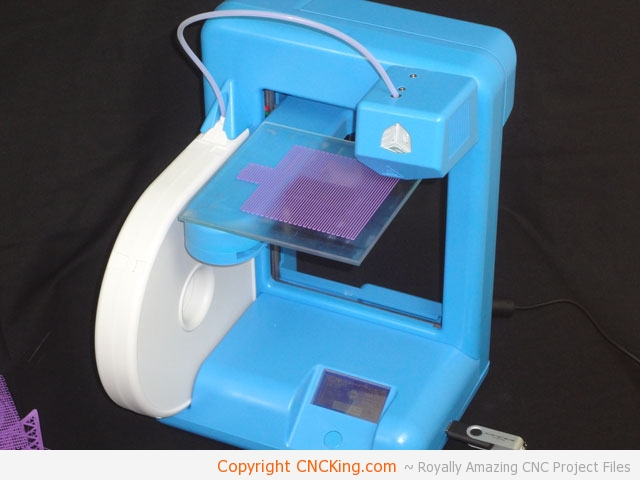

What I really like about the Cube is that generally, it prints what you tell it too without much fuss but what really make it stand-out compared to a CNC table router or laser cutter / engraver is that it can run in the house without concern for dust or debris. Because it’s an a additive technology and not a subtractive one… it’s nice not having to load and unload the machine before and after each job. You really do just press print.

The form factor is small and fits nicely in the corner of a room I have set-up for video production – not something I’d ever do with lasers or routers. I like the potential this technology has in that if I need something, I can MAKE IT and USE IT right away, without having to drive all over the place to look for parts.

Call me lazy, but I haven’t even needed to calibrate the platform or any other aspect of the 3D printer since I did so back in the end of March… everything stays together perfectly – I do check it visually but overall, no problems. It might be small but it’s sturdy!

At first, I really saw the cartridge system they use as a handicap to what else is out there (mostly spooled 3D printers). I have been caught a few times where I wanted to print something and the cartridge didn’t have enough material in it to do the job – at least it told me so which is nice – but what I’ve done around this is just print at a smaller scale OR print / design something different that did use-up the rest of the cartridge.

I remember years ago I was annoyed that laser cutters couldn’t bevel or cut at right angles (45 degrees vertically, only and always 90 degrees) and since then, I’ve realized you actually can but it takes multiple passes and not really needed anyhow – I’ve come around the same way with this 3D printer. It has limits, but those limits aren’t as severe as you think at the onset.

3D Systems Cube: What Sucks

Other than the small print size (within industry norms at this price point) and not being able to make full-blown 3D printed toys with moving parts and negative spaces (that’s what a SLA / zPrinter is for) my complaints may seem trivial.

It took me months to figure-out where the on/off switch was – sure, I found it in the instructions book since but who reads that? They should put a on/off power button icon on the big round thing under the LCD panel! They think too highly of my intellect to figure this out on my own.

Another complaint is that it’s too quiet – I have it working in the other room and on a regular basis, I get scared because I don’t hear anything… only to see it 3D print away. I’m use to LOUD industrial processes, not this quiet stuff… where quiet generally means something bad has or is happening. There should be some kind of beeper that goes out saying either “All is fine” or “Run out of the house”… but silence… arg!

I got a box full of this stuff – no, it isn’t what I wanted… it’s what happens when you try to 3D print something and it gets unglued from the platform. I remember when I was at 3D Systems and they had a heck of a time getting a model OFF the platform using the special glue and heated surface – they swung the other way with the second generation Cube – stuff gets unstuck. Sometimes it’s my fault (too much or not enough glue), sometimes it’s the model and sometimes it’s a software problem. Oh yeah, you have flow errors etc. to content with as well but this aspect of extrusion 3D printing (they ALL have this problem) isn’t something I like.

A lot of these screw-ups though, to be fair, can be isolated to a bad mesh… I’ve learned a lot thanks to my 3D Systems Cube and have brought down the number of times this happens down dramatically. I also do not use their software to design (may be a factor) and try things that have most likely never been done or tried before on their 3D printer. For instance, they give you a designer pack of 25 or so meshes, I thew those out and loaded their USB stick with my stuff right away. So, don’t let the above picture scare you – I’m a very particular and special case for them.

3D Systems Cube: Surprises

Their technical support is beyond fantastic – I tell them I can’t get something to work and they will try it on their machines there! It’s one thing to have a problem, but a whole other thing to have an unresponsive staff blaming YOU for problems. If I can’t get it to work, and they can’t get it to work… then it’s my fault but they have never told me that – they give suggestions as to what should be modified and give it another go.

Considering how many things CAN go wrong, I’m always super happy when I design something and get it to work… a model might take a few hours or days to 3D print but when the stars align and it prints a model out of essentially thing air… it’s an amazing feeling!

I really haven’t released much since my Egyptian Pyramid months ago and the reason for that is simple, I’m learning how to design for it! Things look ugly, things don’t work or things are a lost cause but pushing the boundaries is the only way to learn where they are to begin with! I get rather angry sometimes when something should work but doesn’t after multiple tries when I can’t figure-out what went wrong so I punish the Cube by not using it for a week or two at a time… that seems to work in my case.

3D Systems Cube: Recommendations

Would I recommend a 3D Systems Cube? Hands down for sure… it’s a great and relatively cheap way to get into 3D printing without having to know anything technical. I don’t want to screw around with hardware and software issues, I want to print and go.

What I would suggest is that you get at least 5 cartridges knowing they will be junked – even if you buy files here on CNCKing.com that work… environmental factors can still play a role in the success or failure of a 3D print. Expect to have sticking issues as well until you get a hang of it… it’s annoying but part of the extruder’s lifestyle. I know for a fact that I will get an industrial 3D printer sooner than later – which is why I didn’t opt for the CubeX but if you want to get into multiple model colors, multi-heads and multi-materials (one support, one model) – that is the way to go.

Ah yeah… 3D Systems… please add a power icon on the big round button under the LCD – that annoyed me for months until I figured it out… and if I can put in another request – give an actual number as to how much material is left in the cartridge – a bar doesn’t tell me anything of any modeling use. Total Volume Left would be amazing!