3D Printing Projects: Why it’s important to test models

Printing my latest two models for CNCKing.com, I was reminded at how important it is to test 3D printed models before buying them yourself.

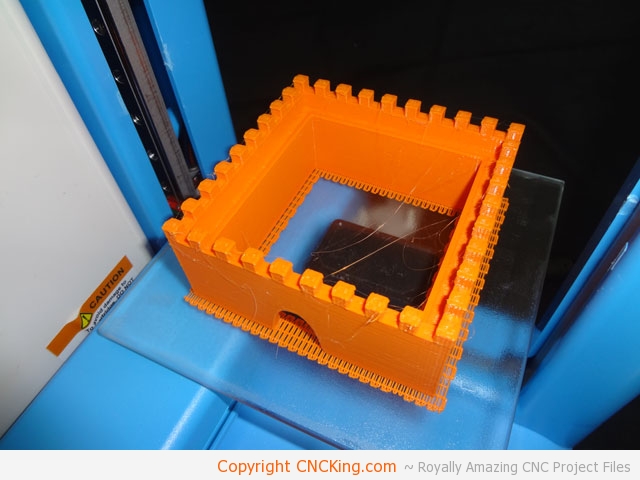

This Simple Medieval Walls project was done to test several features but the most important was the arch – can you actually print in mid-air and if so, how long can you do it before the mesh itself starts to fall and sag? The good news is that I was able to test the model here with my 3D Systems Cube and it came out wonderfully, almost half a mm without any sagging. The arch supports the top as it should without fault!

For this Simple Vase, the question wasn’t “will it work” but “how well it will work” and again, my 3D Systems Cube did a great job! There was a seam (like the previous model) but as an object, it was a successful print but not as its intended “vase purpose”. You see, I wanted to see if a “water tight” (industry term) 3D printed mesh actually was water tight, I found-out that it isn’t… no wonder the flower died in it!

Test… and learn!

This brings me to two important things that I learned from these models, without a physical test, you really know very little about what’s actually going on and how to build for your 3D printer in the future. Testing allows you to learn what you can and cannot do, what works and what doesn’t… just 3D printing a model doesn’t make you a 3D printing expert, it’s the process behind it, the failures and successes that turn you from an amateur to a guru.

When I got my ShopBot, I learned so much about design it’s incredible, the 3D Systems Cube that I have is doing the same for me… to me one is the same as the other design wise now that I’m familiar with the constraints that each technology has.